Ultra-wide-angle industrial endoscope applied to float glass tin bath

A float glass, ultra-wide-angle technology, applied to color TV parts, TV system parts, TVs, etc., can solve problems affecting glass forming quality, tin bath temperature changes, tin dust drop, etc., to eliminate Effects of monitoring blind spots, reducing heat loss, and reducing cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

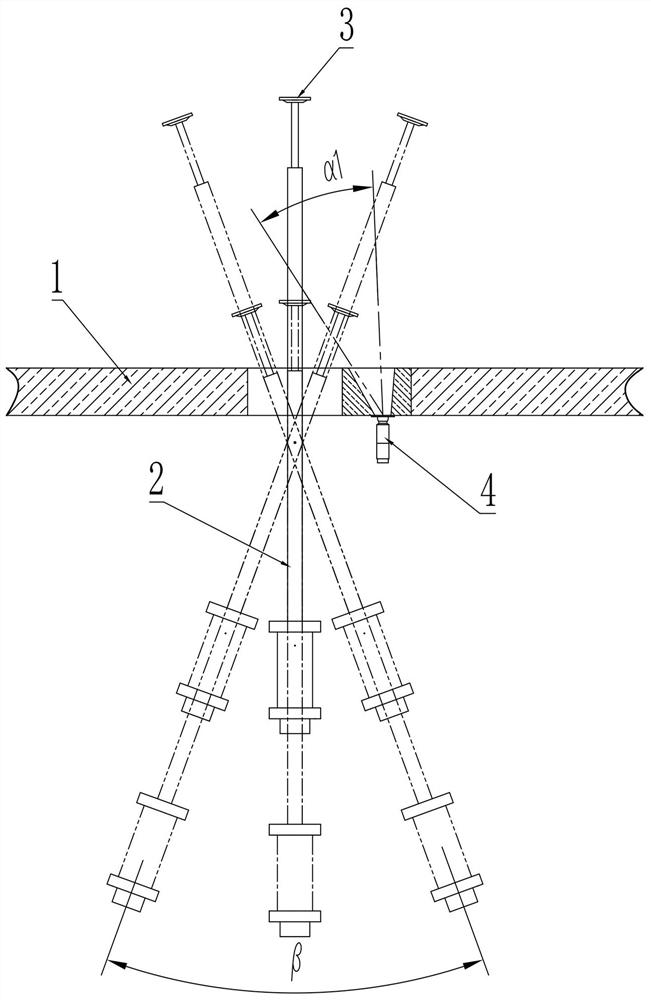

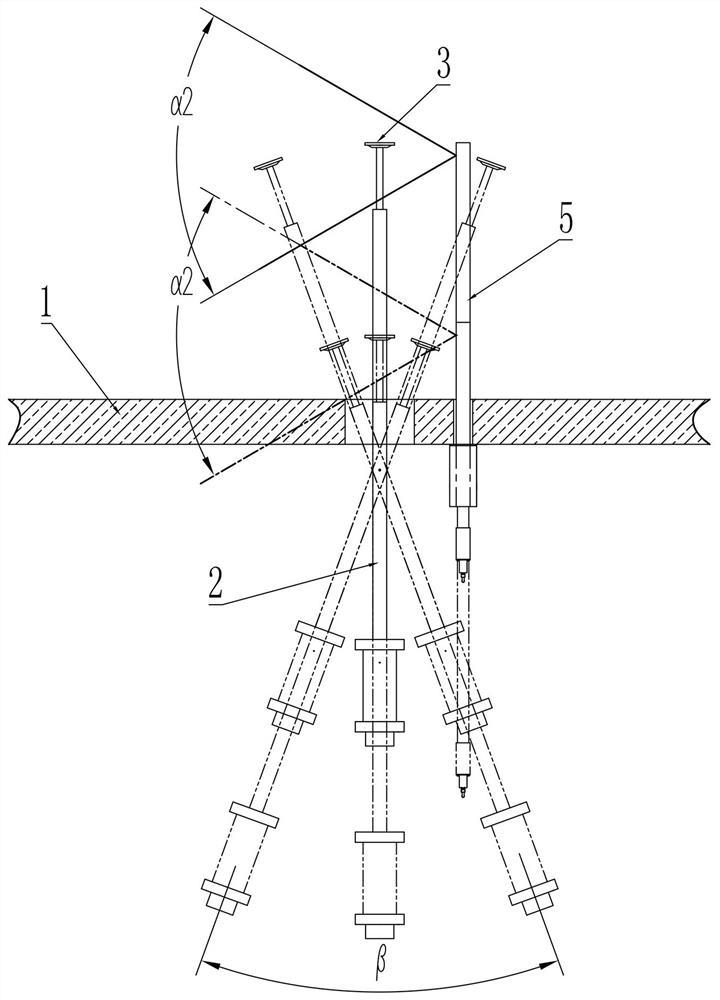

[0038] Embodiment An ultra-wide-angle industrial endoscope applied to a float glass tin bath

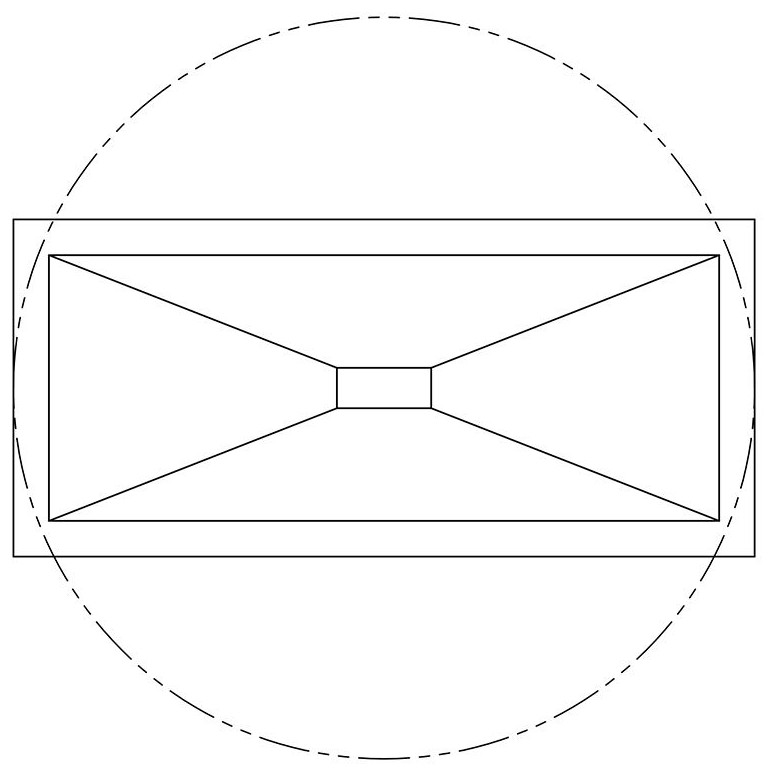

[0039] Such as Figure 4 As shown, the present embodiment is a short endoscope 6 with a certain inclination angle on the front end surface. After installation, the front end only extends into the inside of the tin bath by about 10 cm, and innovatively adopts a quadrangular truss-shaped observation hole 7 and a camera 13 to rotate and scan. In this way, the horizontal viewing angle of this embodiment is Φ≥110°, so that the two edge pulling machines 2 can be monitored in all directions without any dead angle.

[0040] Specifically, this embodiment includes a protective cover 8 with an observation hole 7 at the front end and a peeping mechanism inside the protective cover 8 . Wherein, the protective cover 8 is an air-water cooling protective cover, which can ensure that the peeping mechanism is not damaged by high temperature through two modes of air cooling and water cooling. Such as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com