Squeeze film damper

A technology of extruding oil film damping and oil film, which is applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., can solve the problems that the rotor system affects the reliability of the whole machine, the high speed of micro rotating power machinery, etc., and achieves enhanced engineering Applicability, simple structure, and the effect of reducing fuel consumption loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

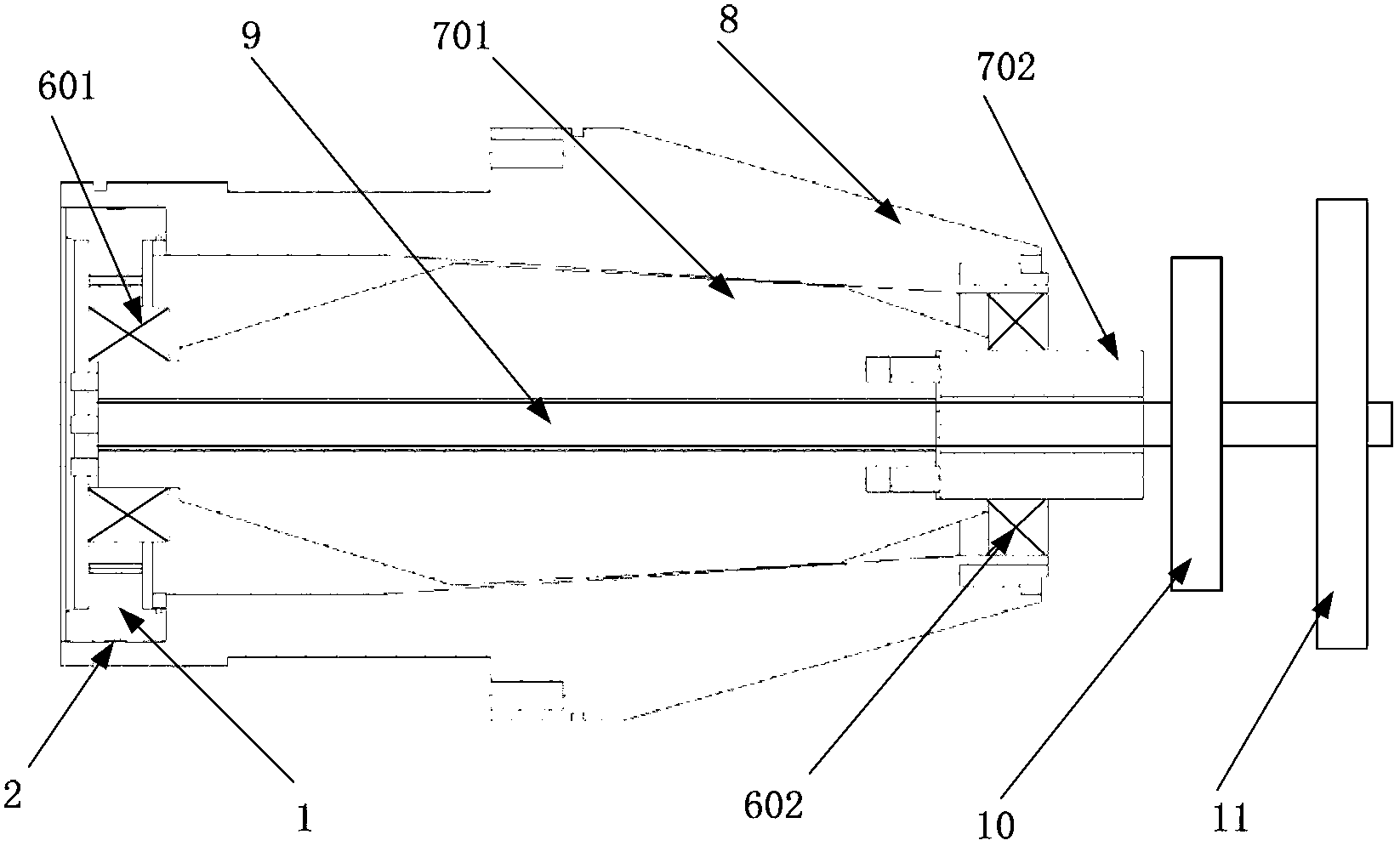

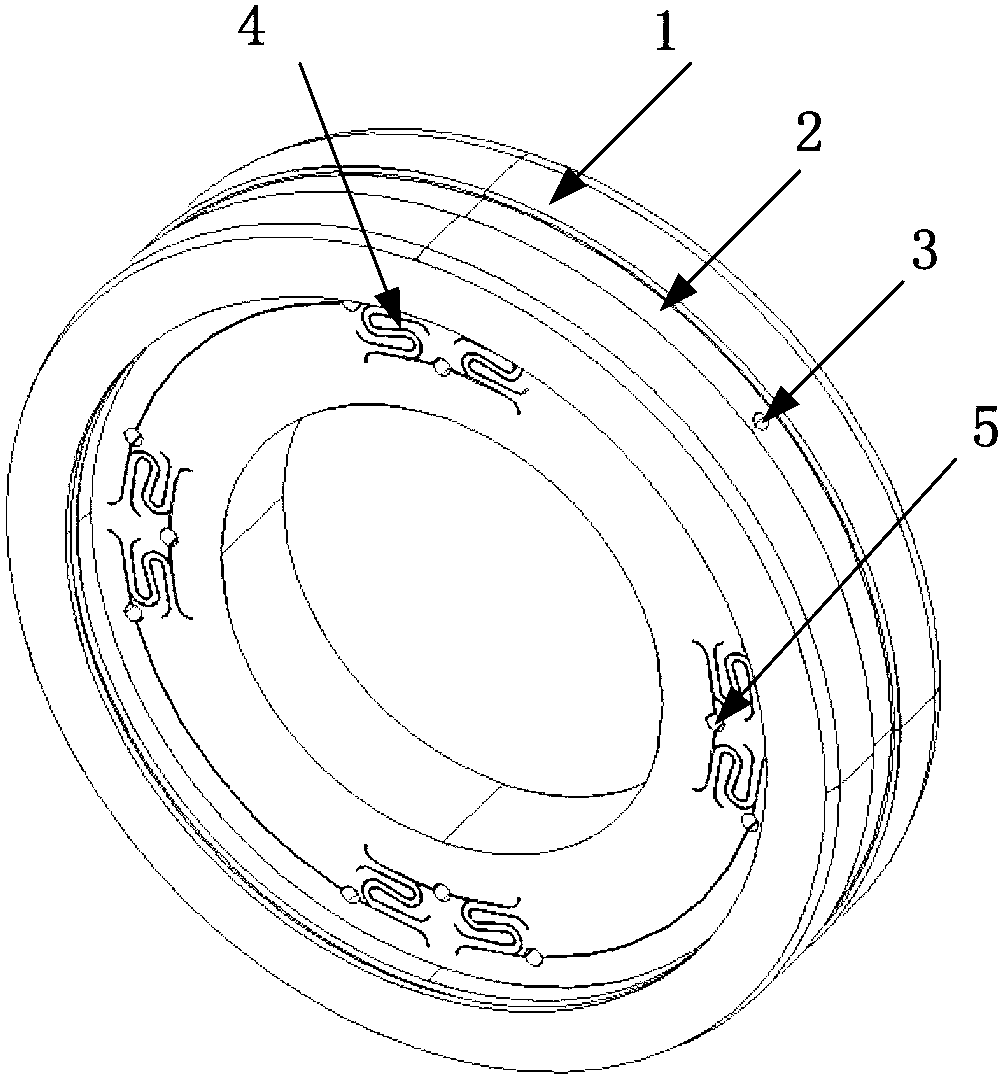

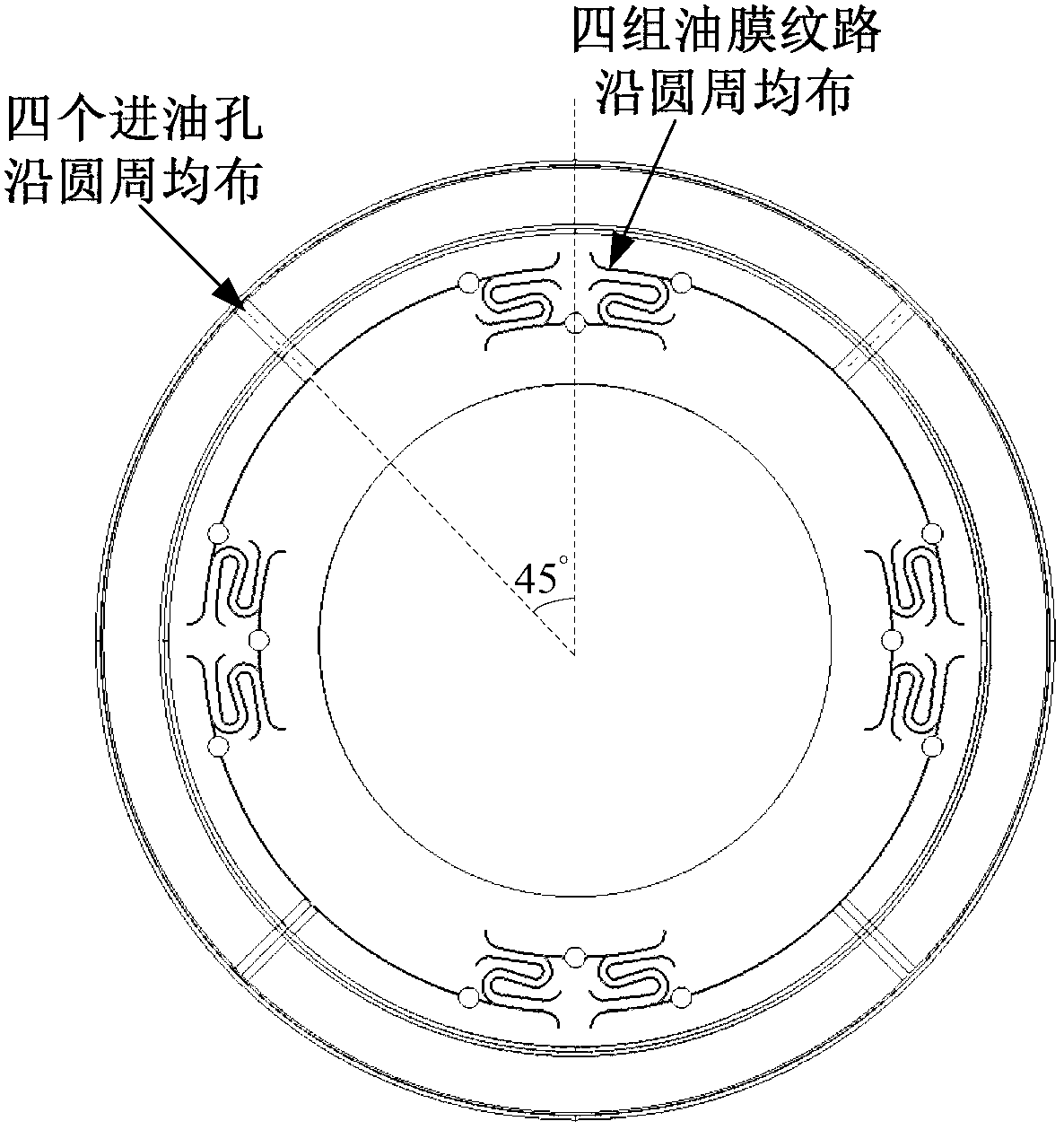

[0036] The invention provides a squeeze oil film damper, the squeeze oil film damper is installed on the 2-0-0 supporting rotor structure, such as figure 1 shown. Such as figure 2 , 3 As shown, the squeeze oil film damper 1 of the present invention has a T-shaped cross-section annular metal ring structure, and is installed between the left end bearing 601 and the housing 8 when in use, and the outer ring of the squeeze oil film damper 1 and the housing 8 are interference Fitting, the inner ring of the squeeze oil film damper 1 and the bearing 601 are interference fit; the structural details of the squeeze oil film damper 1 include the oil inlet groove 2, the oil inlet hole 3, the oil film pattern 4, and the oil storage hole 5.

[0037] The oil inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com