Dynamic pressure intelligent air bearing

A technology of air bearings and bearings, which is applied in the testing of measuring devices, instruments, and mechanical parts, and can solve the problems of small mechanical deformation and applying pre-pressure, so as to improve stiffness characteristics, stability, and signal detection accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific examples. However, it will be appreciated that the following specific embodiments are merely preferred embodiments of the invention, and is not to be construed as limiting the invention.

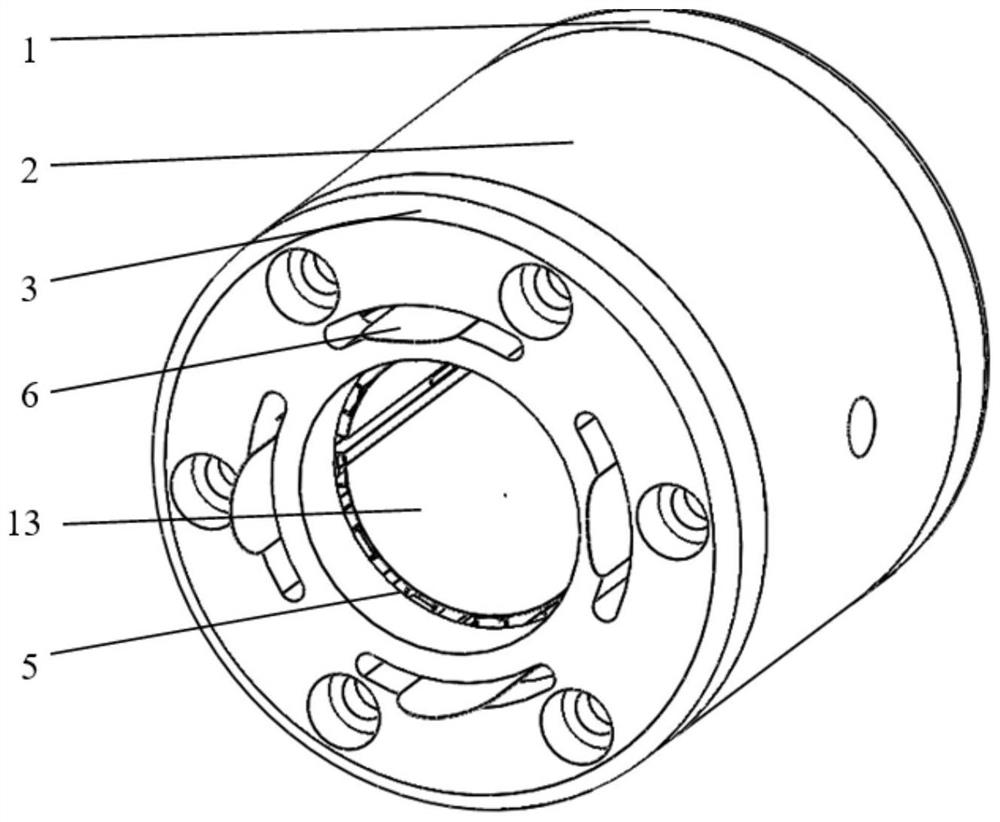

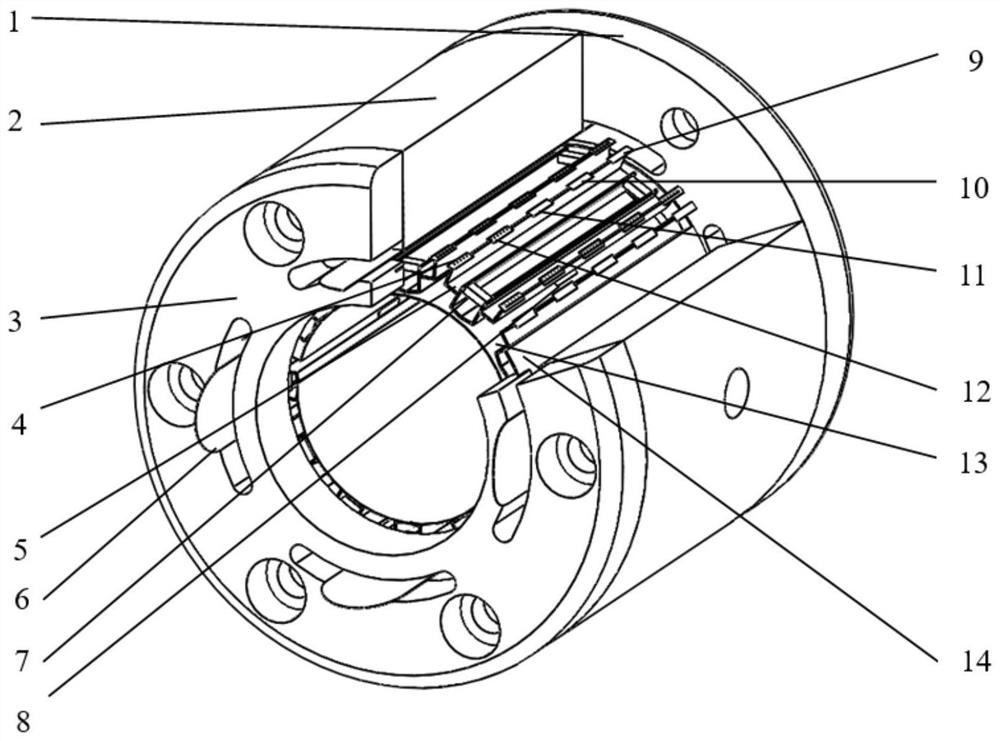

[0021] Such as figure 1 and figure 2 As shown, a dynamic intelligent air floating bearing includes: a bearing right end cap (1), a bearing sleeve (2), a bearing left end cap (3), pressure sensor (4) (9), a three-level amplifying mechanism (5), Sensor protective layer (6), PZT (7), temperature sensor (8), vibration sensor (10) (11) (12), a top foil (13), and a holder (14).

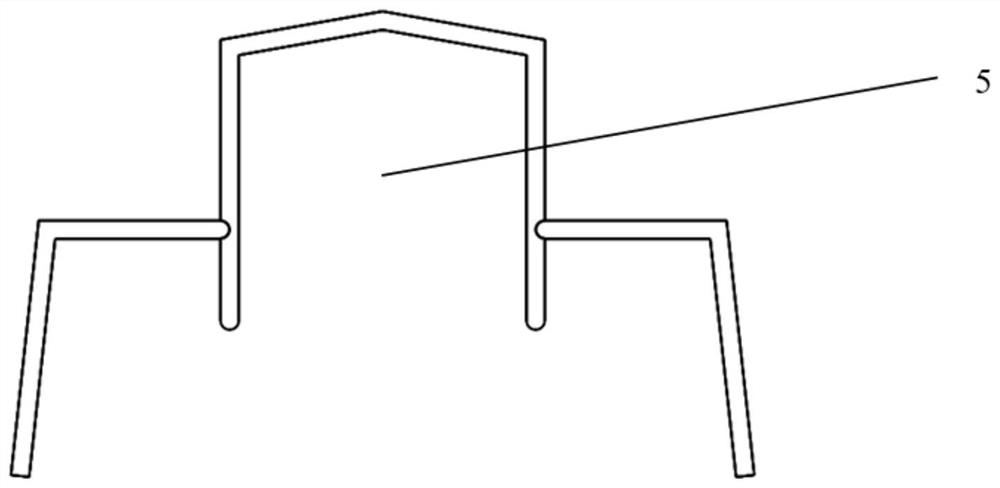

[0022] Such as Figure 4 As shown, the dynamic pressure air floating intelligent bearing is in operation, the vibration signal is performed by the first stage triangle amplification, the second stage lever amplification, the third stage triangle amplification transmission to the pressure sensor (4) (4) 9), th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com