Testing system used for three-dimensional structure internal crack propagation experiment

A technology of internal crack and expansion test, applied in the direction of applying repetitive force/pulsation force to test the strength of materials, measuring devices, instruments, etc., can solve the problems of human health impact, high environmental conditions, complicated operation, etc., and achieve high practical value , strong engineering significance, good environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

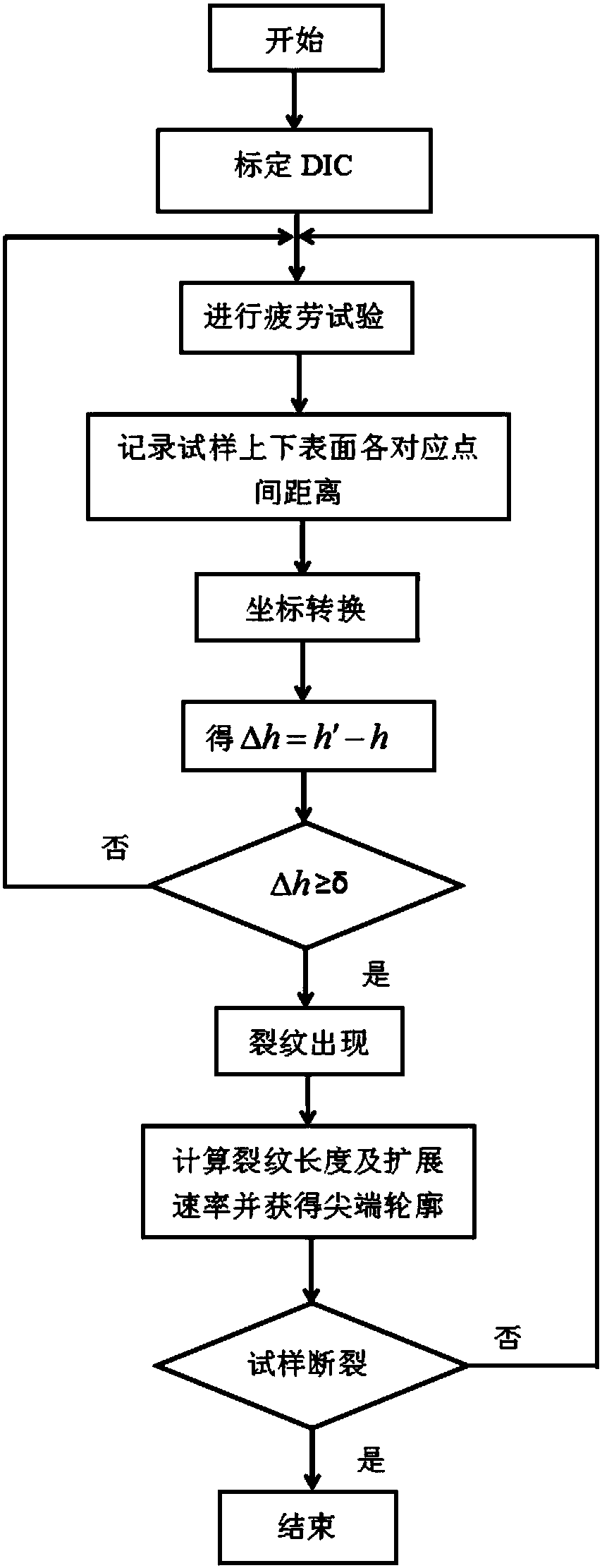

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

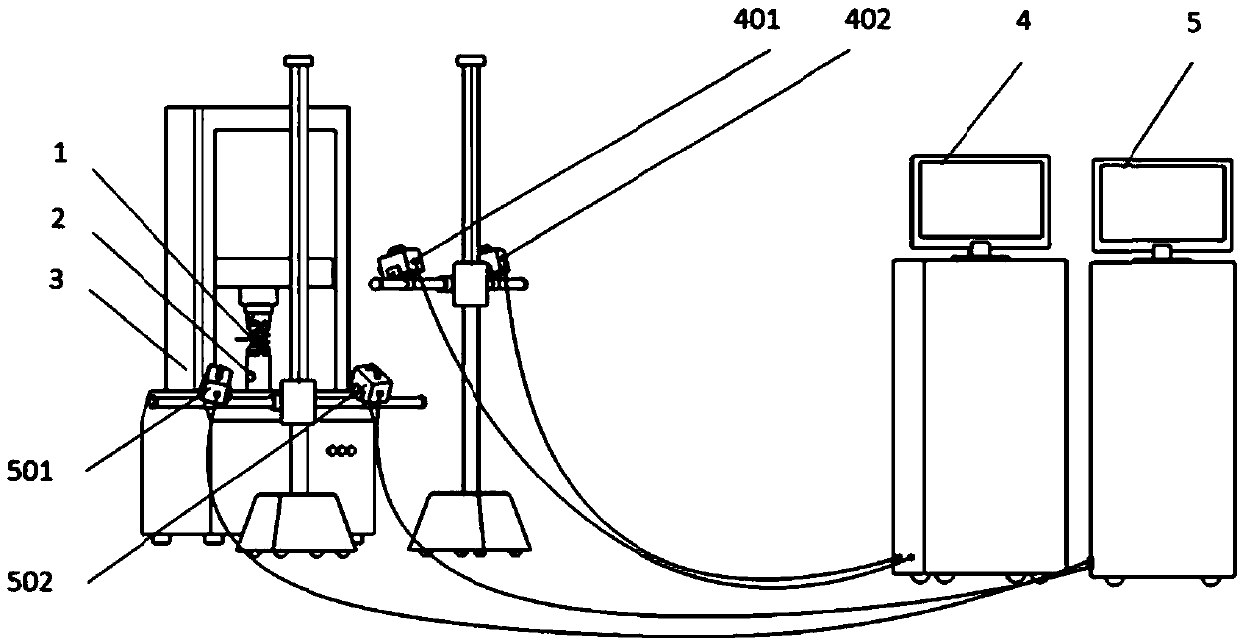

[0035] like figure 1 As shown, this embodiment provides a test system for crack growth inside a three-dimensional structure, a test system for crack growth inside a three-dimensional structure, including a fatigue testing machine 3, a fixture 2, a first DIC device 4, a first Two DIC devices 5, characterized in that:

[0036] Fatigue testing machine 3 is used for fatigue loading;

[0037] Double cantilever beam sample 1 is used as a test piece for detecting cracks;

[0038] Fixture 2 is used to connect and fix double cantilever beam sample 1 and fatigue testing machine 3;

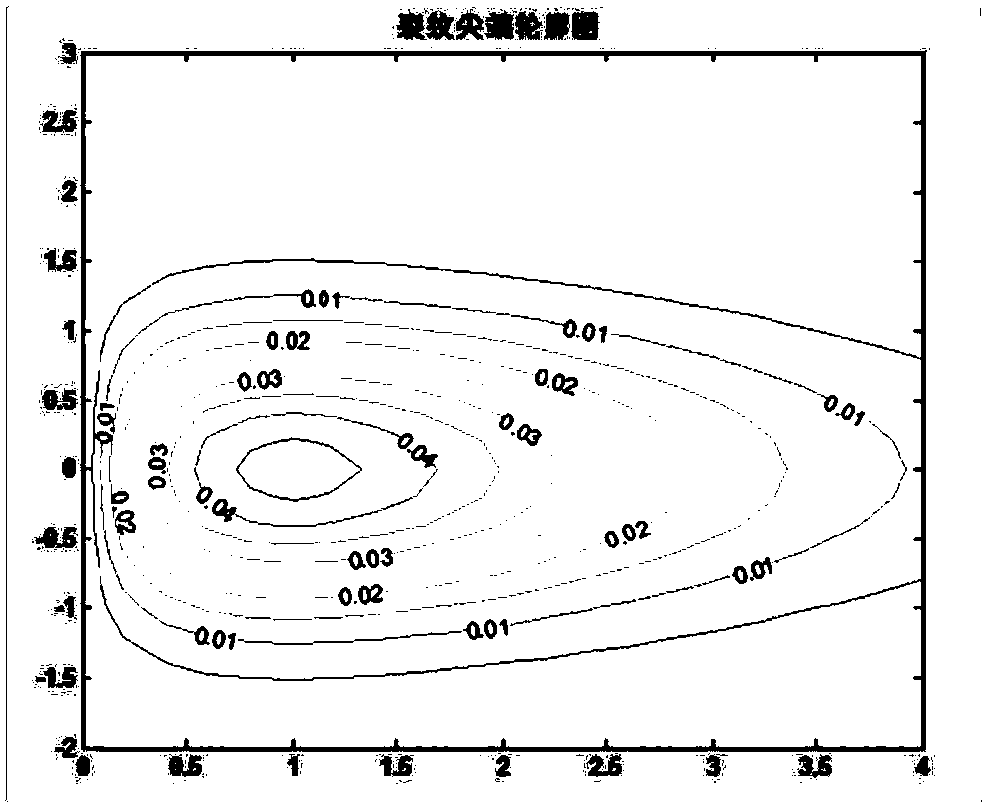

[0039] The first lens 401 of the first DIC device 4, the second lens 402 of the first DIC device, the first lens 501 of the second DIC device 5, and the second lens 502 of the second DIC device 5 are used to detect the double cantilever sample Crack tip and crac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com