Resistance strain thickness measuring device and measurement method thereof

A technology of resistance strain type and thickness measurement, which is applied in the field of mechanical test and geometric quantity measurement, can solve the problems of complex measurement system and interference, achieve the effect of simple calibration method, improve measurement resolution and ensure measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

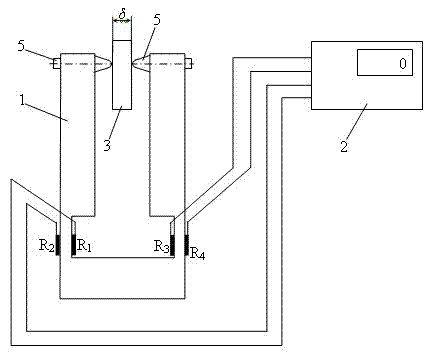

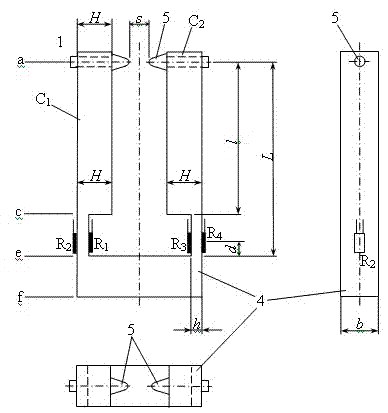

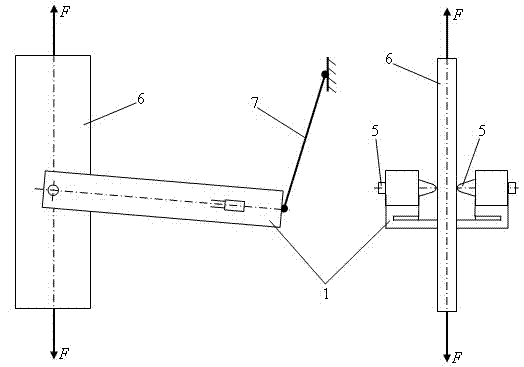

[0031] refer to figure 1 , figure 2 , the resistance strain type thickness measurement device includes a double cantilever beam resistance strain type thickness measurement sensor 1 and a resistance strain gauge 2, the double cantilever beam resistance strain type thickness measurement sensor 1 consists of a U-shaped elastic body 4, two pins with positioning pins or threads Conical top measuring contact 5 of the rod and four uniaxial resistance strain gauges R 1 , R 2 , R 3 , R 4 Composition; U-shaped elastic body 4 is symmetrical in shape, and its geometric structure includes a base ef and two cantilever beams C fixedly connected to both ends of the base ef 1 and C 2 ; cantilever beam C 1 and C 2 The geometric structure of the head is divided into two sections, the head ac and the neck ce; the length of the head ac section is greater than that of the neck section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com