Connection rod and production process and dedicated device for processing half-product of connection rod

A special device and production process technology, applied in the direction of furniture connection, connection components, mechanical equipment, etc., can solve the problems of low production efficiency, high cost, large product size, etc., achieve material saving, high production efficiency, and improve processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

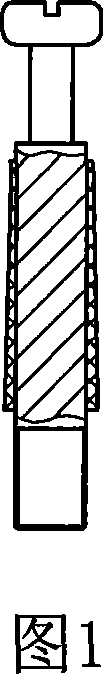

[0029] As shown in Figure 4, the specific embodiment of the present invention is a connecting rod for furniture. The connecting rod includes a thin rod 52 and a plastic-coated body 7. A screw groove is arranged on the head 51 end surface of the upper end of the thin rod 52. The screw-in end 6 of 52 forms an external thread, and the overmolding body 7 is wrapped on the outside of the rod wall of the thin rod 52, and a reticulate pattern 8 is formed on the rod wall of the thin rod 52 where the overmolding body 7 is located, and the screwing of the thin rod 52 The end 6 forms a stepped shaft composed of a transition portion 54 and a core rod 53 , the diameter of the stepped shaft decreases from outside to inside, and the external thread 9 is arranged on the outer wall of the core rod 53 .

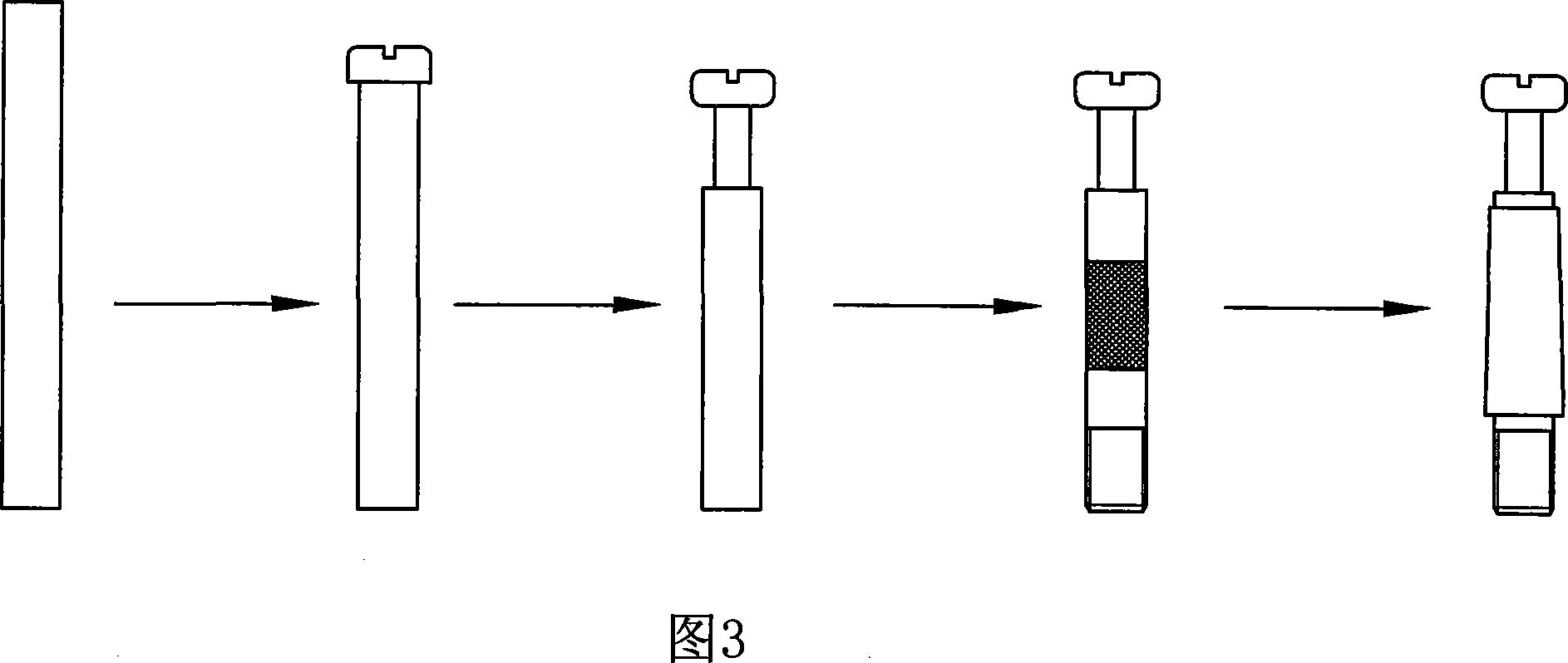

[0030] As shown in Figure 6, a production process of a connecting rod for furniture: the production process includes the following parts:

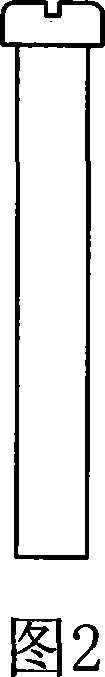

[0031] 1. The semi-finished product of the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com