Method for improving fatigue strength of coating layer by double-layer texture coupling effect

A fatigue strength and texture technology, applied in the direction of pressure inorganic powder coating, etc., can solve the problems of reduced life, high porosity, crack propagation of spray coating, etc., and achieve the effect of prolonging service performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Preparation of a double-layer texture-coupled coating

[0030] first step:

[0031] Firstly, the substrate is cleaned and polished, and the substrate is preferably stainless steel, specifically FV520B.

[0032] Step two:

[0033] Fabrication of Textured Patterns on Substrate Surfaces Using a Laser Process

[0034] First, make circular and triangular combined textures, circular and grooved combined textures, grid textures, and hexagonal texture patterns in the drawing software, and then use laser processing to prepare textures on the surface of the substrate pattern.

[0035] Among them, the circular and triangular combined texture, the diameter of the circle is 150 microns, the distance between the centers of the circles is 200 microns, and a triangle with a side length of 100 microns is prepared in the gap between the circles and the circles;

[0036] Circular and groove-shaped combined texture, wherein the grooves have a width angle of 150 microns and a ...

Embodiment 3

[0054] Example 3 The rolling contact fatigue test was carried out on the coating prepared in Example 1, and the slip rate of contact fatigue was changed to observe the anti-fatigue performance of the coating under different slip rate conditions.

[0055]In order to measure various properties of the coating, a Nova NanoSEM450 scanning electron microscope was used to observe the geometric shape of the texture after spraying.

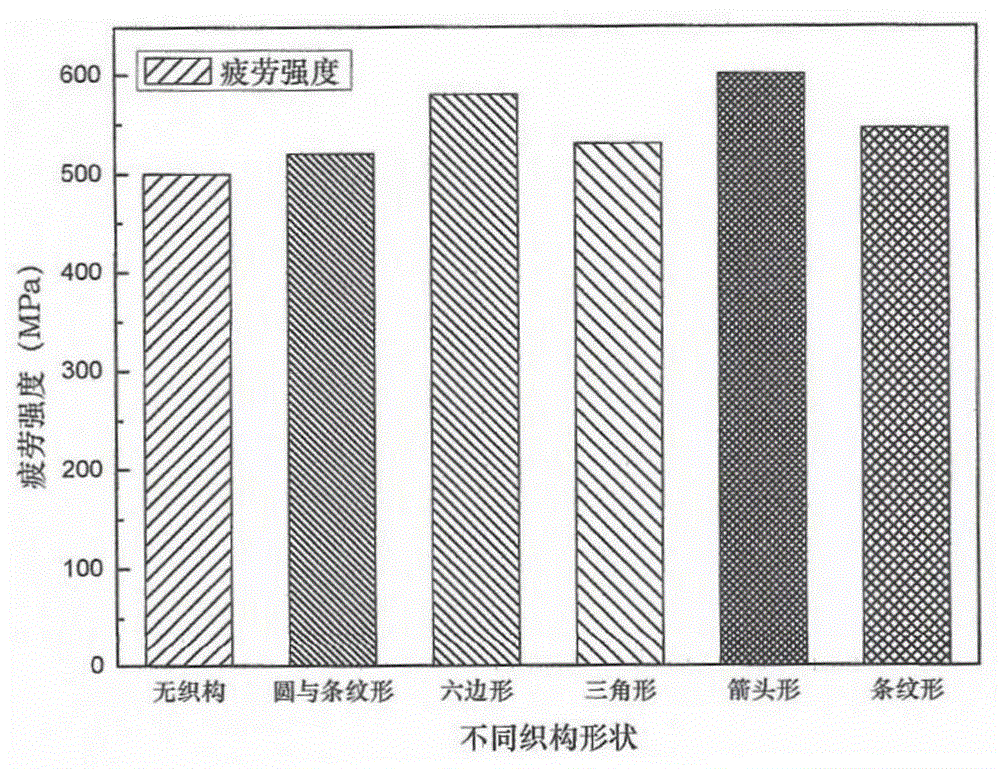

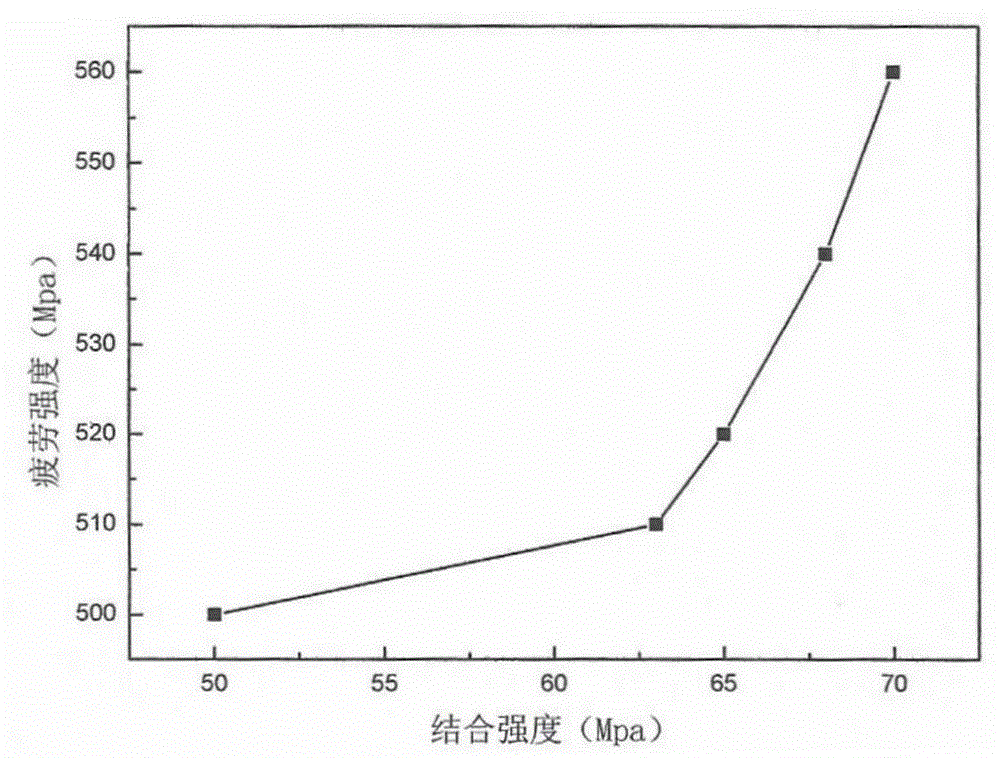

[0056] In order to test the effect of different texture patterns on the fatigue resistance of sprayed coatings, the rolling contact fatigue testing machine was used to test the fatigue properties of sprayed coatings.

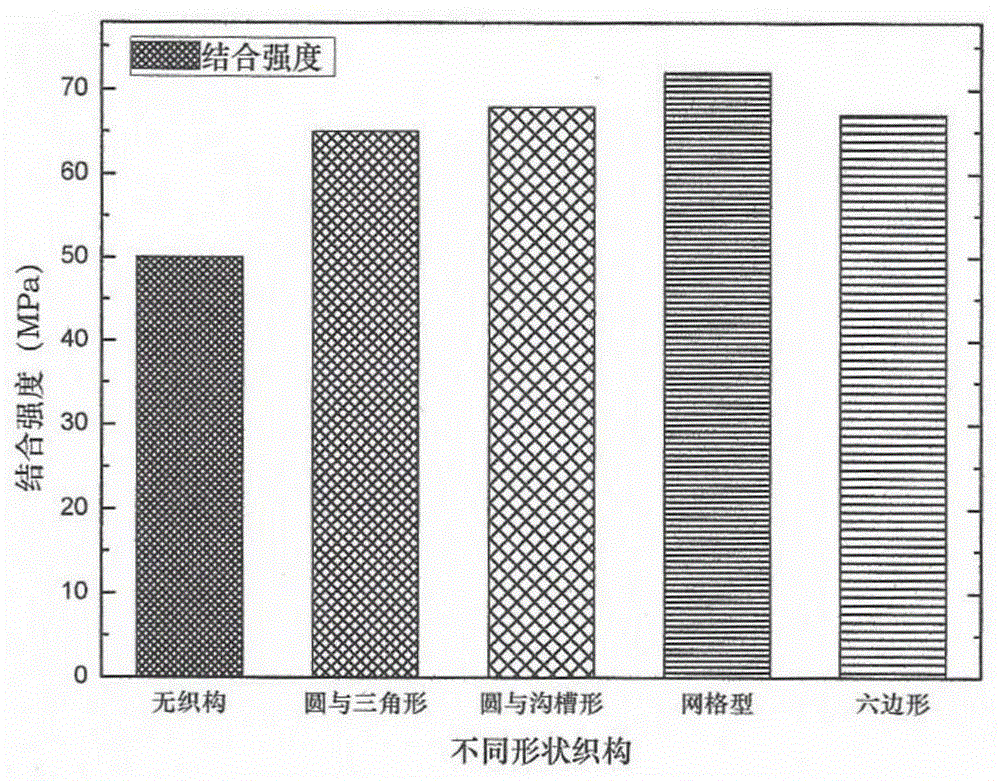

[0057] 1. The bonding strength between the coating and the substrate under different shapes and textures on the surface of the substrate

[0058] The bonding strength of the coating is tested by a tensile testing machine, the model of the tensile testing machine used is: MTS809 electronic universal material testing machine. The manufacturer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fatigue strength | aaaaa | aaaaa |

| Fatigue strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com