A method and device for testing the stiffness of an anti-roll torsion bar for a rail vehicle

A technology of anti-rolling torsion bar and test device, which is applied in the direction of measuring device, elastic test, machine/structural component test, etc. It can solve the problems of fixed installation center distance, unknown torsion bar loading, and difficult movement of equipment, etc. , to achieve the effect of convenient maintenance and repair, reduced test cost, and short test time for a single piece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

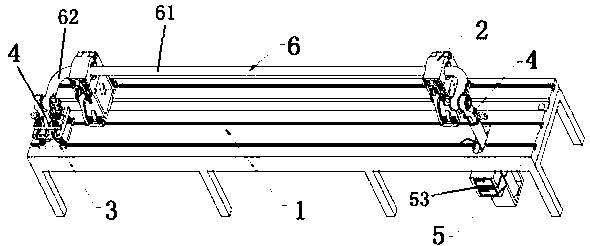

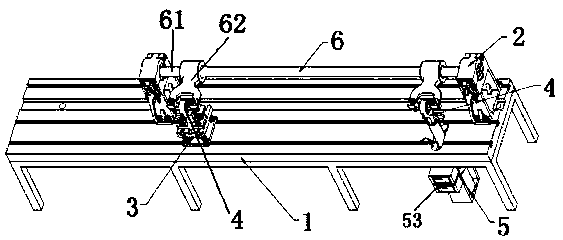

[0045] Such as Figure 1-Figure 10 As shown, a rail vehicle anti-rolling torsion bar stiffness test device includes a support module 1, a clamping module 2, a fixed module 3, a connecting module 4 and a load measurement module 5, wherein the clamping module 2 and the connecting module 4 are each There are two, the clamping module 2 and the fixing module 3 can be slidably arranged on the support module 1, the clamping module 2 is used to fix the torsion bar shaft 61, and a connecting module 4 is detachably connected above the fixing module 3 through one end , the other end is used to connect with the torsion arm 62 at the non-loading end, one end of the other connection module 4 is detachably connected with the loading measurement module 5, and the other end is used to connect with the torsion arm 62 at the loading end.

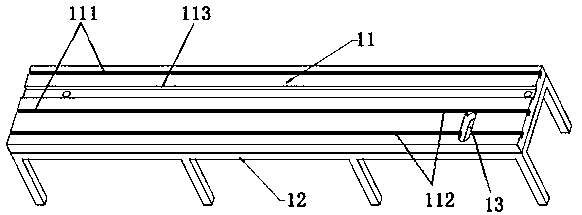

[0046] The support module 1 includes a bracket 12 and a base plate 11, the base plate 11 is arranged on the upper end of the bracket 12, the bracket 12 provid...

Embodiment 2

[0058] The difference between this embodiment and the first embodiment is that the cover plate 22 and the base 21 of the clamping module 2 are separated, and both ends of the cover plate 22 and the base 21 can be fixed by a locking device 23 . For example, two hasps are provided on the base 21 , and the cover plate 22 is loosened or fixed on the base 21 through the opening and closing of the two hasps.

Embodiment 3

[0060] The difference between this embodiment and the first embodiment is that the connection structure one 411 of the connecting rod 41 is a flat plate protruding downwards, and there is a pin hole for fixing with the fixed module 3 or the load measurement module 5 in the middle of the flat plate One 412, there is a pluggable quick latch 413 in the pin hole one 412.

[0061]The connecting structure three 331 of the connecting seat 33 is that there are two upwardly protruding flat plates in the middle of the connecting seat 11, and there is a pin hole three 332 for fixing with the connecting module 4 in the middle of the two flat plates, and between the two flat plates The distance is equal to the thickness of the flat plate where the connecting rod 41 protrudes downward.

[0062] The connection structure 2 521 of the loading connecting mandrel 52 is that there are two upwardly protruding flat plates above the loading connecting mandrel 52, and a pin hole 2 522 for fixing with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com