Double-cantilever beam type micro-mechanical acceleration sensor

An acceleration sensor and cantilever beam micro technology, which is applied in the direction of acceleration measurement using inertial force, can solve the problems of low sensitivity, mutual restriction of frequency and sensitivity, and high sensitivity, and achieves good repeatability, simple and symmetrical structure, and good thickness consistency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

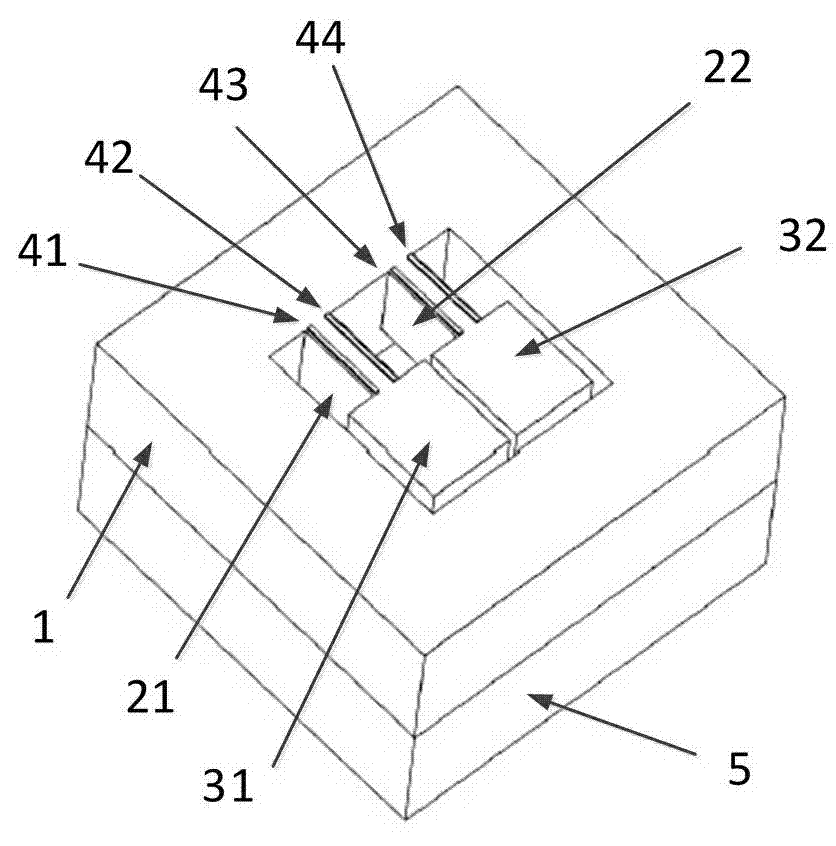

[0023] figure 1 It is a structural schematic diagram of the double cantilever beam type micromachined acceleration sensor of the present invention. exist figure 1 Among them, a kind of double cantilever beam type micromachined acceleration sensor of the present invention comprises a sensitive chip and a lower glass plate 5; wherein, the sensitive chip contains a frame 1, a first cantilever beam 21, a second cantilever beam 22, a first quality block 31, The second mass block 32, the first piezoresistor 41, the second piezoresistor 42, the third piezoresistor 43, and the fourth piezoresistor 44 are connected in such a way that two mutually independent The first cantilever beam 21 and the second cantilever beam 22, one end of the first cantilever beam 21 is connected with the frame 1, the other end is connected with the first mass block 31, one end of the second cantilever beam 22 is connected with the frame 1, and the other end is connected with the frame 1 The second mass blo...

Embodiment 2

[0029] The structure of this embodiment is the same as that of Embodiment 1, except that the thickness of the cantilever beam of the sensitive chip is 100 μm, the length is 130 μm, and the width is 40 μm; the thickness of the proof mass is 100 μm, the length is 120 μm, and the width is 120 μm. The natural frequency is 250kHz, and the sensitivity is about 0.1μV / g / V. The gap between the movable part of the sensitive chip and the glass plate is 200 μm.

[0030] The two mutually independent single-end fixed cantilever beams and mass blocks are placed in opposite directions, that is, the cantilever beams are arranged on opposite sides.

[0031] The present invention is by no means limited to the Examples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com