Metal pipe fracture toughness detection method and system

A fracture toughness, metal pipe technology, applied in the direction of using a single impact force to test the strength of materials, measuring devices, analyzing materials, etc., can solve the problems of large errors and long detection periods, and achieve small measurement errors, few parameters, and calculation process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0082] Double cantilever beam sample DCB is currently recognized as the most accurate fracture toughness test sample for metal pipes. Therefore, this experimental example adopts double cantilever beam sample DCB to test the fracture toughness to verify the data of the present invention, specifically including the following steps:

[0083] 1. Select the same section of metal pipe in the embodiment, and make a double cantilever beam sample DCB for testing the fracture toughness according to the standard NACE 0177-2005.

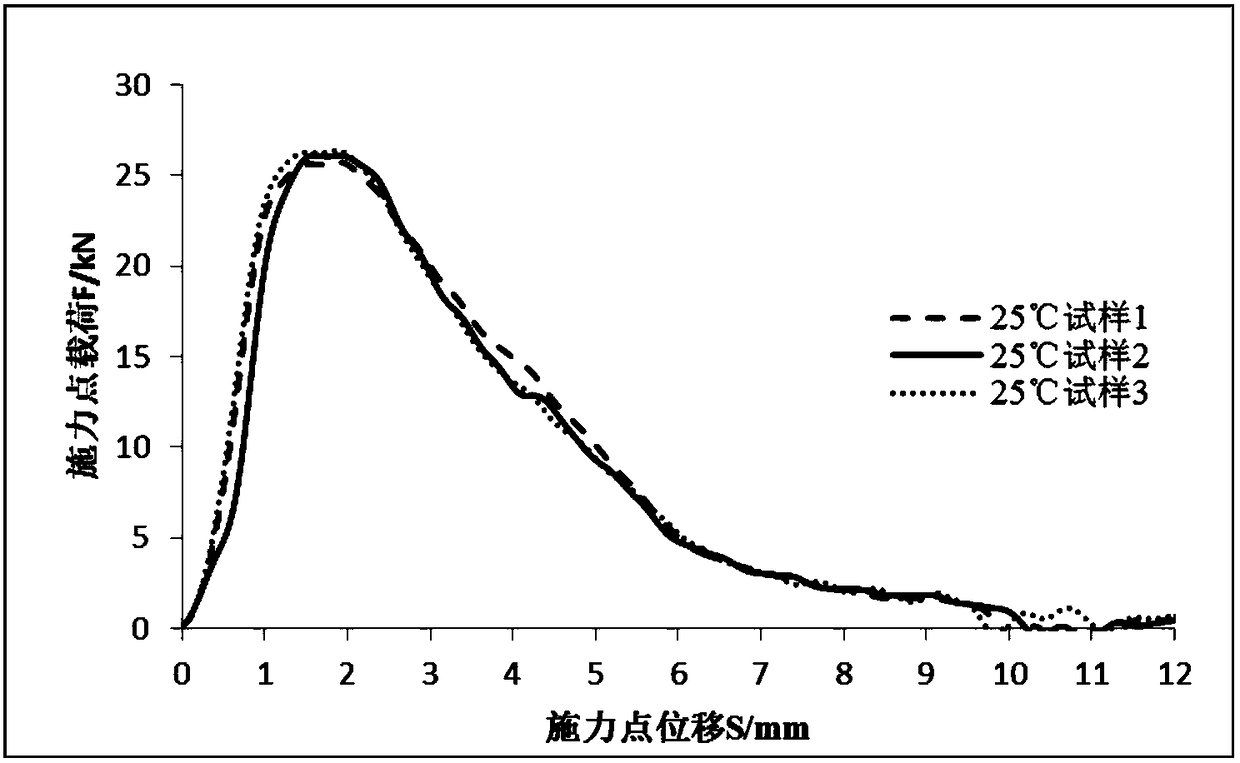

[0084] 2. Use the MTS810 material testing machine to automatically record the load F and the displacement q of the force application point under tensile loading, referring to the provisions in the standard GB / T 4161-2007, for the F-q curve of the double cantilever beam sample DCB, take FQ=F5( The slope of the linear segment decreases by 5% and the intersection point of the F-q curve).

[0085] Double cantilever beam specimen DCB fracture toughness K IC The calc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com