Preparation method of aluminum alloy surface silanization conversion film

A technology of aluminum alloy surface and silanization, applied in the direction of metal material coating process, etc., can solve the problems of high pollution, personal injury of construction personnel and personnel in the machine, and achieve the effect of good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

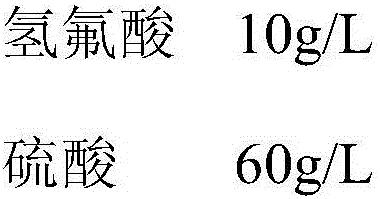

[0019] A method for preparing a silanized conversion film on the surface of an aluminum alloy, the steps of which are as follows:

[0020] (1) Pre-processing:

[0021] (1.1) Grinding: Polish the aluminum alloy surface with 400# sandpaper, wash it with deionized water, dry it, and set it aside;

[0022] (1.2) Alkali washing: Alkali washing is carried out with alkaline washing liquid to completely remove the oxide film on the surface of the aluminum alloy, revealing a pure metal matrix, and providing a good foundation for the subsequent chemical film formation;

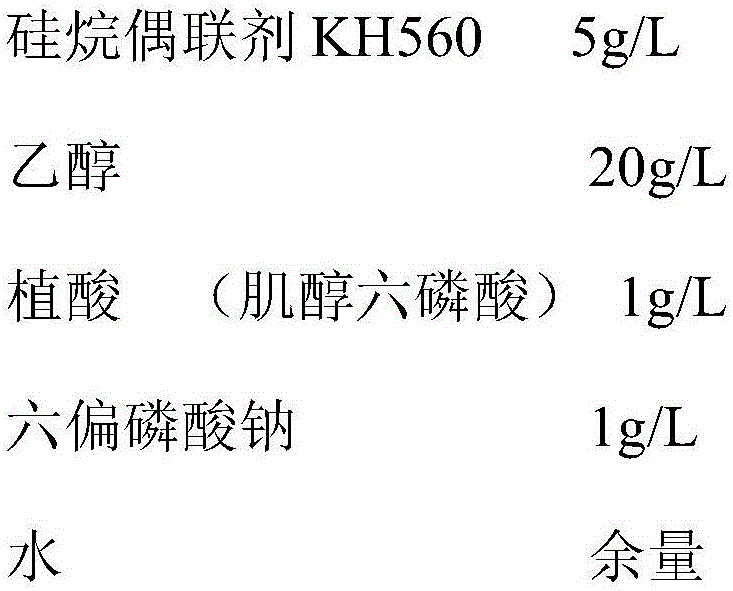

[0023] The composition of alkaline washing solution is as follows:

[0024]

[0025] The alkali washing condition is normal temperature, and the time is 3 minutes.

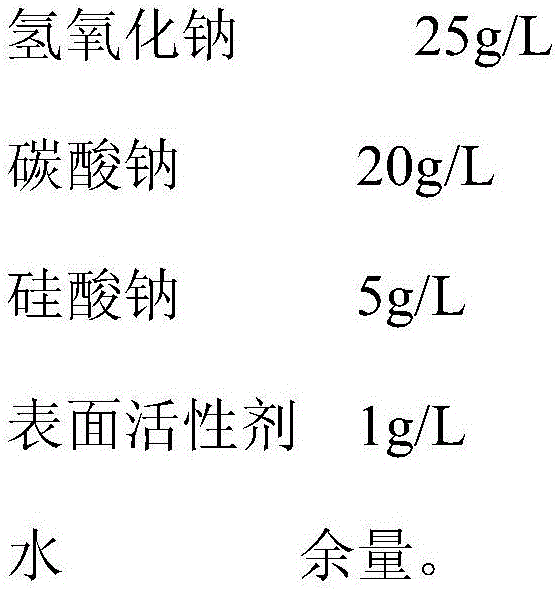

[0026] (1.3) Pickling: After the aluminum alloy material is alkali-washed, a layer of taupe or gray-black hanging ash will adhere to the surface, which is mainly composed of intermetallic compounds such as copper, iron, silicon, etc. that are insoluble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com