Pneumatic turbine driven double rotor test bench

A technology of aerodynamic turbines and test benches, which is used in engine testing, mechanical component testing, and machine/structural component testing. performance, ease of maintenance, and reduced complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

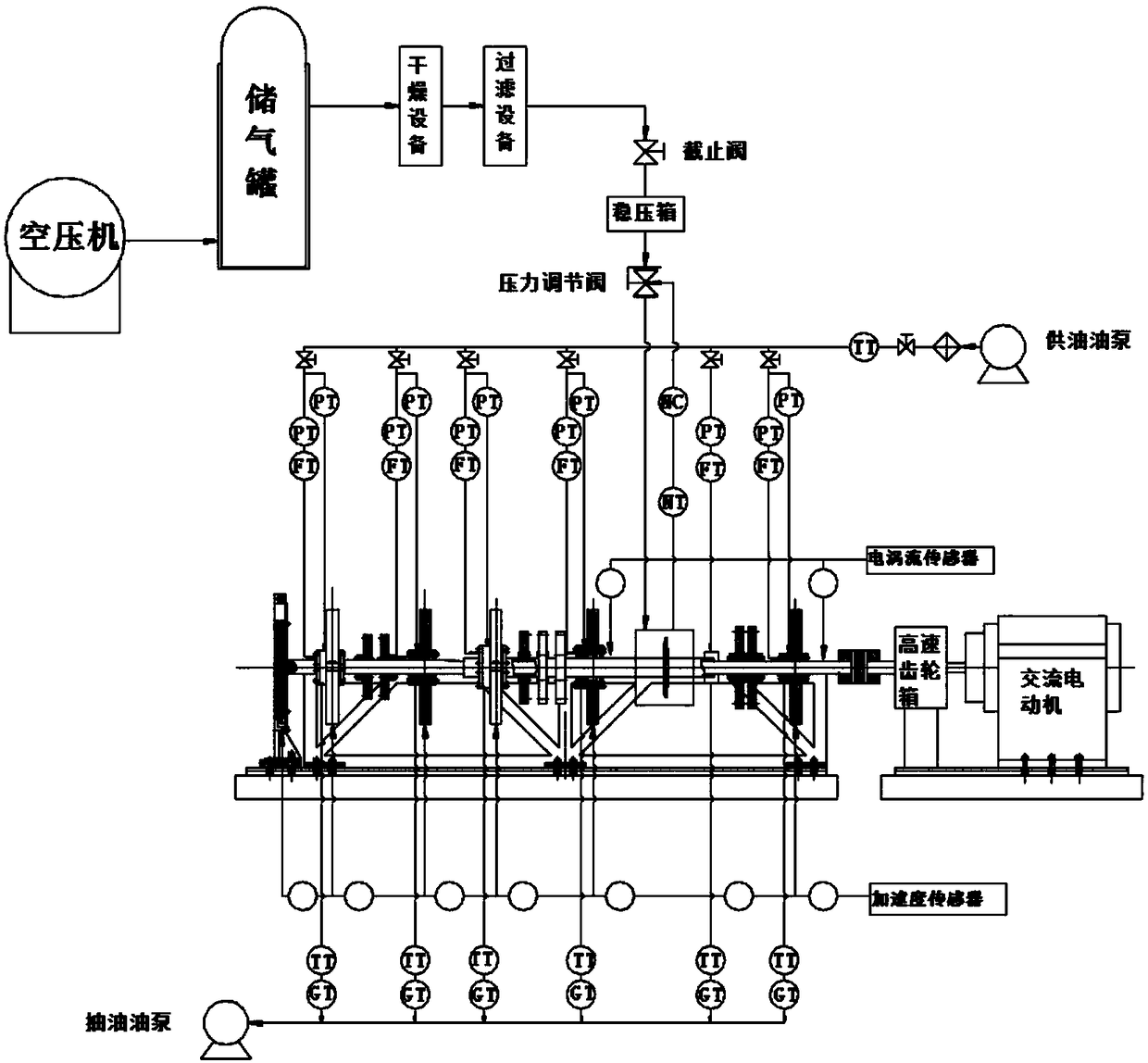

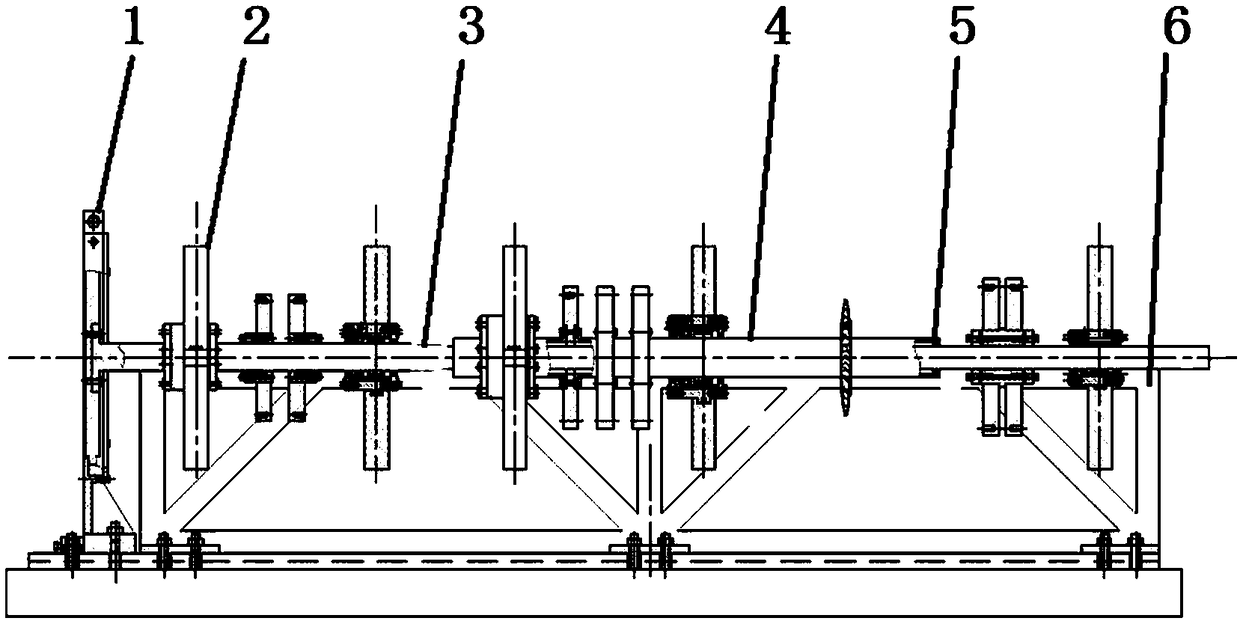

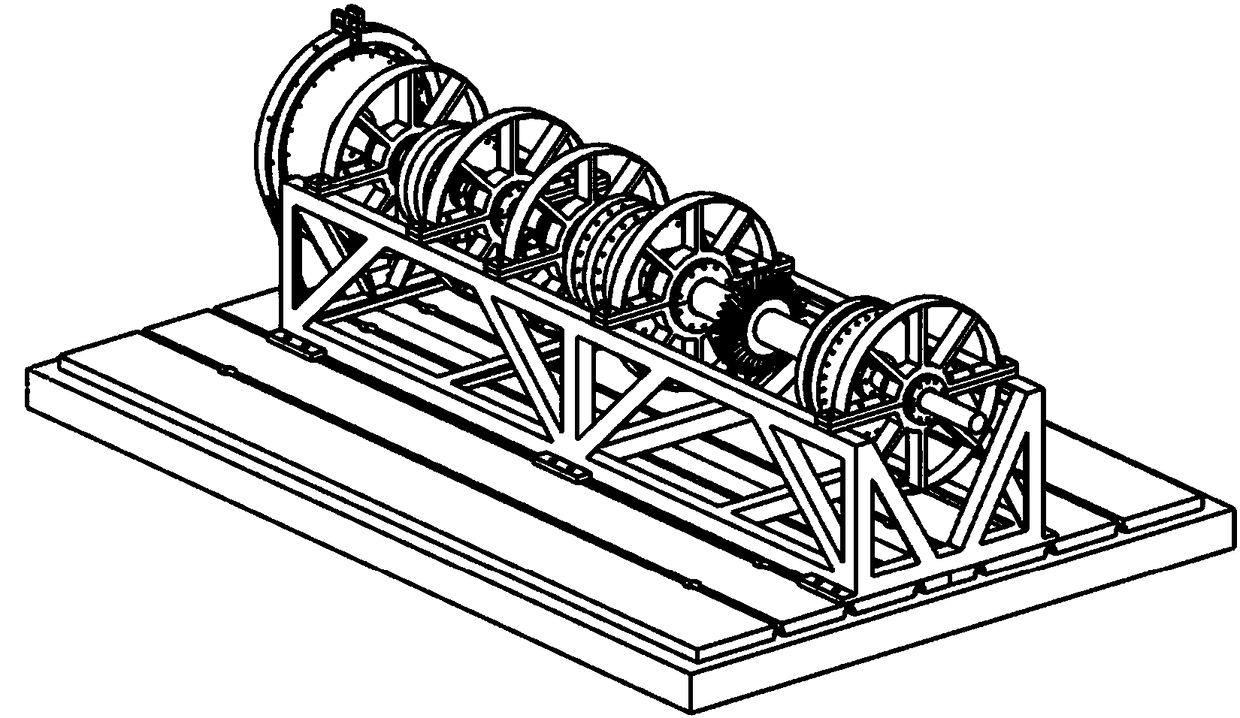

[0043] Operation of the present invention will be further described below in conjunction with accompanying drawing, content of the present invention comprises a complete set of pneumatic turbine type double-rotor test bench system:

[0044] as attached figure 1 , the inner rotor 3 drive system includes an AC motor and a high-speed gearbox, and the AC motor drives the inner rotor to rotate at high speed through the high-speed gearbox. A small inertia AC motor is selected to improve the response speed of the inner rotor speed control system, and the AC motor is controlled by an ABB frequency converter. The outer rotor 4 is driven by a pneumatic turbine. The driving system includes an air compressor unit and supporting pipelines, air filtration, drying treatment equipment and an air conditioning unit (valve group) for precise flow adjustment, which is driven by compressed air and installed on the outer rotor 4. The high-pressure pneumatic turbine 13 on the top controls and adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com