Device and method for measuring stress of optical glass

A technology for optical glass and stress measurement, which can be used in measuring devices, measurement of the change force of optical properties of materials when they are stressed, and material analysis by optical means. It can solve the problem of measuring the stress of large-diameter optical glass. Direction and its distribution, occupying a huge test space, long test light path and other issues, to achieve the effect of improving test efficiency, accuracy and test speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

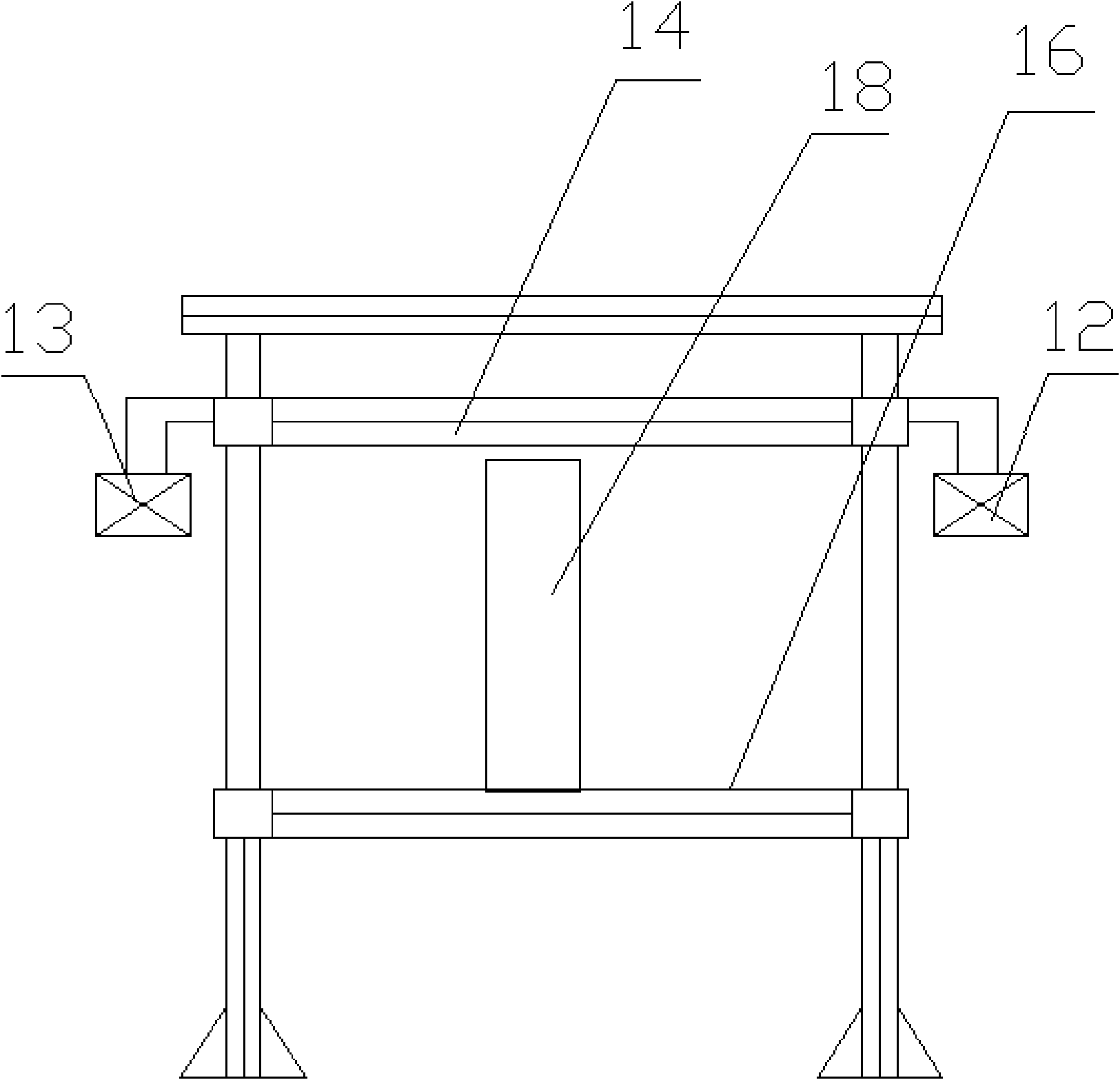

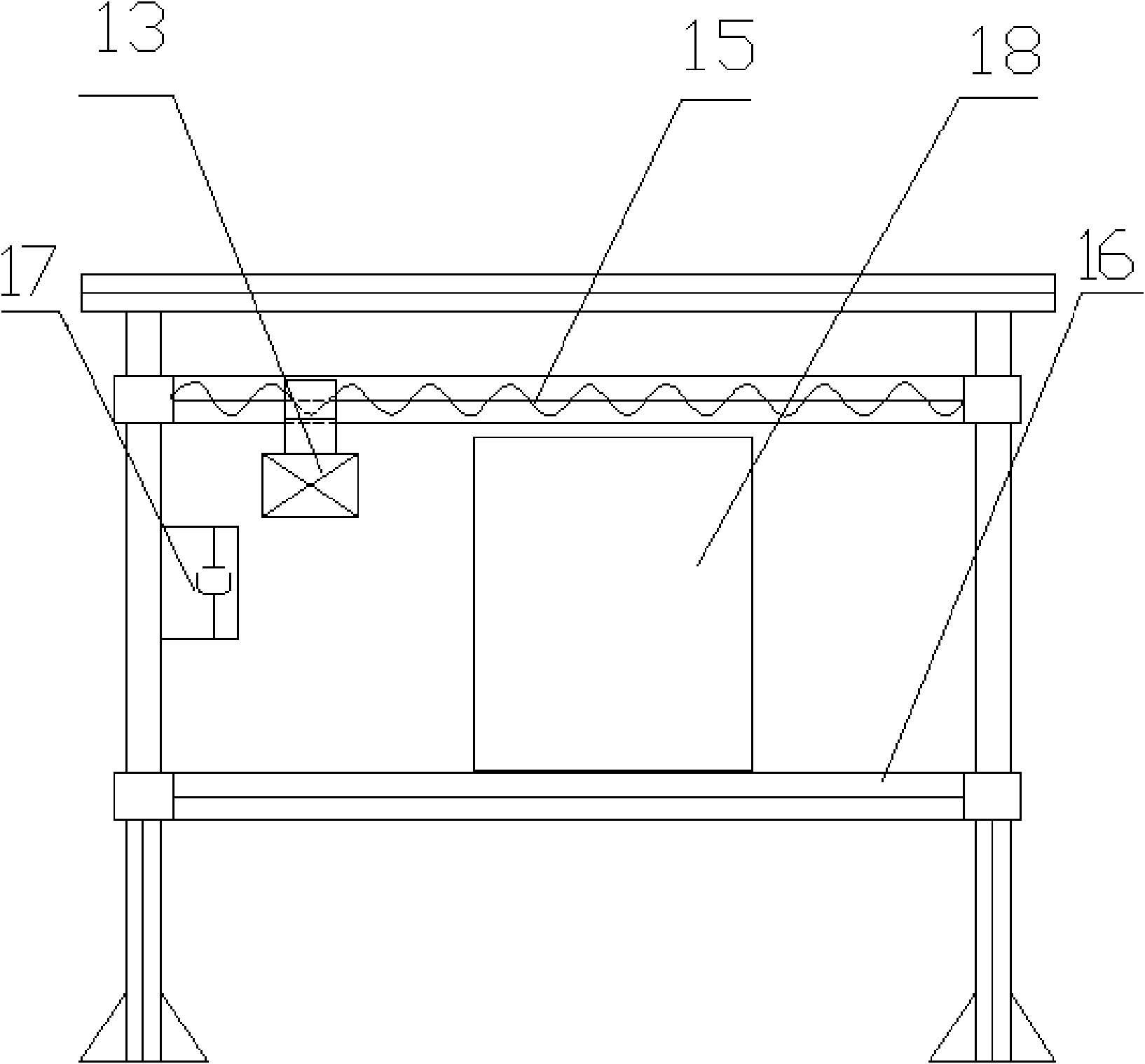

[0025] The optical glass to be tested is made into two kinds of test samples, one is the optical glass stress sample 18 for measuring glass stress, and the shape can be cuboid, such as figure 2 As shown, the other is the photoelastic coefficient sample 22 for measuring the glass photoelastic coefficient, which is cylindrical in shape, such as Figure 4 shown.

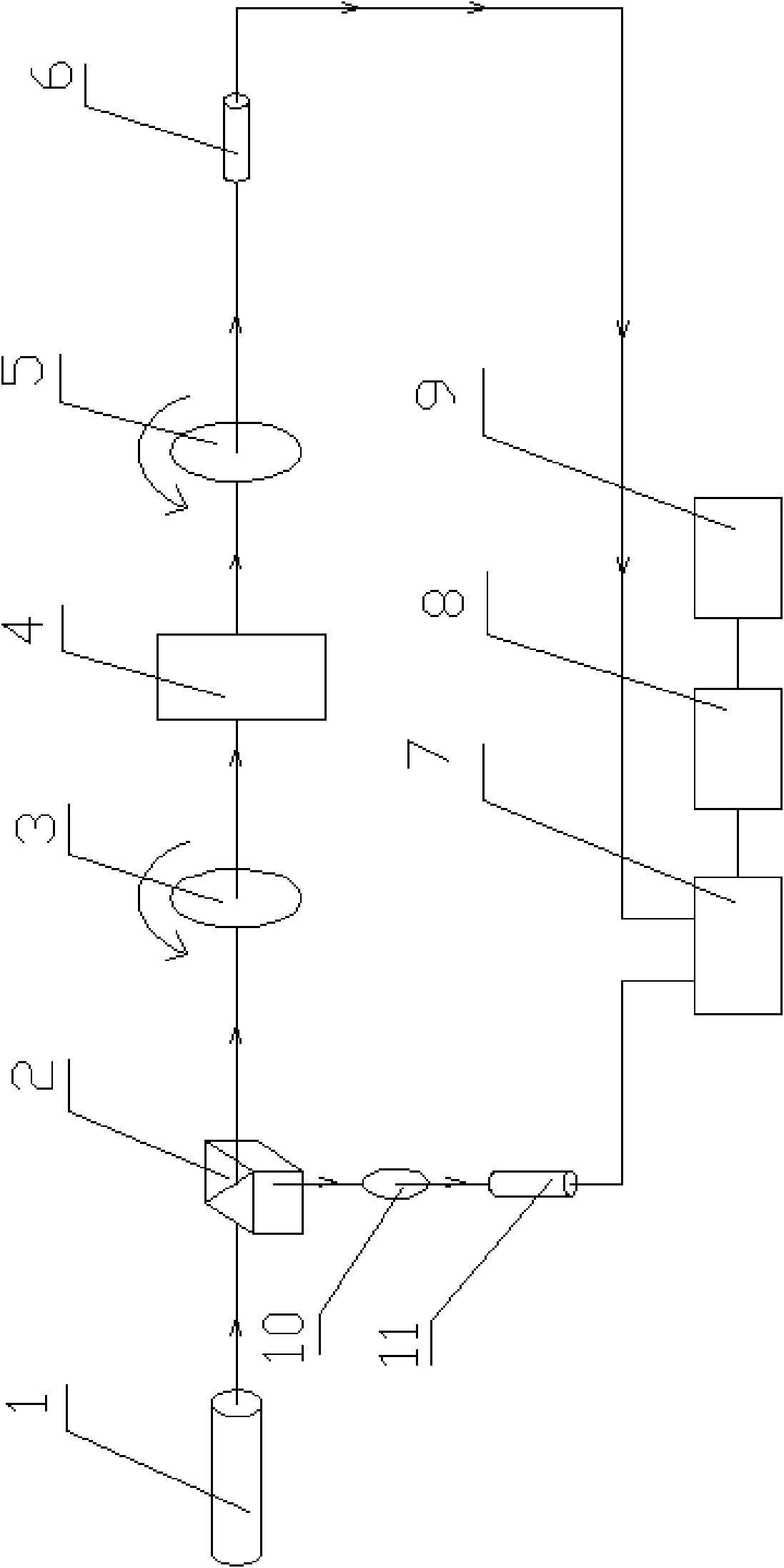

[0026] Such as figure 2 with image 3 As shown, the device of the present invention is composed of a common optical path interferometer and a frame, wherein the stable transverse Zeeman laser 1, the half-transparent mirror 2, the synchronously rotating half-wave plate 3, and the second polarizer in the common optical path interferometer 10. The second laser detector 11 is placed in the laser emitting unit 12; the first polarizer 5 and the first laser detector 6 are placed in the laser receiving unit 13, and the phase meter 7, the A / D converter 8 and the computer 9 Place it in any position; the frame includes a squa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com