A predictive function control method for the speed of main drive system of roadheader

A technology of predictive function control and main drive, which is applied in the direction of adaptive control, general control system, control/adjustment system, etc., can solve the problems of anti-interference ability and control effect, cycle time-varying transmission error and other problems, and achieve improvement Dynamic output characteristics, ability to improve interference, and effect of improving anti-disturbance ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Taking the angular velocity control system of the cutter head of the hard rock roadheader as an example, the predictive function control method of the speed of the main drive system of the roadheader provided by the present invention is described in detail.

[0048] The symbols appearing in the drawings and some formulas and the physical quantities represented by the symbols are shown in Table 1:

[0049] Table 1

[0050]

[0051]

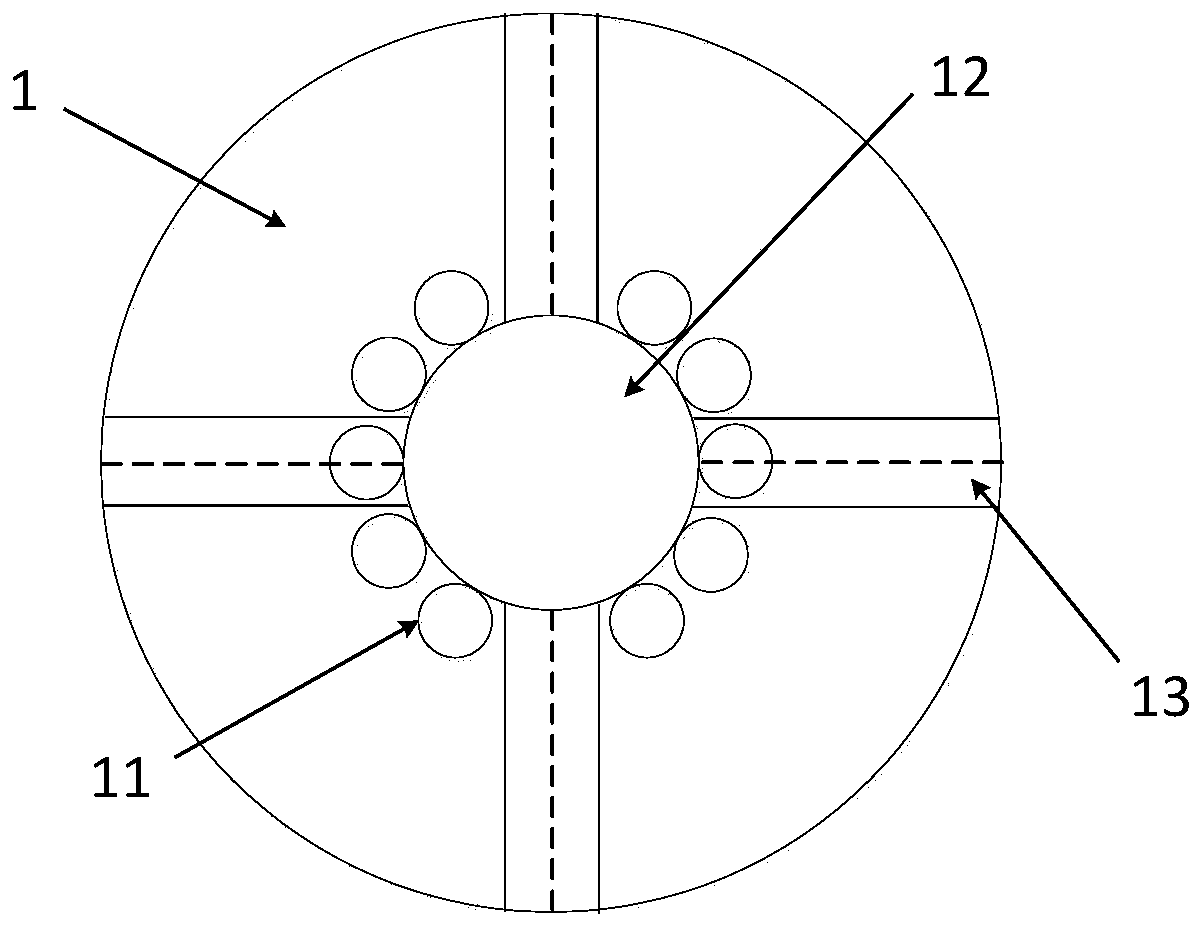

[0052] Such as figure 1 As shown, the hard rock boring machine cutterhead 1 includes a pinion 11 , a bull gear 12 and a spoke 13 .

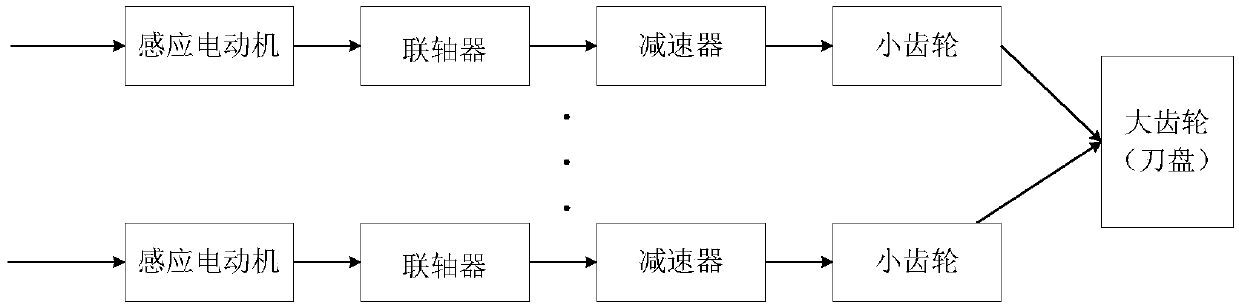

[0053] Such as figure 2 As shown, the hard rock roadheader cutter head drive system mainly includes induction motors, couplings, reducers, pinion gears, large gears and other mechanical components. Since the rotation of the large gear and the cutter head is synchronous, the angular velocity of the large gear is The angular velocity of the cutterhead.

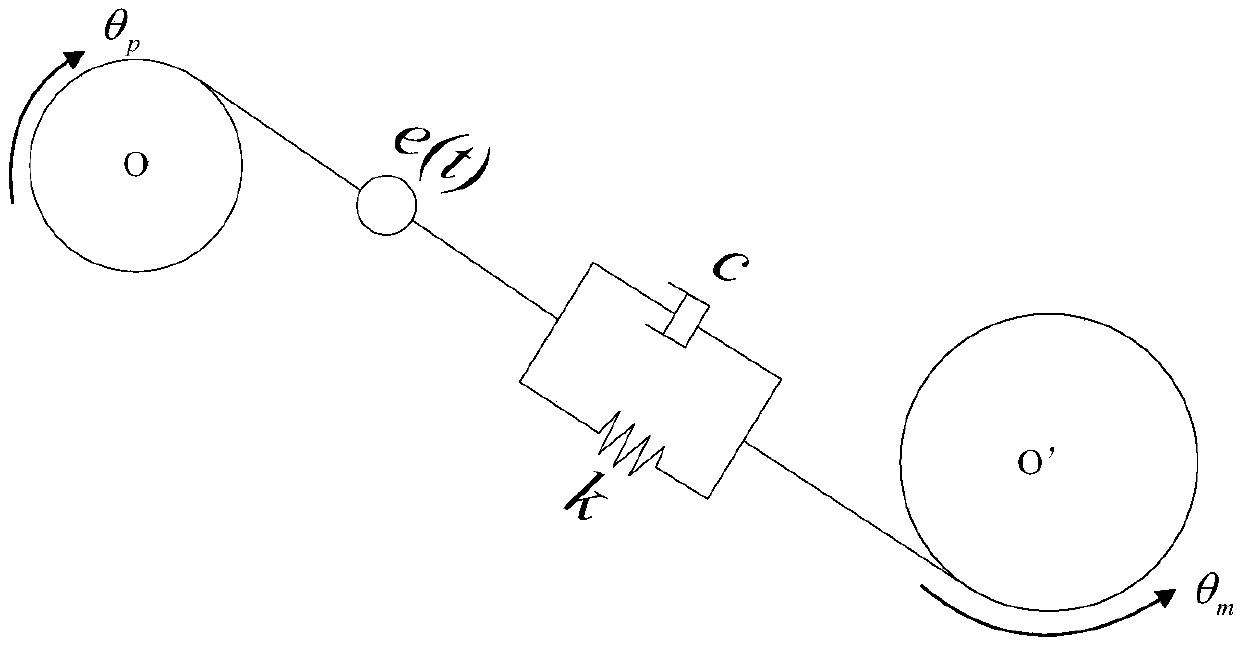

[0054] Such as image 3 As shown, the gear meshin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com