Double cantilever beam-coding screw rod composite sensing tensile test method and device

A technology of tensile testing machine and double cantilever beam, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., and can solve problems such as measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

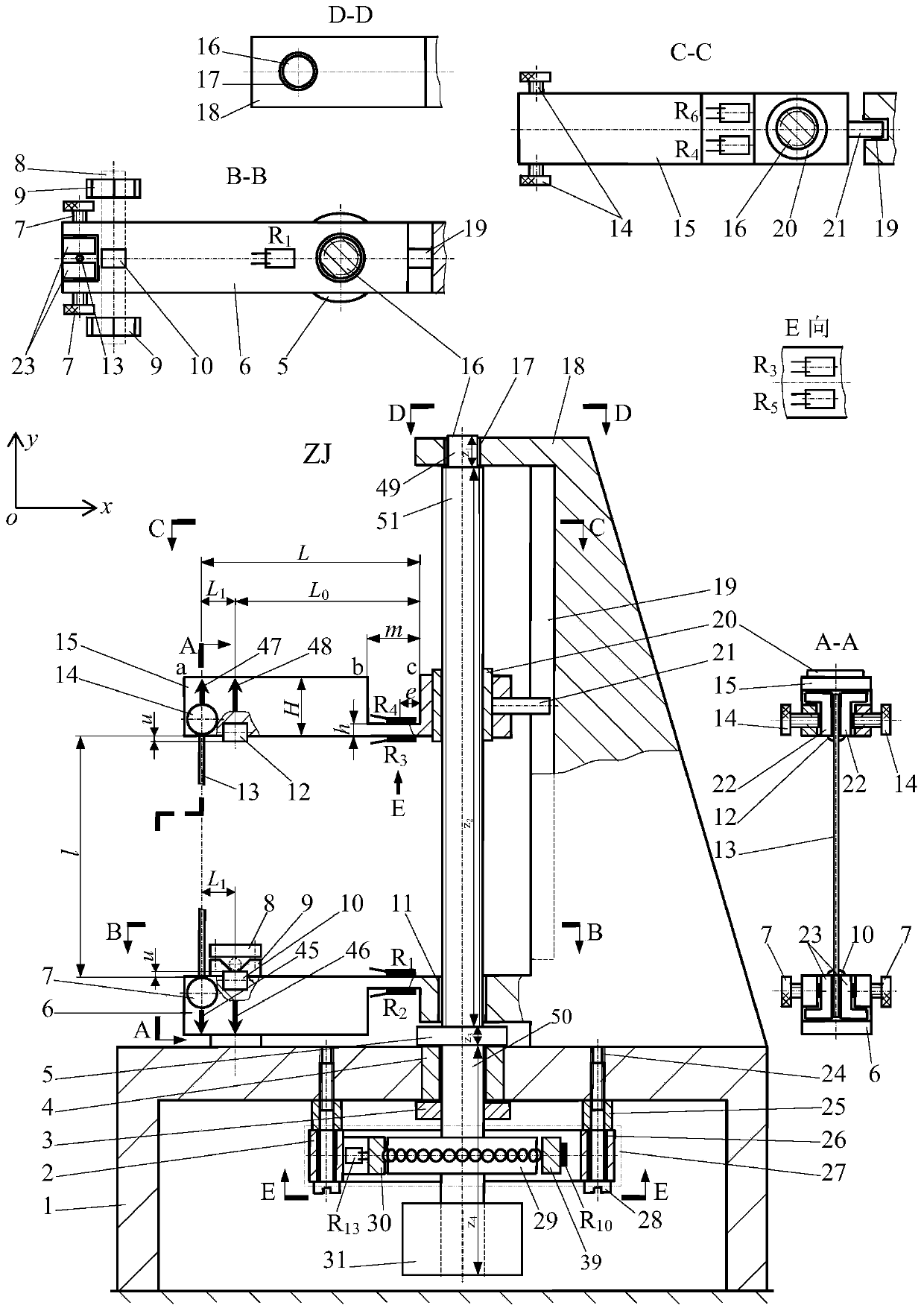

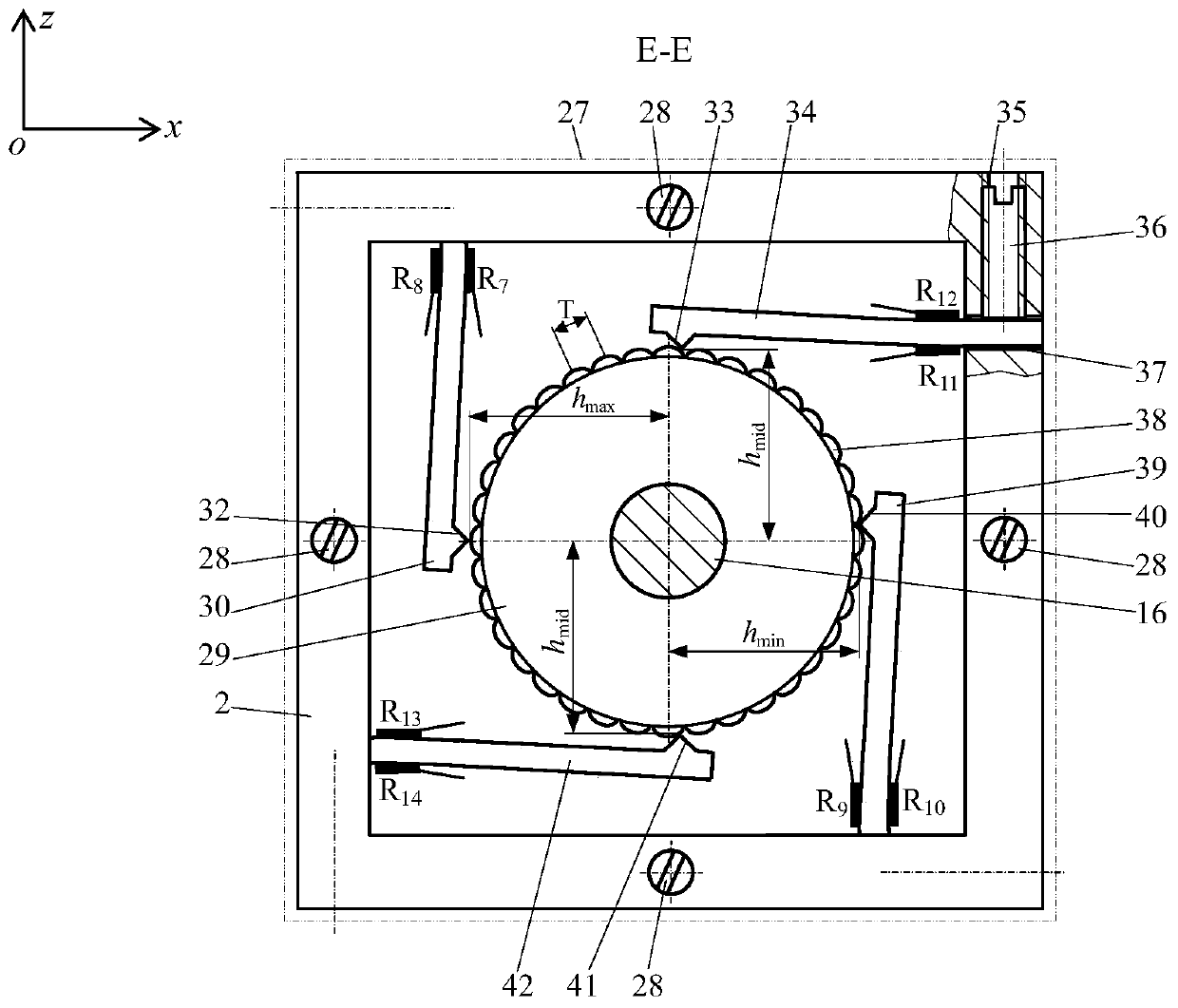

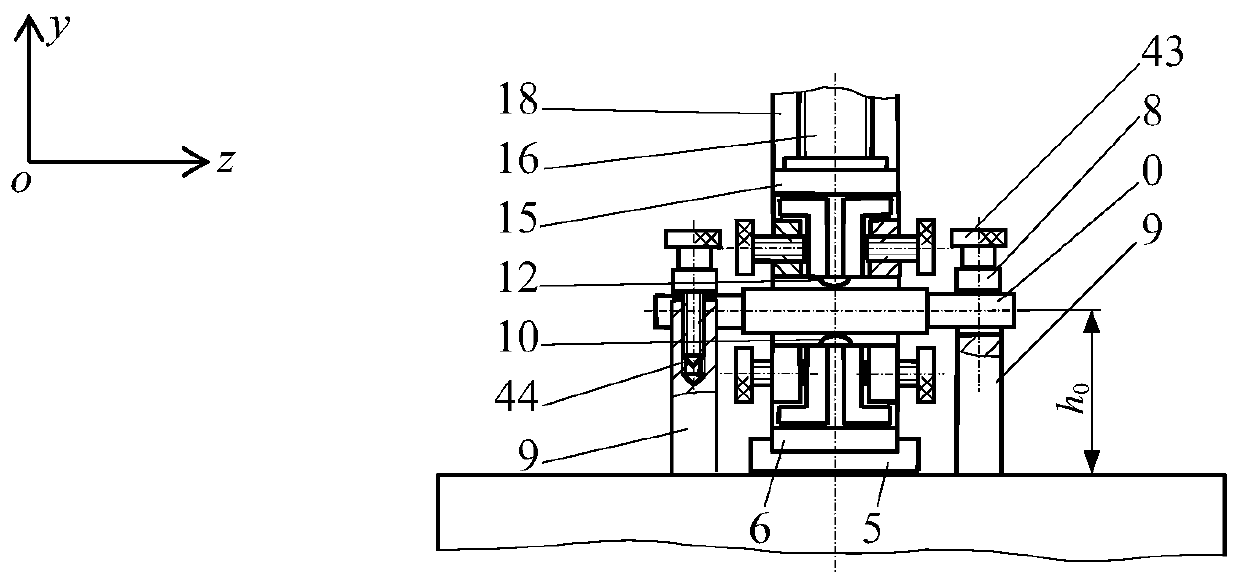

[0083] Below in conjunction with accompanying drawing this design is described further.

[0084] refer to Figure 1-Figure 7 , Double cantilever beam-coded screw compound sensor tensile test method and its testing machine, the test system is composed of the main ZJ, the standard device 0, the tested piece 13 and the numerical control device.

[0085] The main engine ZJ is composed of a base 1, a support plate 18, a force-deformation composite sensing mechanism, a driving device 31 and a positioning bracket for measuring cross-sectional dimensions.

[0086] The base 1 is a box-shaped structure, and the upper surface of the top plate is a plane. A sliding bearing 4 with an axis along the vertical direction is installed at the center of the top plate. Four threaded holes 24 are symmetrically distributed around the sliding bearing 4 . The support plate 18 is a trapezoidal thick plate, which is vertically fixed on the top of the base 1 top plate, and its right end is close to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com