Heat exchangers for refrigerant circuits

A technology of heat exchangers and refrigerants, applied in heat exchange equipment, refrigerators, refrigeration components, etc., can solve the problems of air-conditioning system output drop, heat exchange surface icing, reduction, etc., to increase efficiency, reduce fuel consumption, The effect of increasing the driving distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

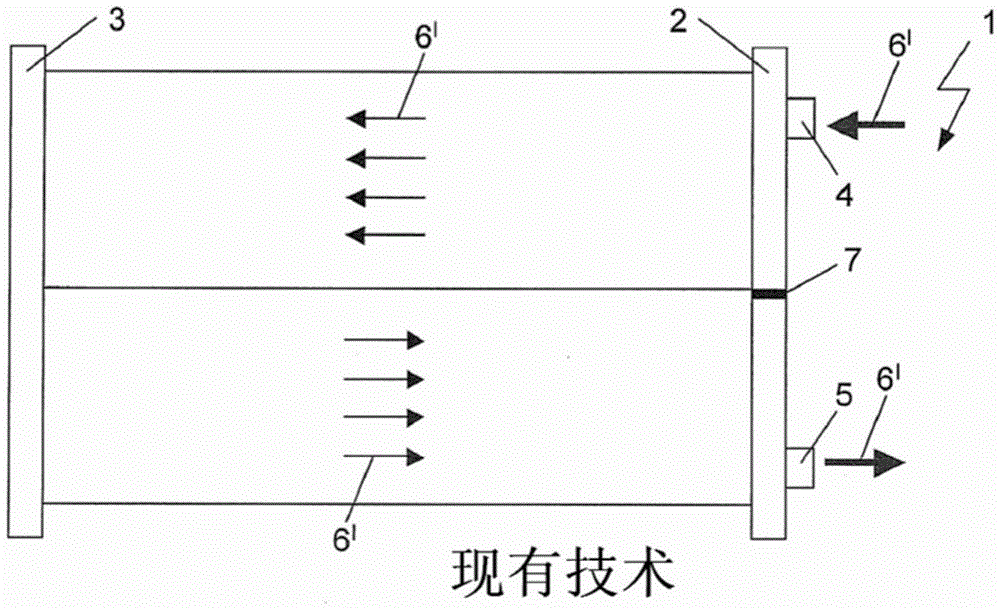

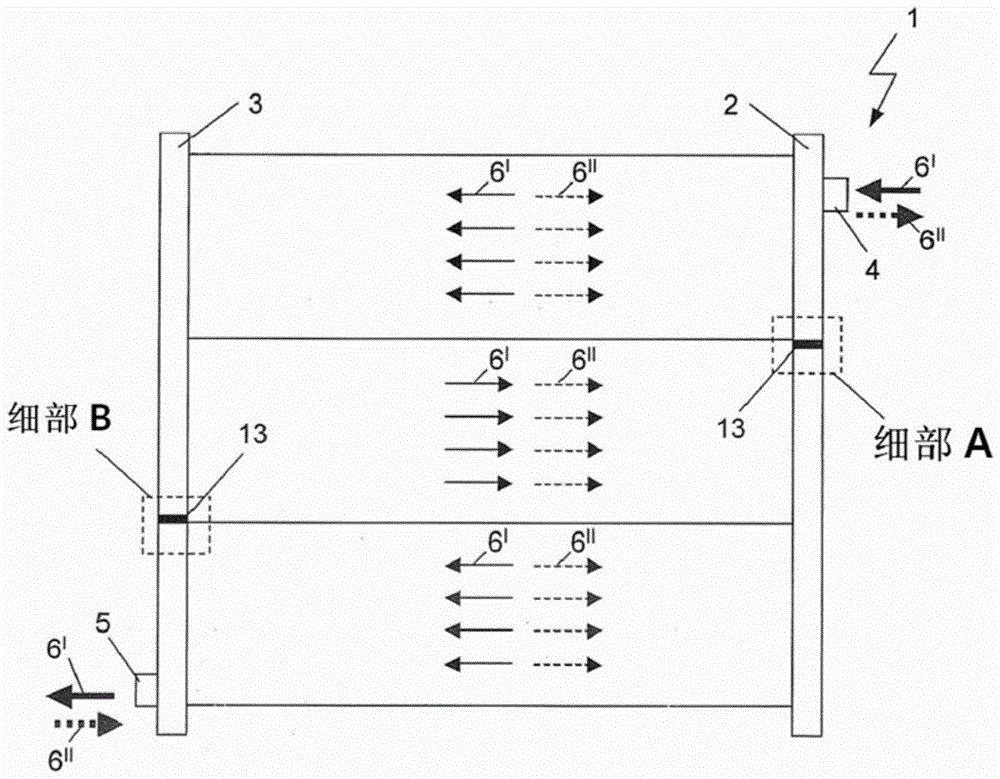

[0069] exist figure 1 In Fig. 1 , a heat exchanger 1 having a 2-pass configuration as a conventional condenser / gas cooler in cooling device mode is shown. However, the heat exchanger 1 is preferably a component of a refrigerant circuit of an automotive air-conditioning system (not shown).

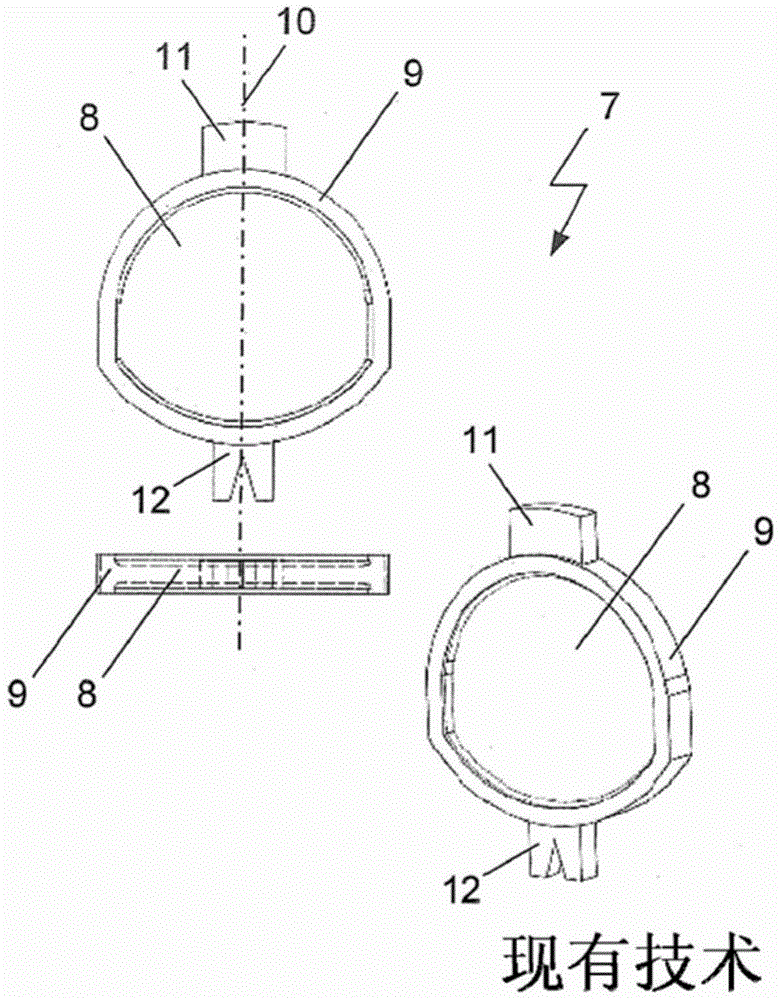

[0070] The gaseous refrigerant compressed by the refrigerant compressor flows into the first header 2 of the heat exchanger 1 through the first refrigerant inlet and outlet 4 due to its high temperature. The first header 2 comprises static separation elements 7 which divide the header 2 into mutually independent and mutually closed regions. Such static separating elements 7 are formed, for example, from sheet metal.

[0071] In the upper region, the gaseous refrigerant introduced into the first header 2 is evenly distributed to the plurality of flow paths of the first channel. Flow paths are identified with solid arrows. The refrigerant flows from the first header 2 to the second header...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com