Forging method of bearing ring

A bearing ring, rapid cooling technology, applied in the field of bearing ring forging, can solve the problems of hindering bearing service life, coarse carbide particles, uneven distribution, etc., to achieve the effect of improving contact fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

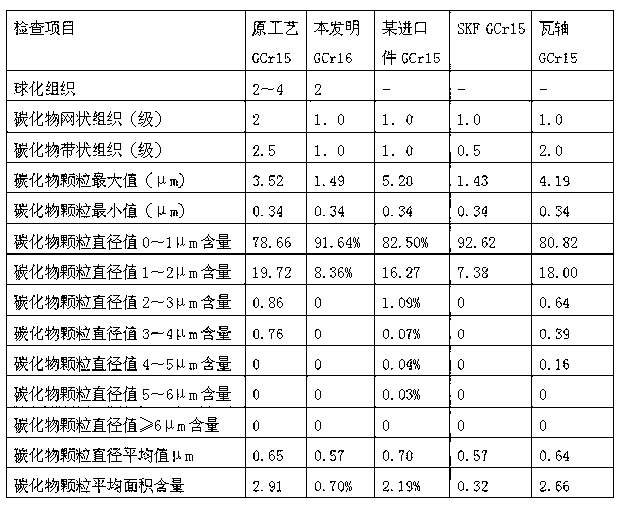

[0015] It is generally believed that contact fatigue damage is one of the main factors affecting the service life of bearings. Local damage of metal uniformity and continuity, such as non-metallic inclusions, large-grained carbides, air bubbles, etc., will cause local distortion of the stress field, increase the stress, and cause micro-cracks on or below the metal surface, eventually leading to bearing damage. Therefore, the uniformity of non-metallic inclusions and carbides in bearing steel is an important factor affecting the service life of bearings. Therefore, one of the keys to improving the service life of bearings is to improve the unevenness of carbides.

[0016] Some research data show that: for low and medium strength steel, the sample is in 10 7 No failure will occur after one fatigue test cycle, when the loaded stress amplitude is lower than the fatigue strength of traditional high-strength steel, the cycle number is greater than 10 7 , fatigue failure occurs. F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com