Suspended unbalanced dynamic tension sensor

A tension sensor and unbalanced technology, applied in the field of sensing, can solve the problems of complex installation and disassembly, uneven force transmission, cumbersome, etc., and achieve the effect of ensuring measurement stability, convenient disassembly and installation, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

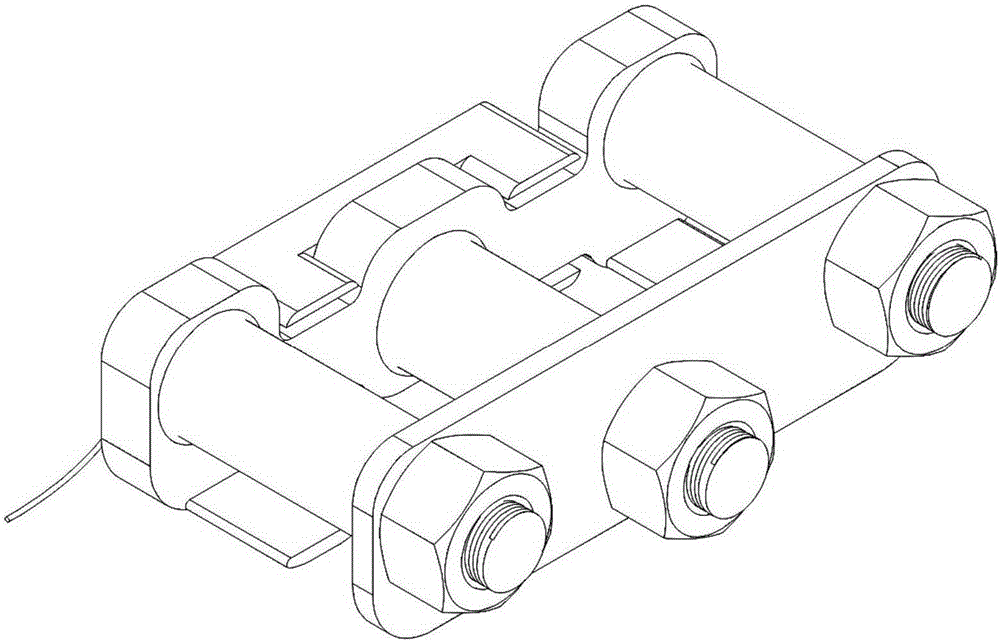

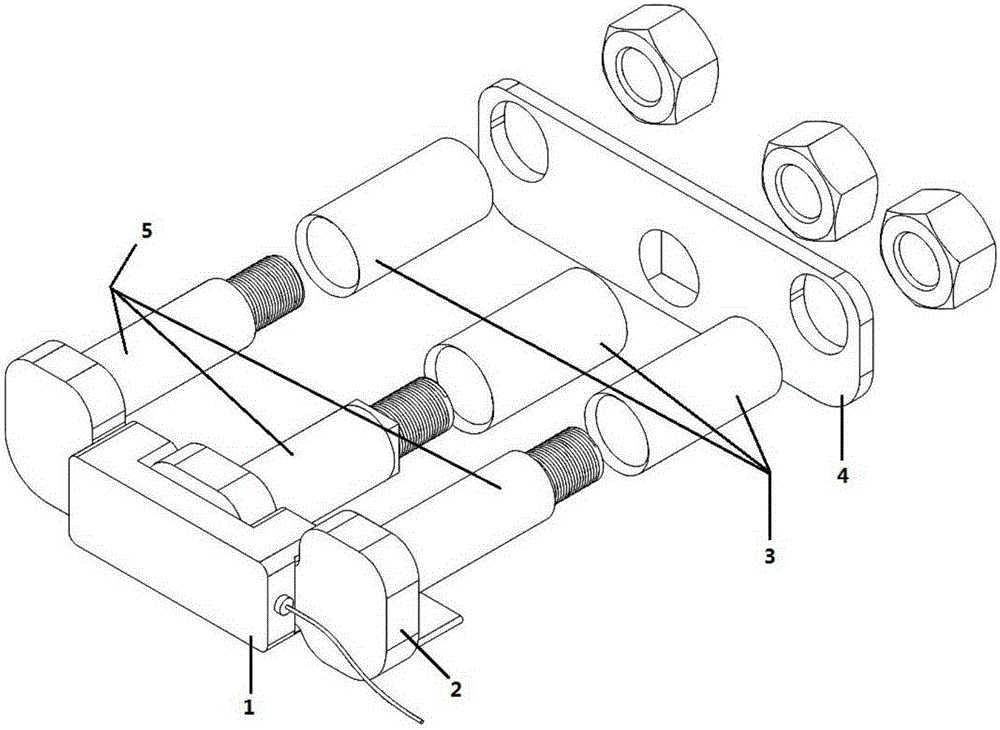

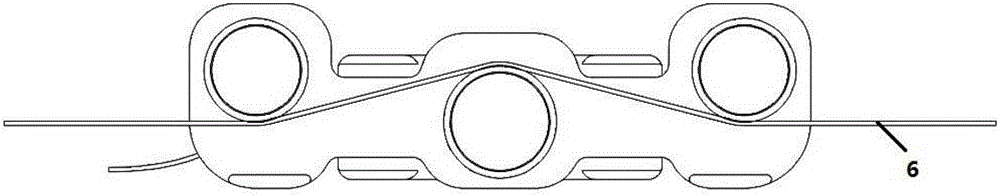

[0043] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0044] The invention discloses a suspension type unbalanced dynamic tension sensor, which comprises a three-axis force-bearing body, a baffle plate, first to third nuts, first to third rollers, first to fourth strain gauges, and a rope and electrical boxes;

[0045] The triaxial force-bearing body includes a force-bearing base plate and first to third force-conducting cylinders;

[0046]The first to third rollers are chamfering rollers;

[0047] The first force-guiding cylinder and the third force-guiding cylinder are vertically arranged at both ends of the force-bearing base plate, the second force-guiding cylinder is vertically set in the middle of the force-bearing base plate, and the first to third force-guiding cylinders Chamfers corresponding to the first to third rollers are respectively provided between the stressed bottom plate;

[0048...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com