Double-cantilever beam fiber grating acceleration sensor

An acceleration sensor, fiber grating technology, applied in the direction of acceleration measurement using inertial force, can solve the problems of acceleration measurement influence, poor torsional resistance, weak stability, etc., to improve stability, improve accuracy and stability, avoid The effect of fiber grating chirp effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

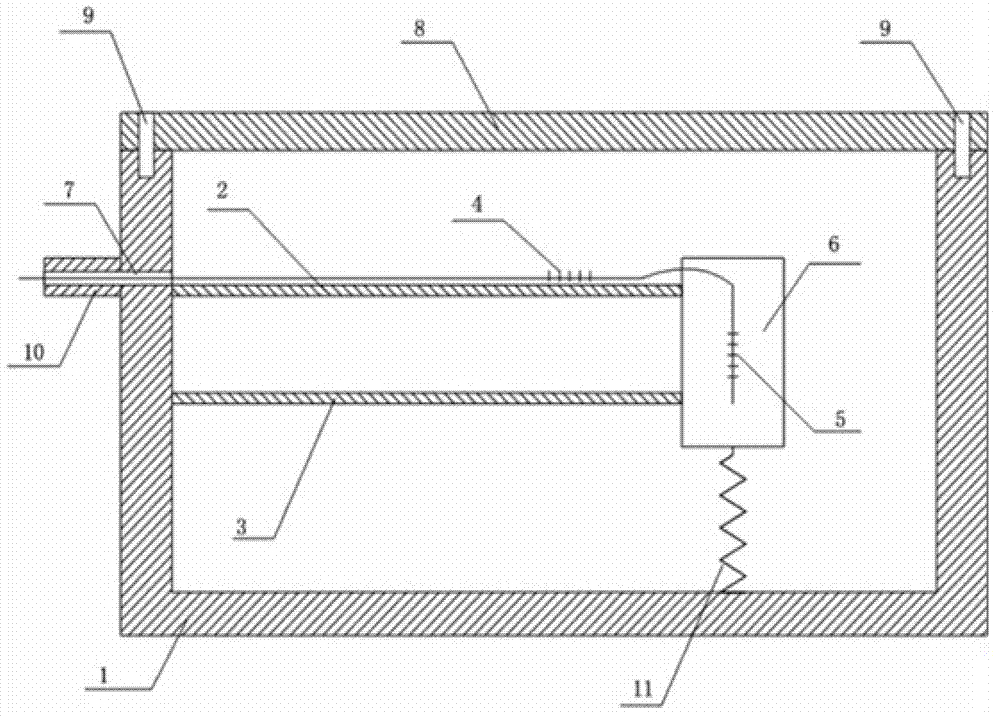

[0016] Such as figure 1 As shown, the fiber grating sensor includes a sensor housing 1, an upper cantilever beam 2, a lower cantilever beam 3, a sensing fiber grating 4, a reference fiber grating 5, a quality block 6, a fiber protection hole 7, a sealing cover 8, a screw 9, an optical fiber Protection tube 10, spring device 11;

[0017] Two cantilever beams with the same shape are fixed on one side of the housing 1 , and the fixed ends of the cantilever beams are connected with the housing 1 as a whole. The two cantilever beams are parallel to each other and have exactly the same shape, which is a combined shape of a rectangle and an isosceles triangle, and are made of exactly the same elastic material. Insert the free ends of the two cantilever beams into the mass block 6, and connect with the mass block 6 as a whole.

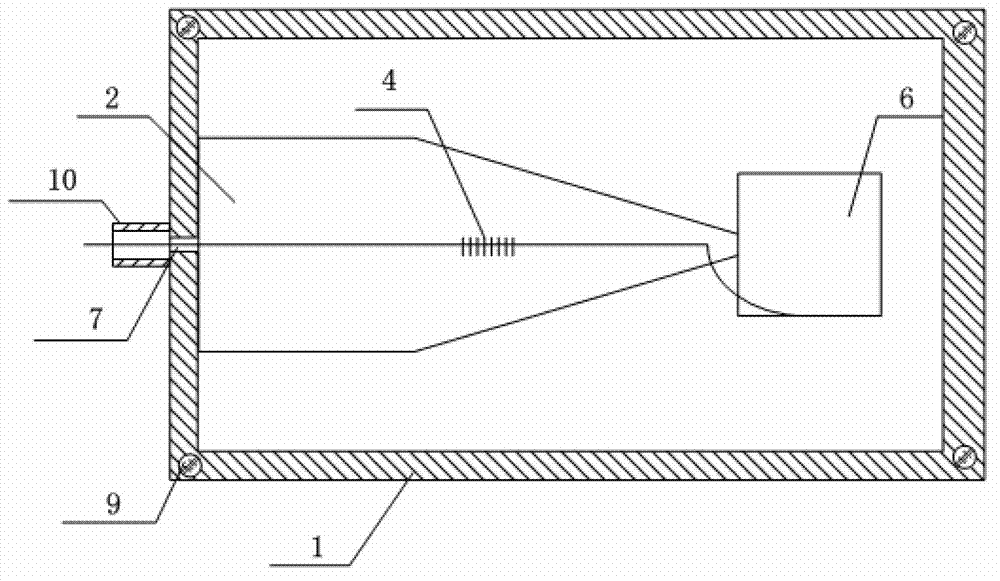

[0018] Such as figure 2 As shown, the apex of the isosceles triangle vertex in the combined shape of the cantilever beam is the free end of the cantilever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com