Double-cantilever differential fiber grating current transformer

A technology of current transformer and fiber grating, applied in the direction of measuring current, voltage/current isolation, measuring current/voltage, etc., can solve the problem that the detection accuracy is easily affected by the ambient temperature, and the detection accuracy of fiber grating current transformer is low in reliability. and other problems to achieve the effect of improving detection reliability and reducing impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

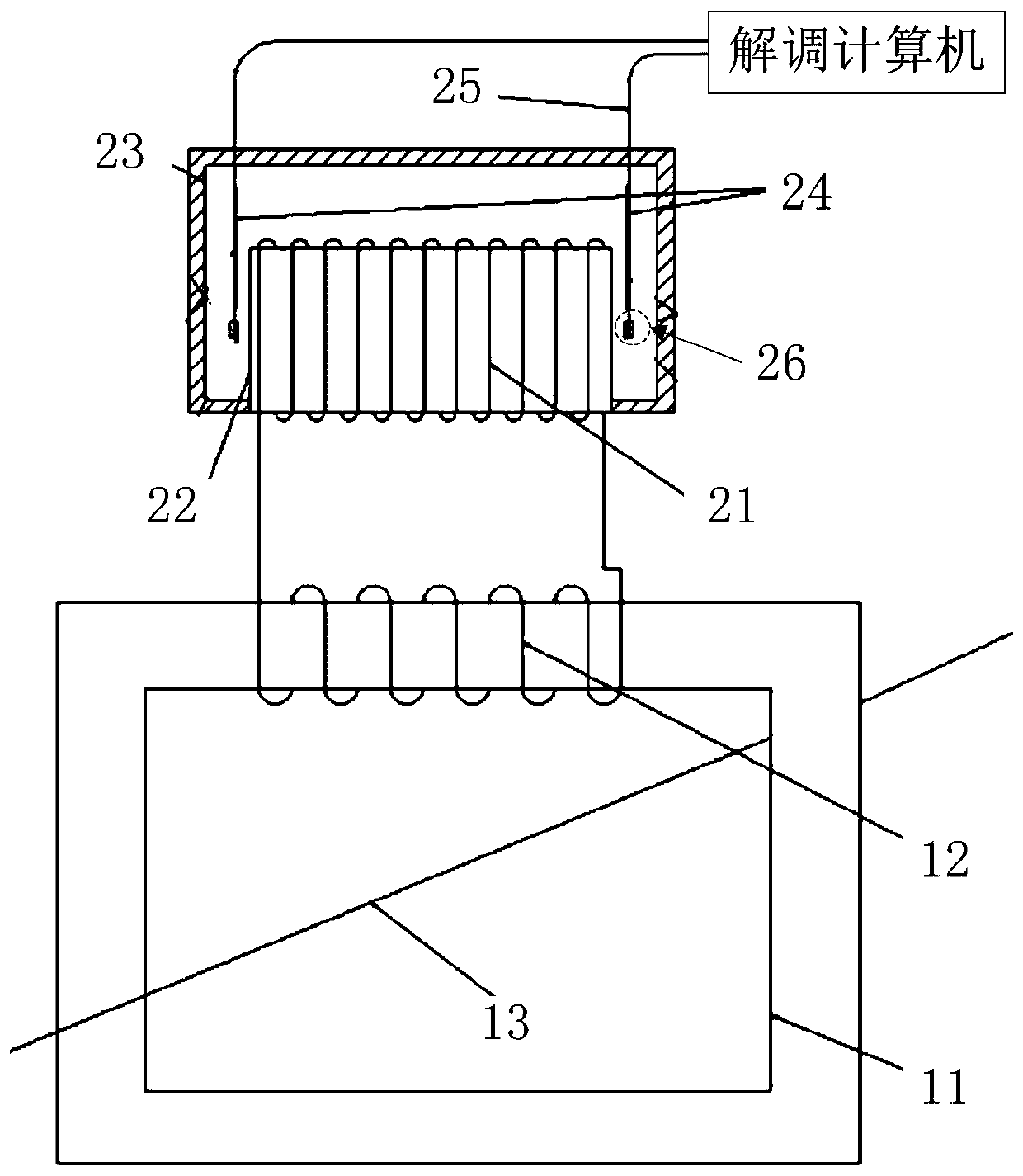

[0022] Such as figure 1 As shown, this embodiment provides a double cantilever beam differential fiber grating current transformer, the current transformer is suitable for cable sheath ground current detection, the current transformer includes: a first sensing unit, a second sensing unit and demodulation computer;

[0023] The first induction unit comprises a magnetizer 11 and a first induction coil 12, the magnetizer 11 is a hollow rectangle, and the first induction coil 12 is wound on a lateral side of the magnetizer 11; the second induction unit comprises a second induction coil 21, an iron The core 22 , the outer support structure 23 and two magnetic deformation units 24 , the second induction coil 21 is wound on the iron core 22 .

[0024] Further, the first induction coil 12 is wound on a lateral side of the magnetizer 11 in a clockwise direction, and the second induction coil 21 is wound on the iron core 22 in a counterclockwise direction; the magnetic field lines of t...

Embodiment 2

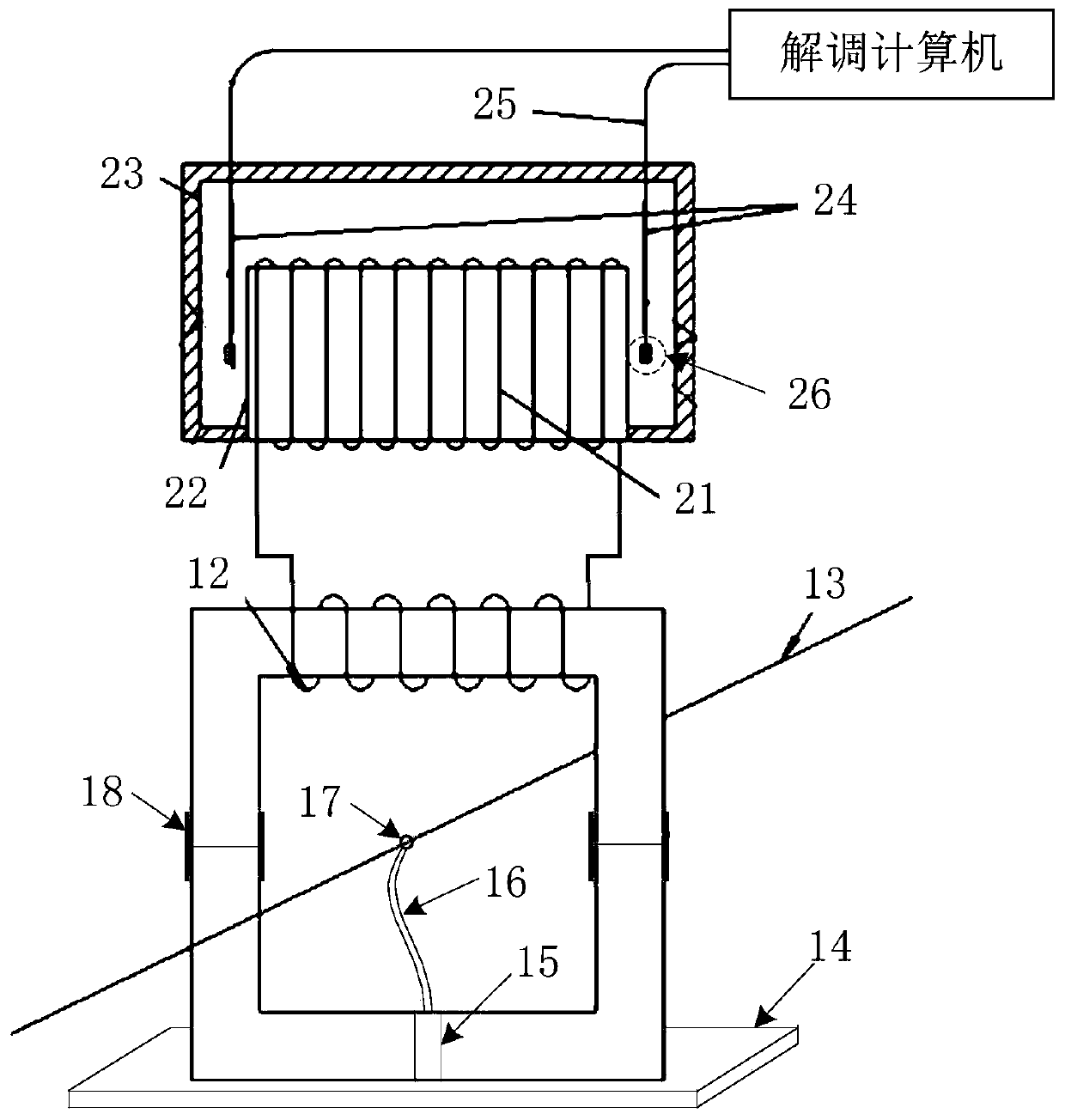

[0033] Such as figure 2 As shown, this embodiment provides another double-cantilever beam differential fiber grating current transformer. In order to further reduce the cost of current detection, the main detection part is set as a split structure, so that the same current carrying capacity When detecting the grounding current of the cable sheath of a different cable, the same set of current transformers can be used to avoid the difference between the detection devices, resulting in abnormal detection results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com