(111) single silicon wafer-integrated three-axis micromechanical acceleration sensor and manufacturing method

An acceleration sensor and acceleration sensing technology, applied in multi-dimensional acceleration measurement, acceleration measurement using inertial force, microstructure device composed of deformable components, etc., can solve the problems of difficult detection, complicated manufacturing process, high cost, etc. problems, to achieve the effects of reducing production costs, good process compatibility, and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

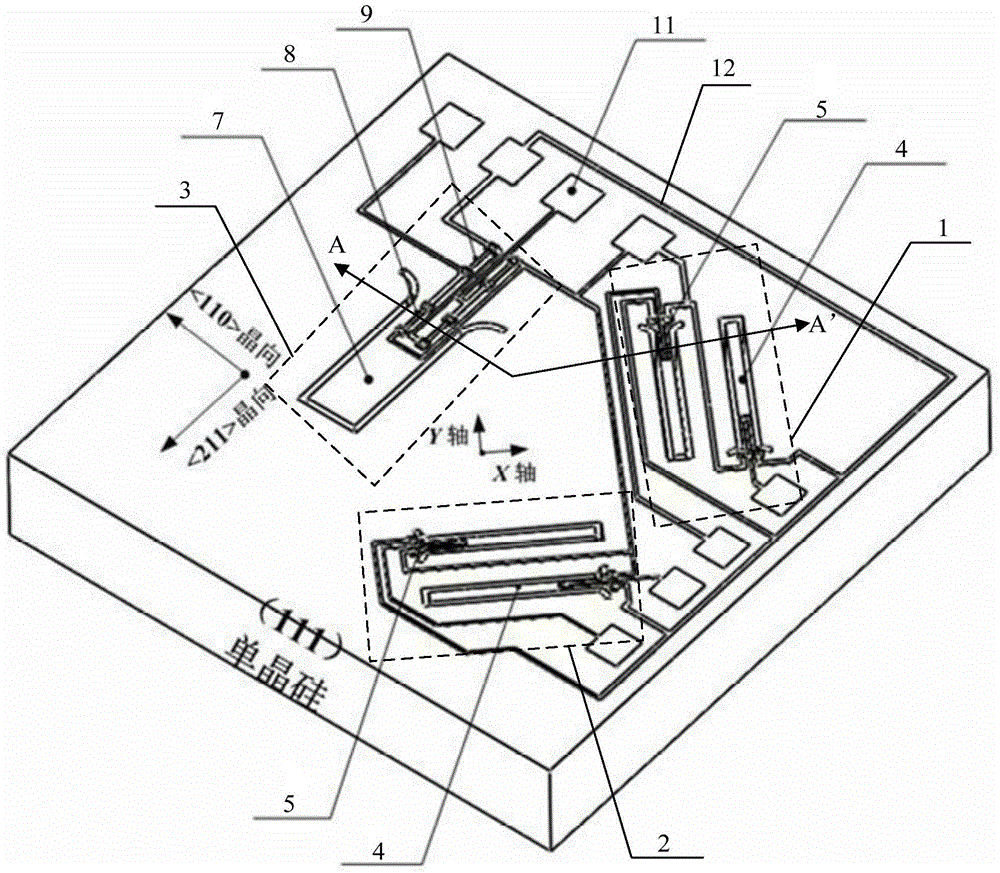

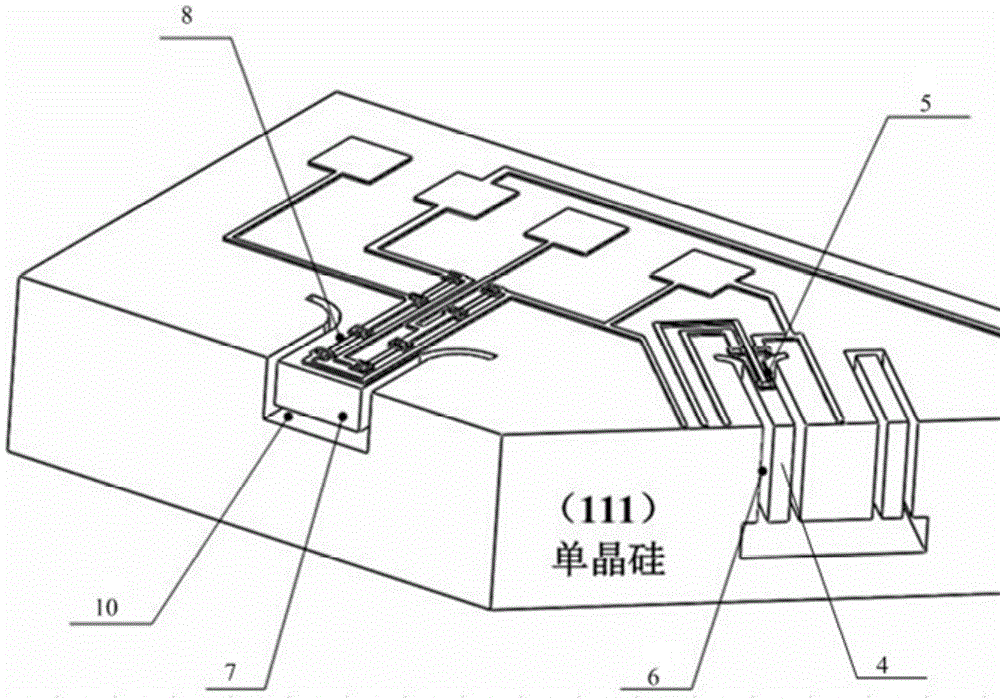

[0047] see figure 1 , the present invention provides a (111) three-axis micromachined acceleration sensor integrated with a single silicon chip, the (111) three-axis micromachined acceleration sensor integrated with a single silicon chip at least includes: (111) a single silicon chip and all integrated in Three mutually independent acceleration sensing units 1 in the X-axis direction, 2 acceleration sensing units 2 in the Y-axis direction and 3 acceleration sensing units 3 in the Z-axis direction on the (111) single silicon chip; The acceleration sensing unit 1, the acceleration sensing unit 2 in the Y-axis direction, and the acceleration sensing unit 3 in the Z-axis direction are integrated on the same surface of the (111) single silicon chip; wherein, the acceleration in the X-axis direction The sensing unit 1 has the same structure as the acceleration sensing unit 2 in the Y-axis direction, and both include a first cantilever beam 4 and a first pressure-sensitive resistor 5...

Embodiment 2

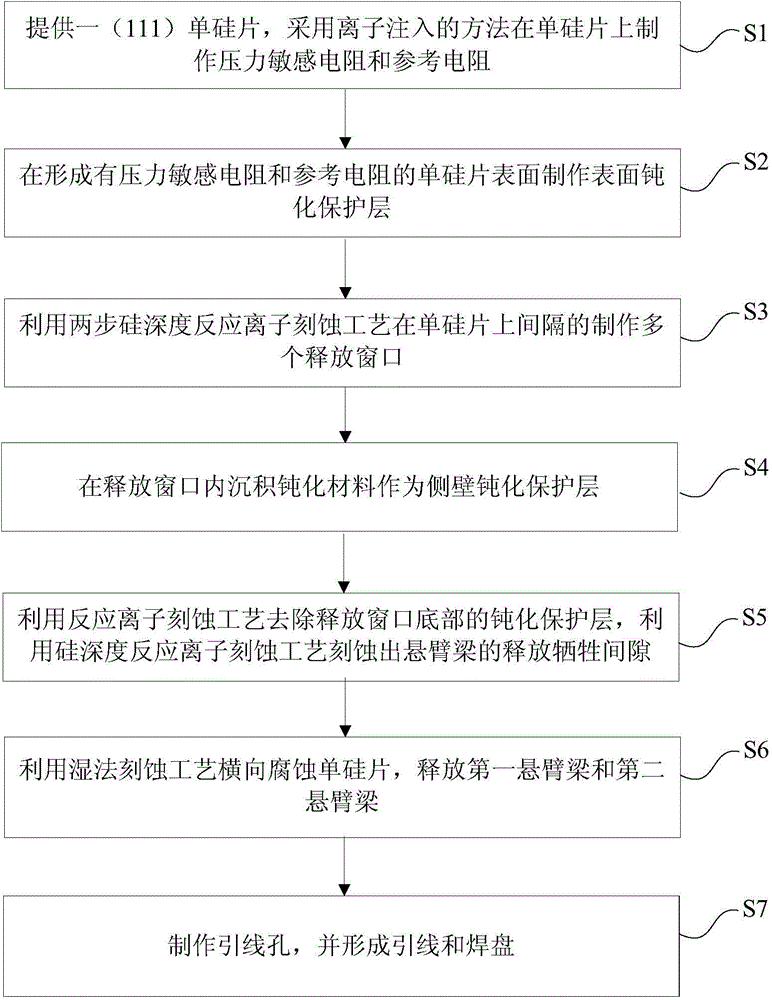

[0060] see Figure 3 to Figure 4 , the present invention also provides a (111) manufacturing method of a three-axis micromachined acceleration sensor integrated on a single silicon chip, comprising the following steps:

[0061] 1) An n-type (111) single silicon wafer is provided, the single-sided polished or double-sided polished silicon wafer, and the axis offcut is 0±0.1°; the method of boron ion implantation is used on the (111) single silicon wafer Make pressure-sensitive resistors and reference resistors on the front side, and the resistance value of the resistors is 2.0kΩ~3.0kΩ (such as Figure 4 (a) shown).

[0062] 2) Depositing low-stress silicon nitride and TEOS silicon oxide sequentially on the front side of the (111) single silicon wafer as a surface passivation protection layer by using LPCVD process.

[0063] 3) Using a two-step silicon deep reactive ion etching process to make a plurality of release windows at intervals on the (111) single silicon wafer, the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com