Differential type optical fiber F-P vibrating sensor with wide frequency response and high sensitivity

A vibration sensor, F-P technology, used in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problem of low response frequency of fiber-optic vibration sensors, achieve high fatigue strength, ensure contrast, and high sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

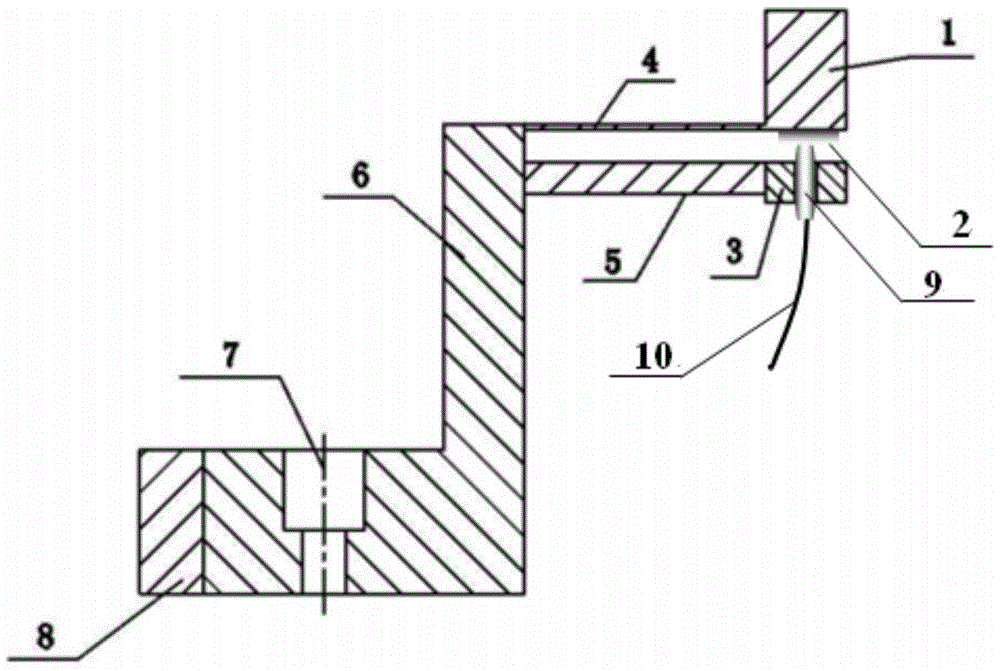

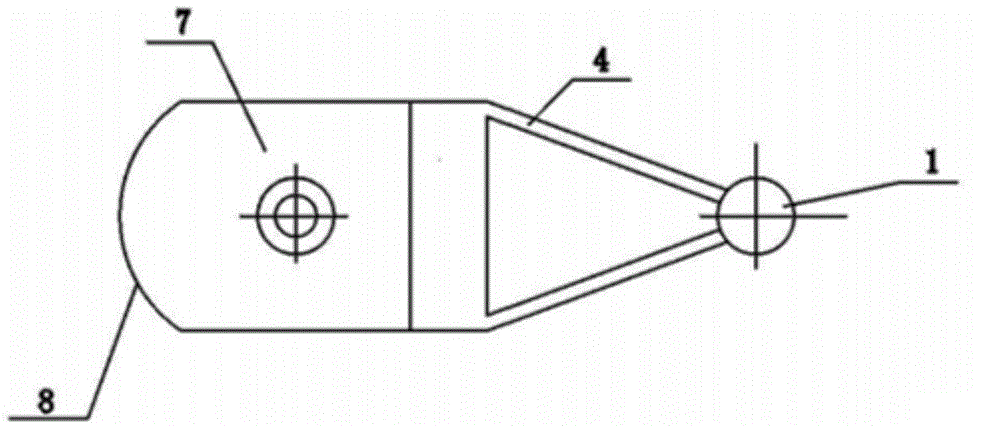

[0025] According to elastic mechanics and optical fiber sensing theory, the present invention designs a differential optical fiber F-P vibration sensor with double cantilever beam structure. The specific design principle is: through finite element element analysis, the sensor selects double V-shaped spring steel metal sheet structure, By setting the structural parameters of the two cantilever beams, the sensor has a double compensation effect of sensitivity and response frequency, and only responds to vibrations in the vertical direction, and the influence of other directions is almost negligible. Finally, through the test calibration, the basic and theoretical The analysis matches. Then, by rationally configuring the material and structure of the differential sensor, on the basis of ensuring its one-way vibration, the double optimal selection of response frequency and sensitivity is realized. Because the nature of the sensor itself is closely related to the quality of the cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com