Detection device and detection method for cross-hatch angle measurement of cylinder hole of cylinder body

A technology of angle measurement and cylinder block, applied in the direction of angle/taper measurement, etc., can solve the problems of high cost, complex measurement method, long measurement time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

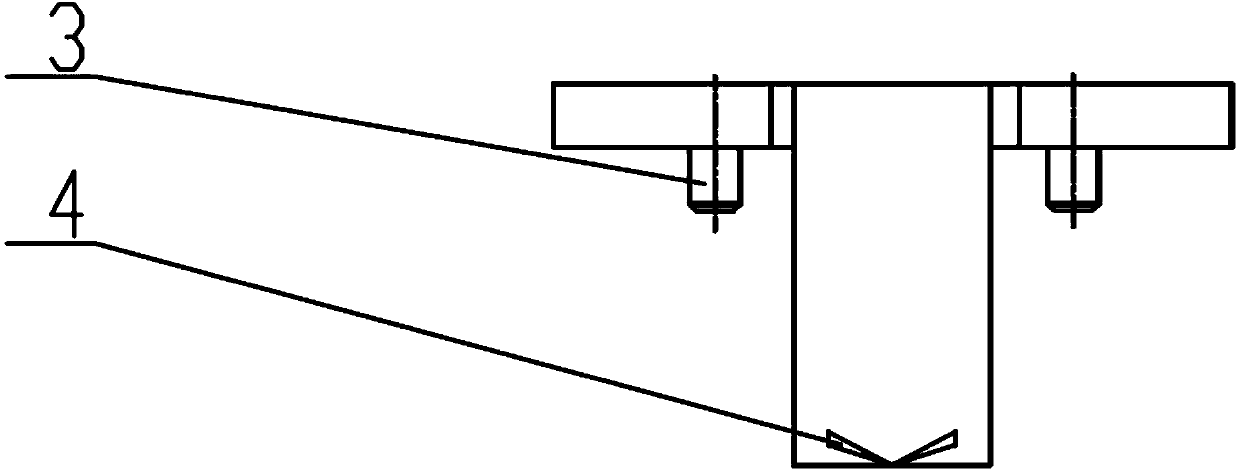

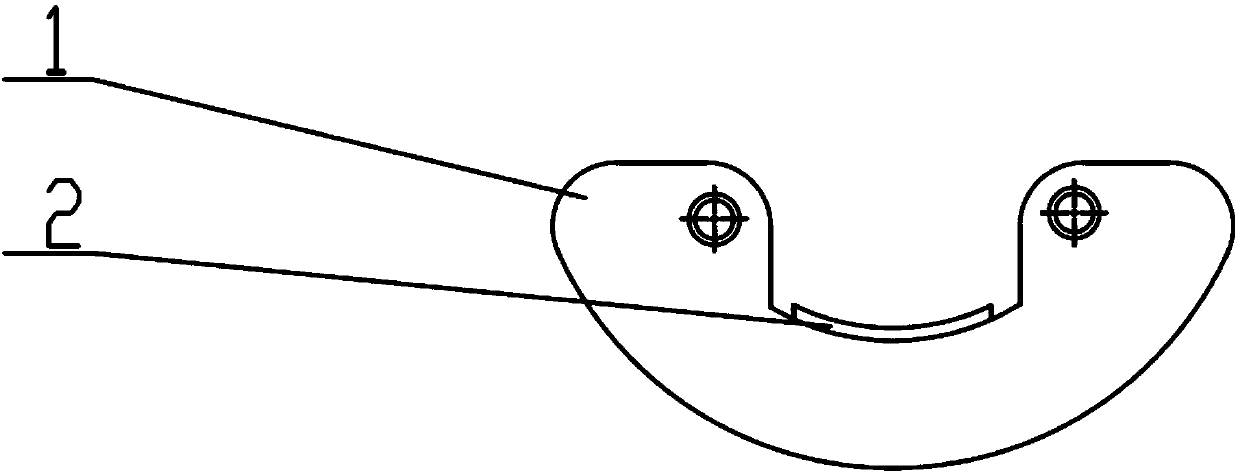

[0024] In the first embodiment, if figure 1 and figure 2 As shown, the present invention discloses a cylinder bore mesh angle measuring and checking tool, including a bottom plate 1, two positioning pins 3 installed on the bottom plate 1 and a transparent diaphragm 2, the bottom surface of the bottom plate 1 is horizontally arranged, and the bottom plate 1 Including the middle plate and ear plates on both sides of the middle plate for installing two sets of positioning pins 3 respectively, the inner contour curve of the middle plate is set corresponding to the cylinder hole contour curve, the transparent diaphragm 3 is set on the inner side of the middle plate, and the transparent diaphragm 2 A qualified area 4 for comparison is provided on the top, and two positioning pins 3 are arranged tangentially to the outer circle of the transparent me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com