Method for lubricating screw expanders and system for controlling lubrication

a screw expander and screw technology, applied in the direction of liquid fuel engines, liquid degasification, separation processes, etc., can solve the problems of large system footprint, low cycle efficiency, and low amount of power recoverable from the cycl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

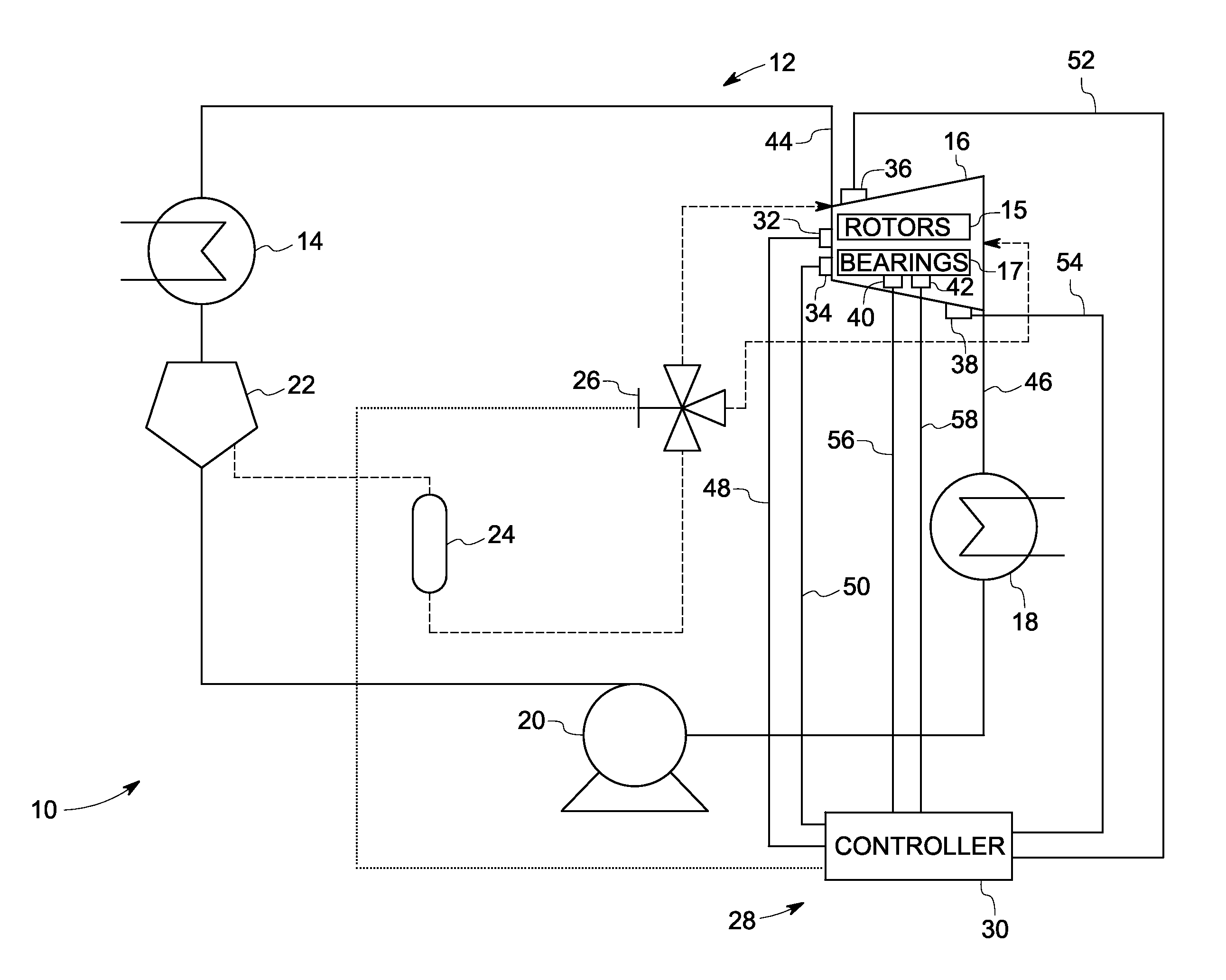

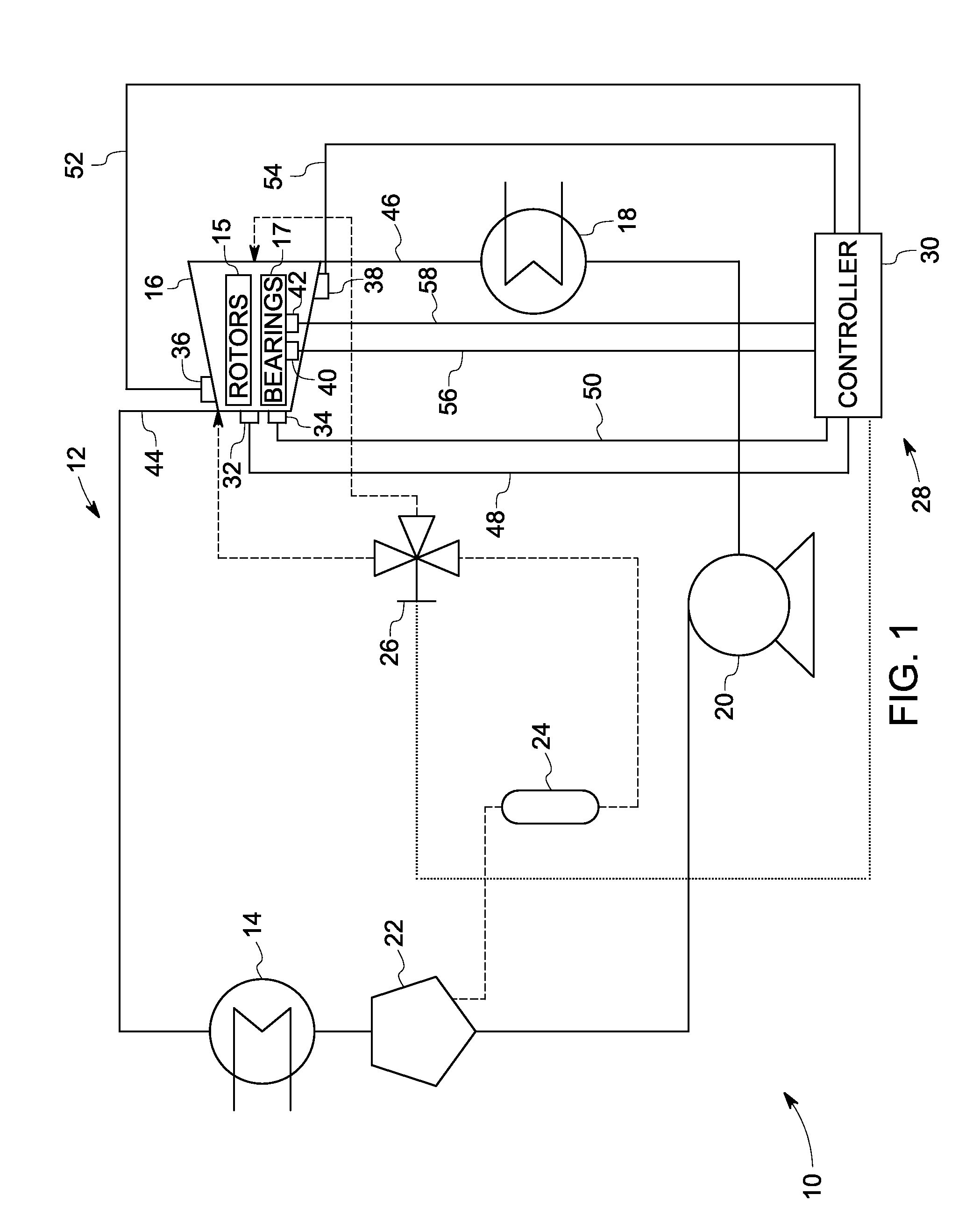

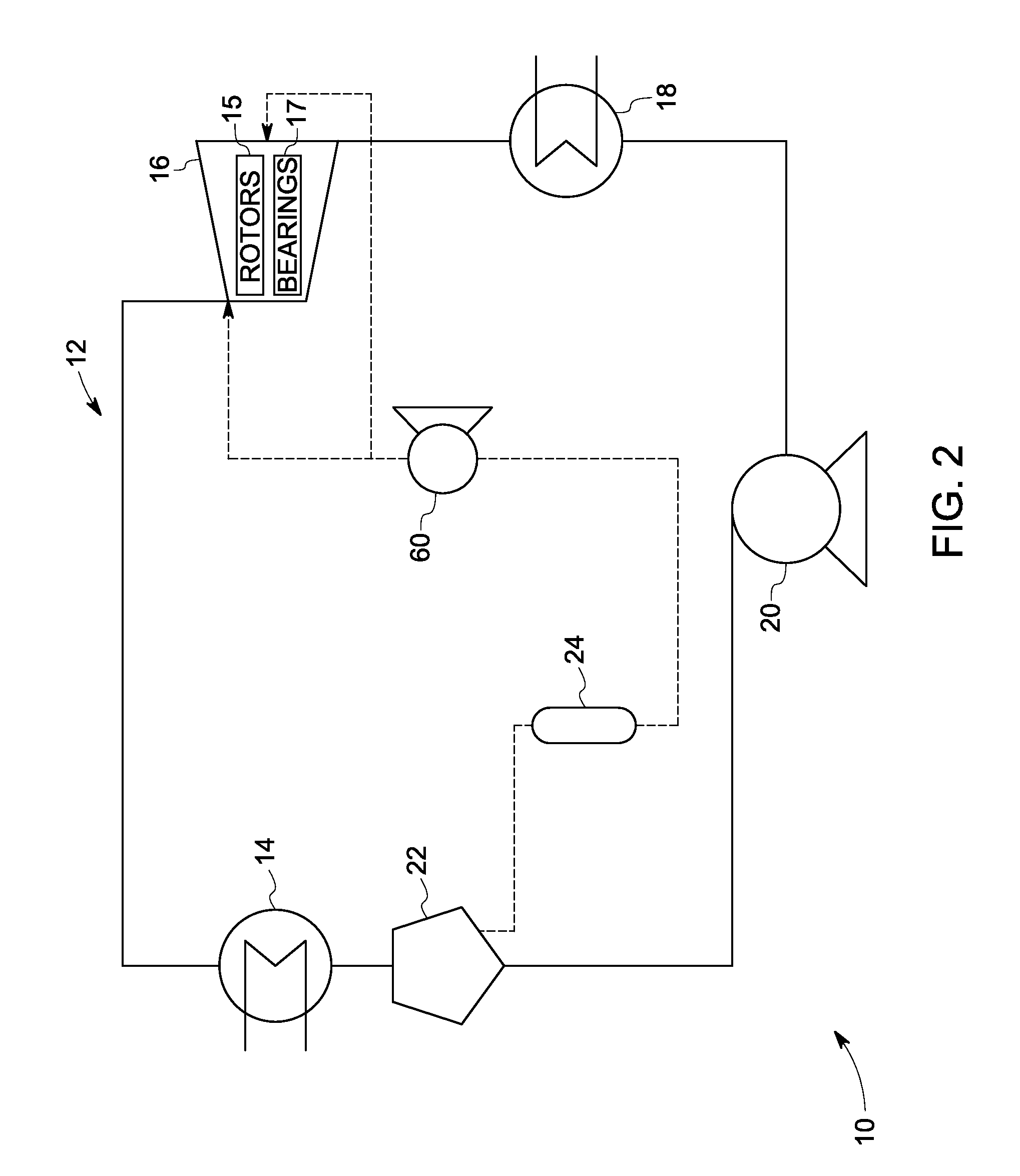

[0017]As discussed in detail below, embodiments of the present invention provide a method for lubricating an expansion machine, for example, a screw expander using a mixture of working fluid and lubricant in an organic rankine cycle system. The method includes condensing the mixture of working fluid and lubricant fed from the screw expander through a condenser. The mixture of working fluid and lubricant fed from the condenser is pressurized from a first pressure to a second pressure through a pump. The lubricant is separated from the condensed working fluid and fed to the screw expander. Alternatively, a portion of the mixture of the condensed working fluid and lubricant is fed to the expander. In certain embodiments, the feeding of the separated lubricant or the portion of the mixture of condensed working fluid and lubricant to the screw expander is controlled based on one or more parameters related to the screw expanders. In some embodiments, a control system for controlling lubri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com