Three-dimensional detection method of plateau honing cross hatches in inner hole of cylinder liner

A detection method and technology for honing texture, which can be used in measuring devices, instruments, optical devices, etc., to solve problems such as the inability to meet the diverse requirements of customers, the many technical requirements for platform honing texture, and the limitation of industry exchanges and development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] 1. Research on three-dimensional surface roughness parameters and their application rules. Through a large number of comparative tests and research on typical parts and typical surface structures, according to the use requirements and geometric structure characteristics of the surface of special industries or special structures, formulate functional parameter sets, and do preliminary theoretical work on the promotion of product-oriented roughness standards .

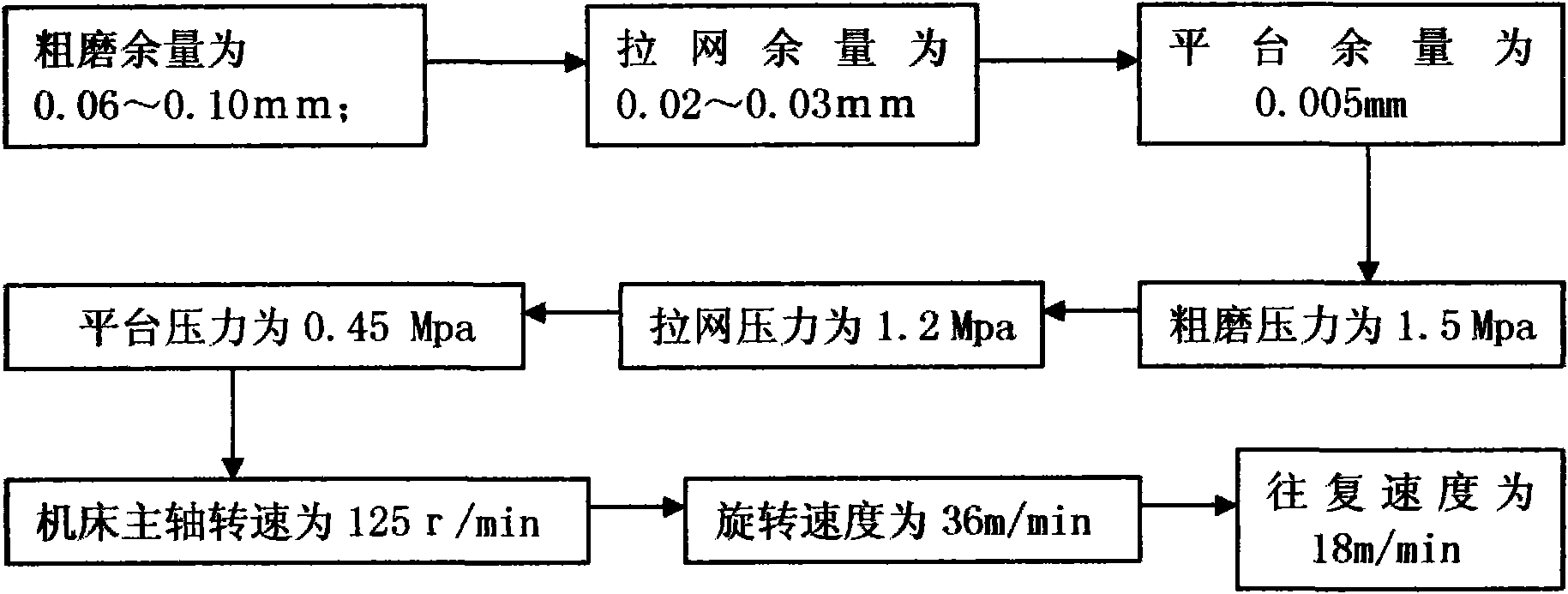

[0009] 2. Research on platform honing anilox process.

[0010] 3. Analyze the technical requirements of the current platform honing texture and find out its shortcomings.

[0011] 4. Propose the technical specifications and detection methods for the honing texture of the inner hole platform of the internal combustion engine cylinder liner based on 3D.

[0012] 5. Help enterprises establish and improve enterprise and industry technical specifications, enrich and improve traditional roughness theory.

[0013] 6. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com