High-strength and highly fatigue-resistant steel rail and production method thereof

a production method and high-strength technology, applied in the field of high-strength, highly wear-resistant, and highly contact fatigue-resistant steel rails and production methods thereof, can solve the problems of increasing the need for high contact fatigue resistance performance and high wear resistance performance of freight railways

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

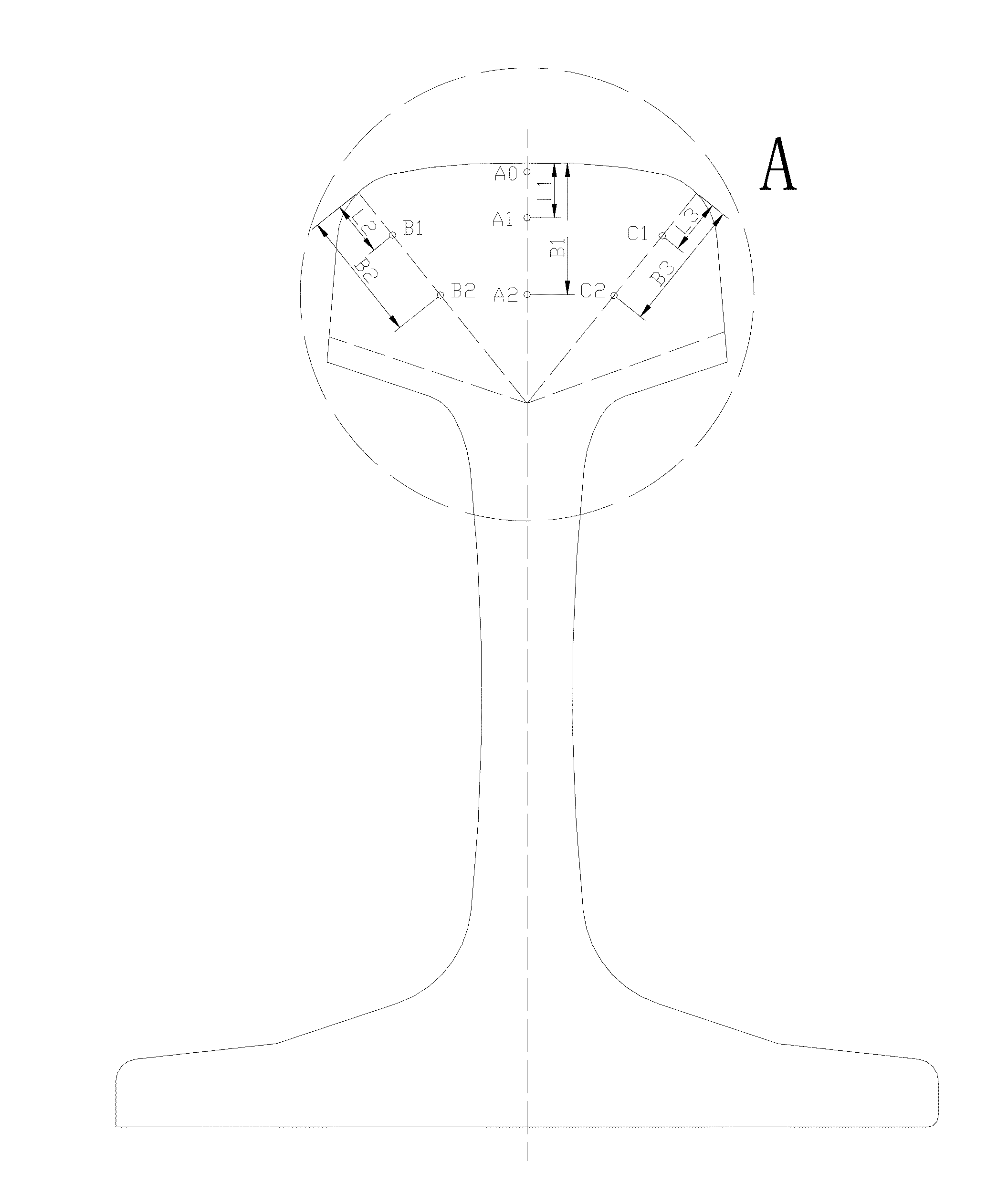

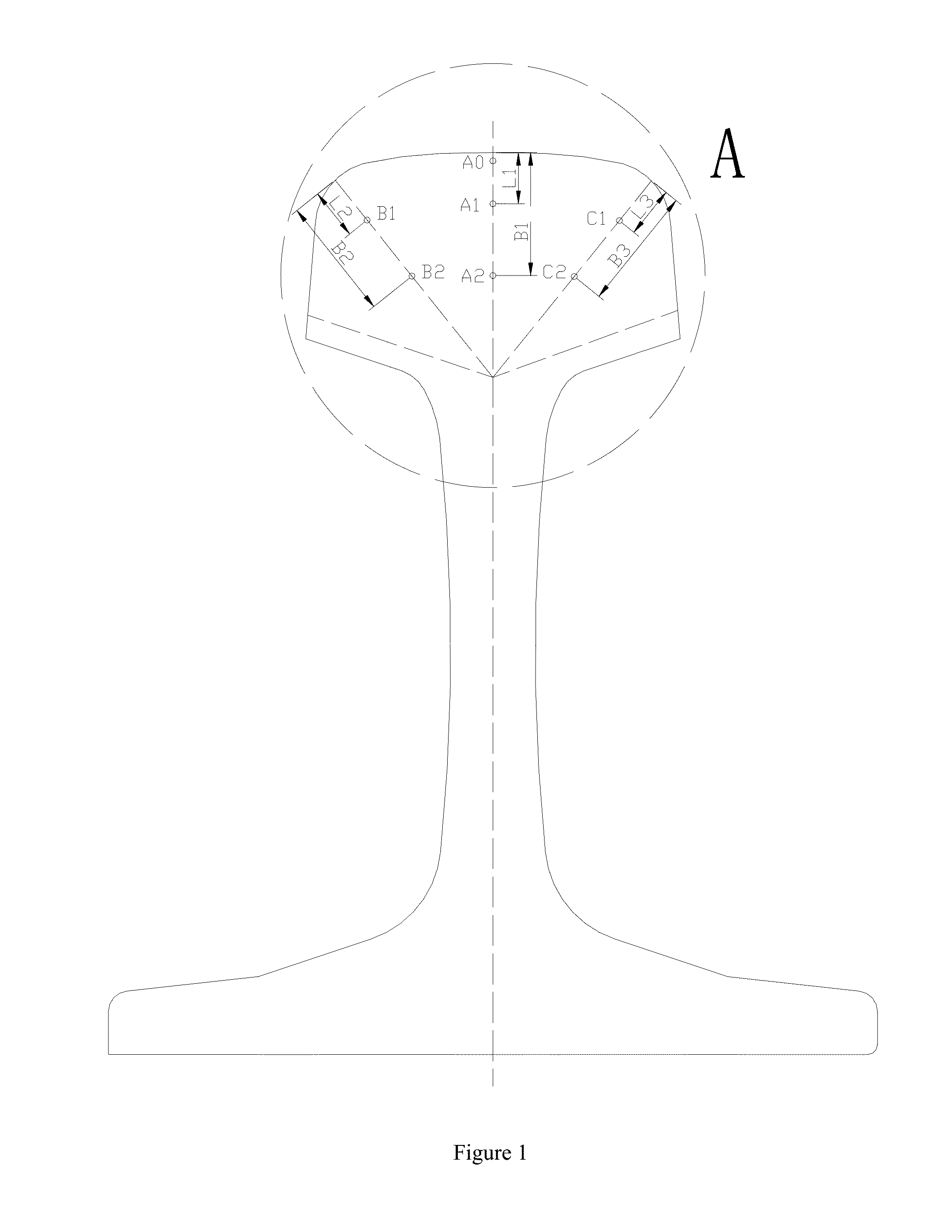

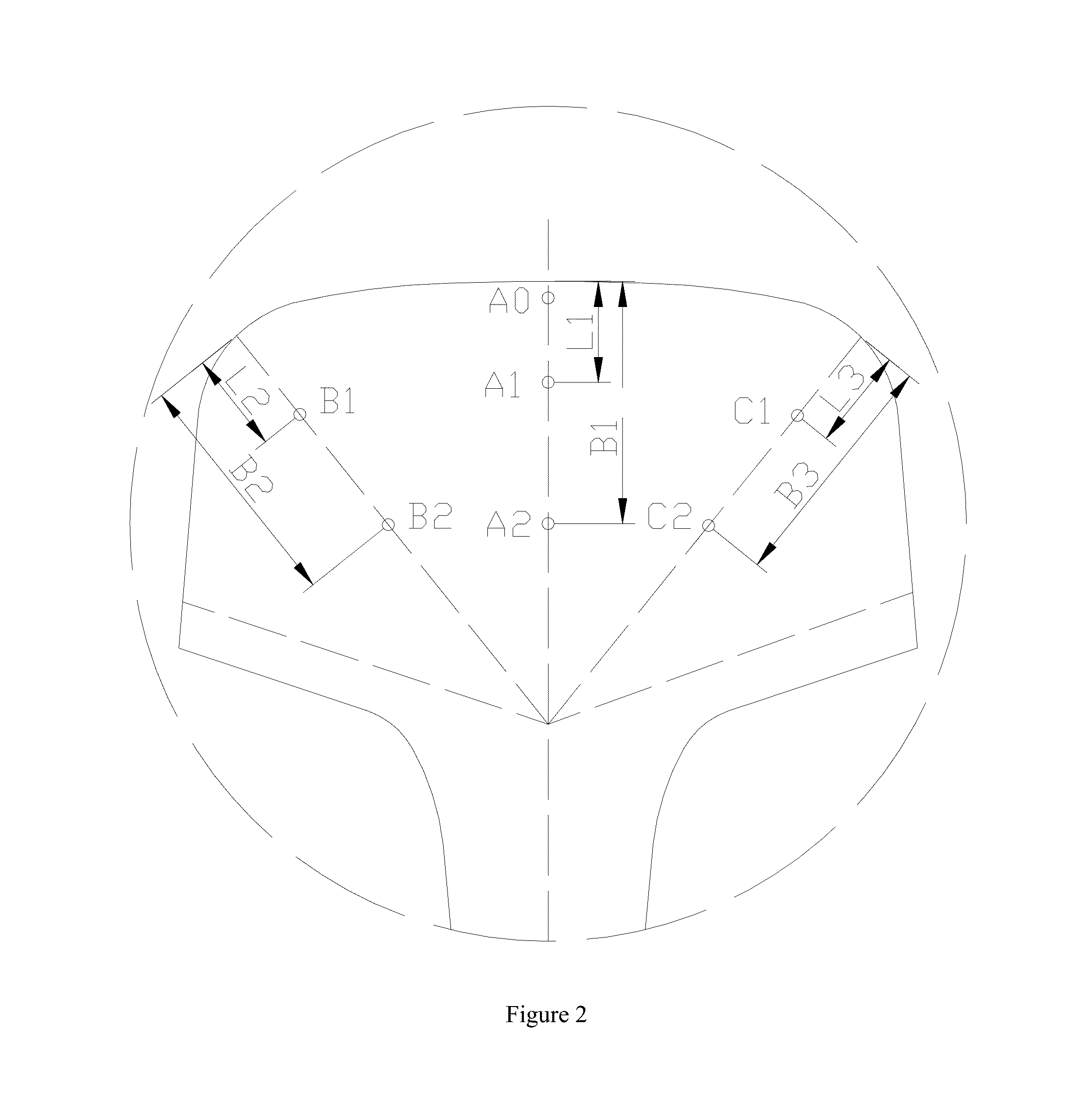

Image

Examples

example

[0043]The production procedures include: rail steel smelting in a converter-refining in a LF furnace and molten steel heating-RH composition control and homogenization-bloom continuous casting under six-strand protection-bloom heating-7-stand universal rolling-feeding the rolled steel with ends into heat treatment equipment for forced cooling-discharging from the heat-treatment equipment at 300° C.˜400° C. final cooling temperature-cooling on walking beam cooler-combined vertical and horizontal straightening-non-destructive test, cross sectional dimension and straightness inspection-combined cutting and drilling, and cutting to specified length-surface inspection-warehousing.

[0044]The temperature of the rolled part is 930° C.˜1,000° C. when the rolled part is discharged from the UF finish rolling section. To ensure the initial cooling temperature is 780° C.˜880° C., the running speed of the roller way must be increased, and relevant pause procedures must be cancelled, so that the ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com