Constant temperature parameter variable electric heating system

A technology of electric heating and power supply system, which is applied in the direction of electric furnace heating, ohmic resistance heating, electric heating devices, etc., and can solve problems such as inability to adapt to complex and changeable, fixed constant temperature parameters, and inability to adapt to different needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

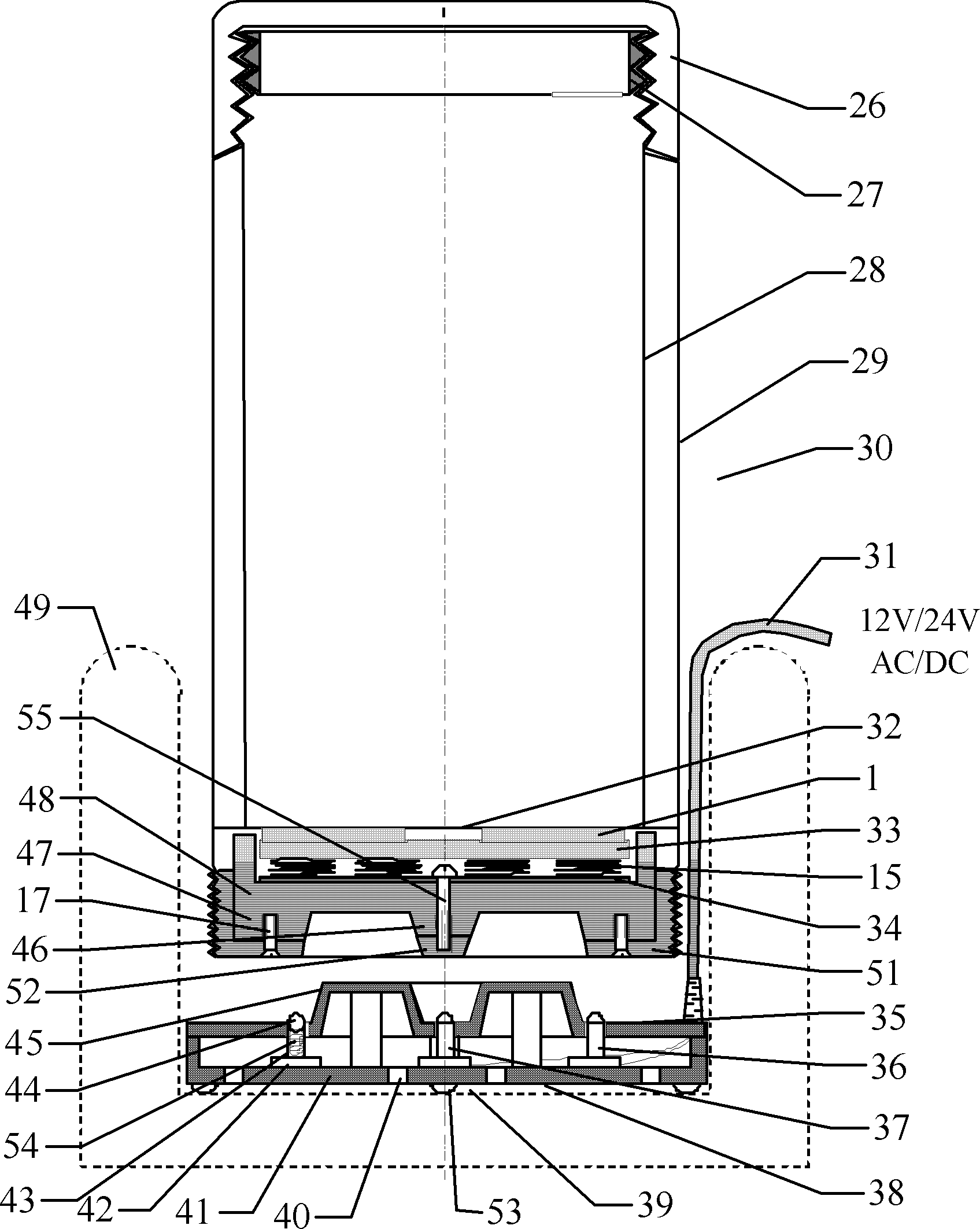

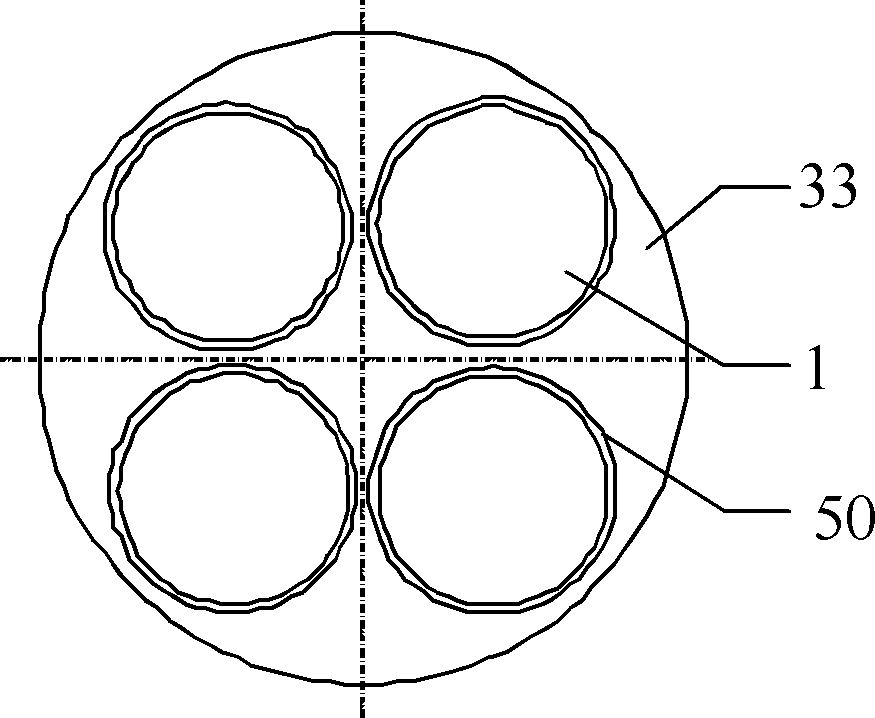

Embodiment 1

[0097] figure 1 It shows an embodiment of PTC electric constant temperature cup and power supply system. The cup inner bottom part 32 of the PTC electric constant temperature cup 30 adopts a stainless steel plate, and four circular PTC heating elements 1 are arranged in four grooves 50 of the electrode plate 33, see figure 2 . The four circular PTC heating elements 1 have a diameter of 20mm, a thickness of 1.5mm, a surface temperature of 60±5°C, and an operating voltage of 12V. The disc-shaped electrode plate 33 is made of aluminum plate with a thickness of 3mm and a groove depth of 0.7mm. The PTC heating element 1 is pressed on the lower side of the cup inner bottom 32 by the disc-shaped electrode plate 33 and the spring 15 at its lower part. The lower side of the spring 15 is a metal conductive plate 34 and an outer bottom member 48, and the metal conductive plate 34 is made of an aluminum plate with a thickness of 1mm. The outer bottom part 48 adopts plastic injection m...

Embodiment 2

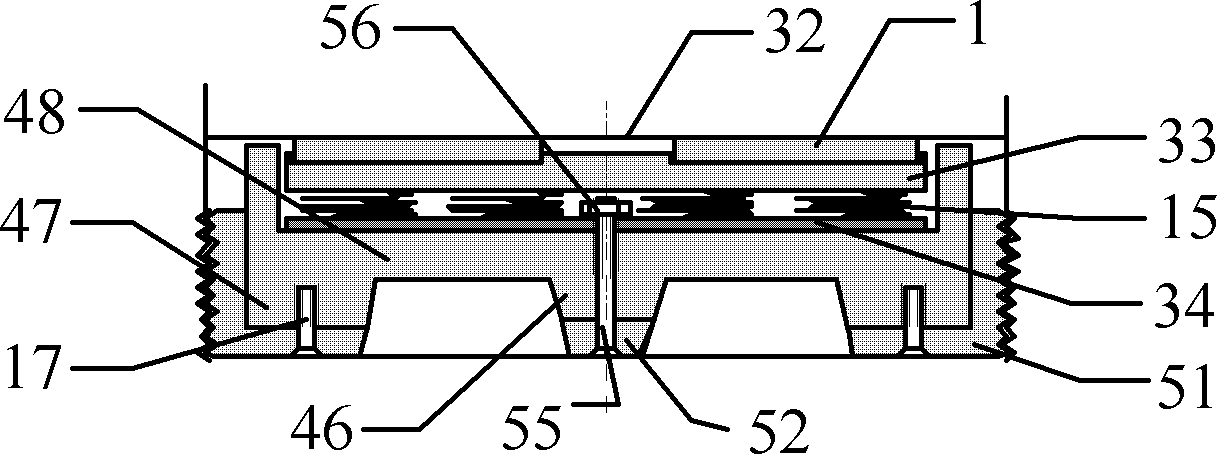

[0099] The difference between this embodiment and Embodiment 1 is that the central electrode pole shoe 52, such as image 3 As shown, the screw 55 passes through the central electrode pole piece 52 with a through hole, and the outer bottom member 48 and the through hole of the metal conductive plate 34 are fixed with the nut 56 on the upper part thereof. The embodiment of the central electrode seat 12 and the central electrode pole shoe 30 is defined as mode B.

Embodiment 3

[0101] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the central electrode pole piece 52 is enlarged to completely replace the central electrode seat 46, adopts a circular frustum shell structure, and is installed in a circular groove of the outer bottom member 48, and the screw 55 passes through A through hole at the center of the metal conductive plate 34 and the outer bottom member 48 is fixed with a nut 56 welded in the frustum shell. The central electrode shoe of the circular frustum shell is stamped and formed by stainless steel plate. Spring 15 adopts leaf spring. The embodiment of the central electrode holder 12 and the central electrode shoe 30 is defined as mode C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com