Positioning sleeve part for spindle brake device of braider

A technology of a braking device and a positioning sleeve, which is applied in the field of knitting machines, can solve the problems of unable to brake the bobbin, the pressure spring is easy to break, and the elastic range is small, and the effect of the spindle braking is sensitive and the adjustment is convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

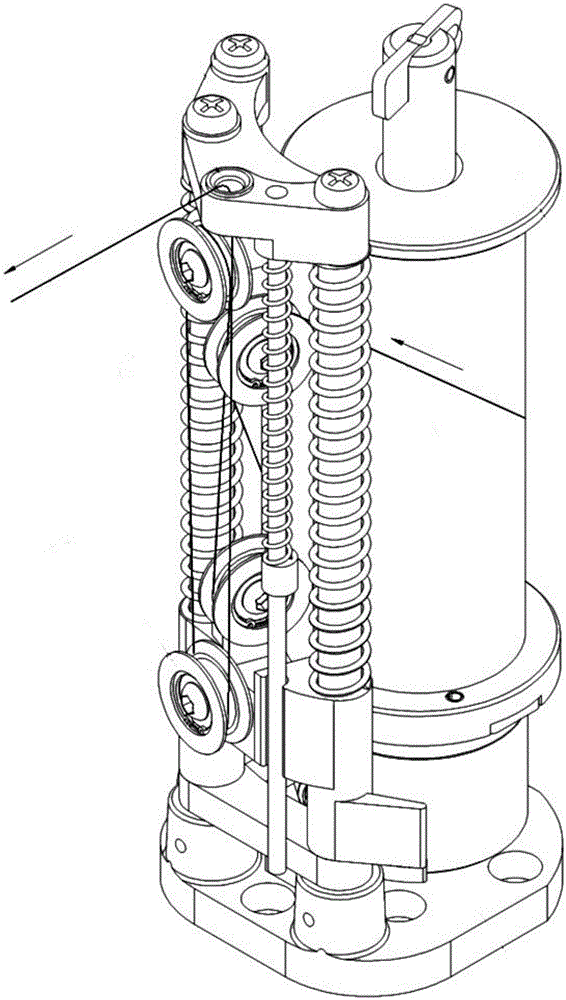

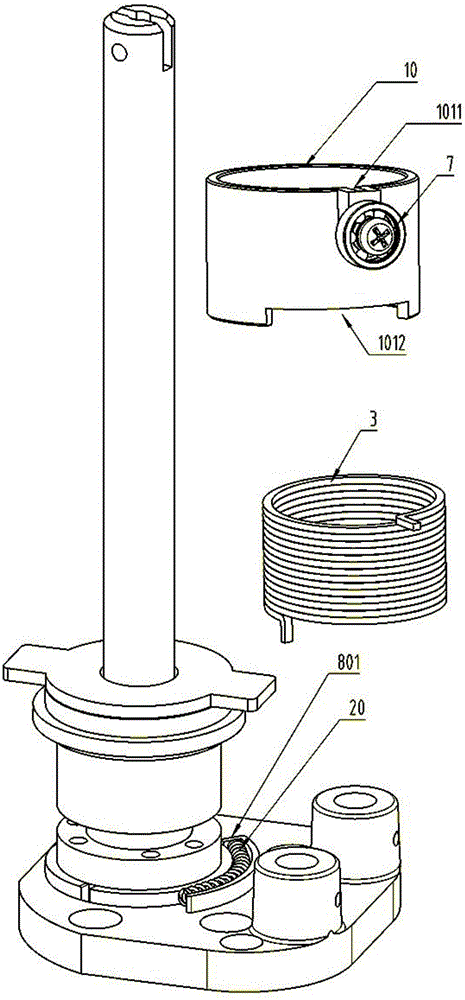

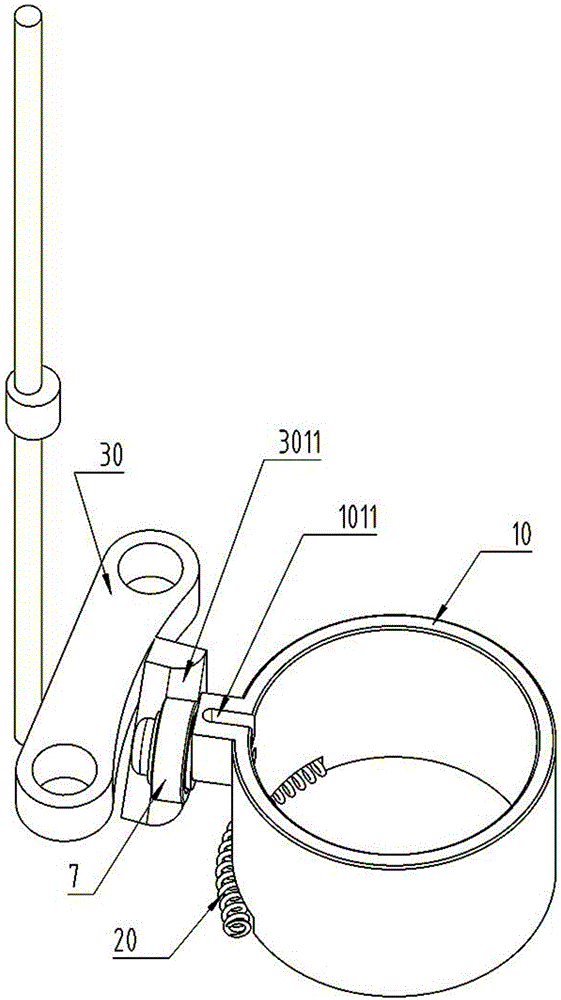

[0027] The structure of the positioning sleeve parts of the braiding machine spindle brake device is as follows: Figure 5 - Figure 9 As shown, it includes: positioning sleeve 1, adjustment seat 2, steel wire torsion spring seat 4, steel wire torsion spring 5, push-pull piece 6, roller 7;

[0028] see Figure 8 and Figure 9 , the positioning sleeve 1 is a cylinder, and a steel coil torsion spring 3 is installed in the middle through hole; the middle through hole and the outer wall of the positioning sleeve cylinder are not arranged on the same axis line, and a convex positioning collar is arranged at the lower end of the positioning sleeve 15. The convex ring 15 of the positioning sleeve and the through hole in the middle of the positioning sleeve 1 are set on the same axis, and the convex ring of the positioning sleeve rests on the pit at the upper end of the adjustment seat 2; the upper end of the positioning sleeve 2 is provided with a bayonet 11 for Accommodate the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com