High-strength heat-resistant rubber-based composite for automobile brake pad and application and preparation method thereof

A technology of heat-resistant rubber and composition, applied in chemical instruments and methods, friction linings, mechanical equipment, etc., can solve the problems of high temperature recession, high overall cost and difficult to promote, etc., to reduce thermal decay, ensure braking safety, Good thermal crack resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

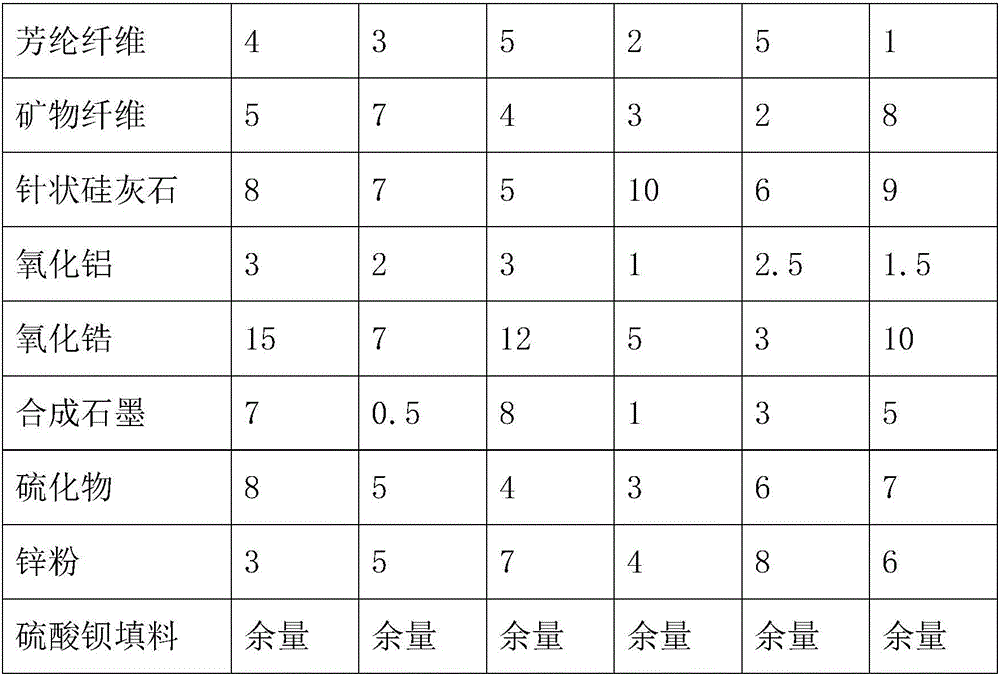

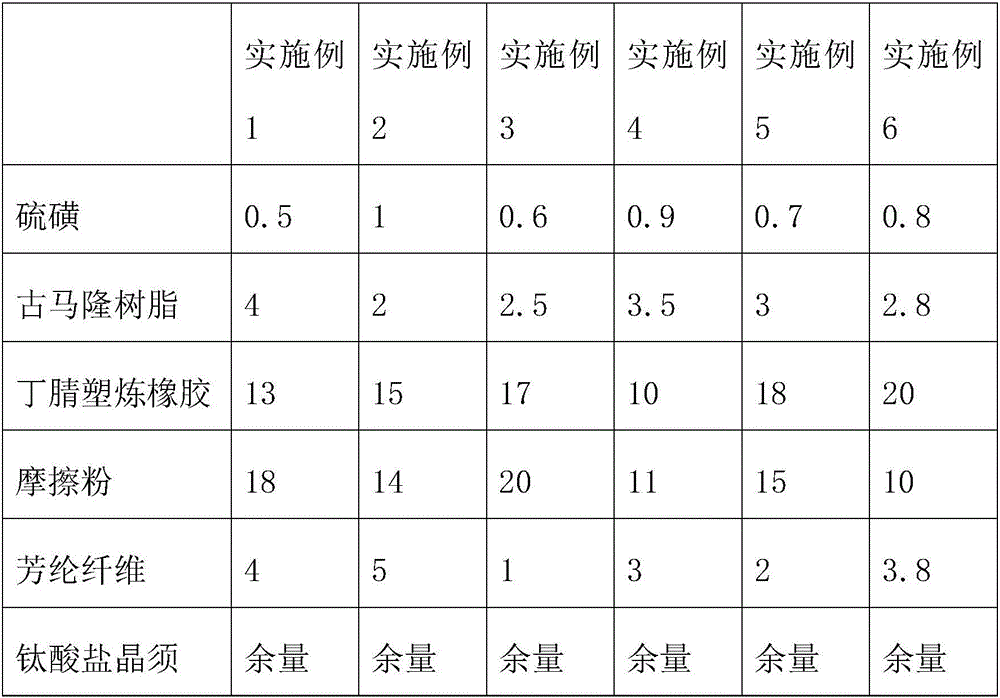

Examples

experiment example 1

[0060] Use the same test conditions to test the coefficient of friction, compressive strain, impact strength, weight loss after the AK-MASTER test, and whether there are cracks on the surface after the test of the X1 prepared in the comparative example and the composition of Examples 1-6. See Table 2 for specific data comparison.

[0061] The X1 that table 3 comparative example makes and the performance effect data of the composition of embodiment 1-6

[0062]

[0063] As can be seen from Table 2, the performance of the high-strength heat-resistant rubber-based composition for automobile brake pads provided by the present invention is significantly better than that of X1, which may be due to the fact that each component in the composition of the present invention produces In order to realize the effect of synergy, it is found through comparative data that the nominal friction coefficient of the X1 formula is 0.45, which is relatively high, and the thermal recession coeffici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com