Environmentally friendly high performance grinding material composition

A friction material and composition technology, applied in friction linings, gear transmission mechanisms, and other chemical processes, can solve problems such as high-temperature braking instability, low heavy metal content, and large environmental hazards, and achieve no brake squeal Good sound and comfort performance, good performance of high temperature and thermal decay resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

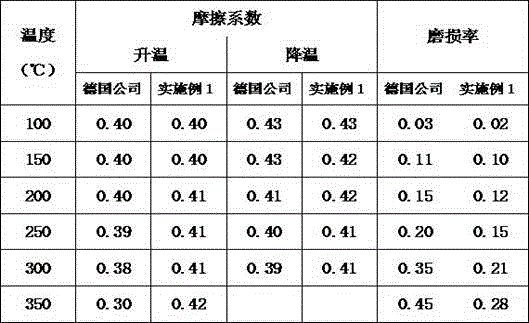

Embodiment 1

[0012] Example 1: 5.5 parts by weight of fused magnesia (100 grams per part, the same below), 0.2 parts of fused zirconia, 4 parts of aramid fiber, 2.5 parts of tire powder, 6 parts of expanded vermiculite, ceramic fiber 9 parts, 3.5 parts of magnetite, 1 part of multi-walled carbon nanotubes, 7.5 parts of boron phenolic resin, 5 parts of benzoxazine resin, 2.5 parts of aminosilane, 16 parts of calcium sulfate whiskers, 16 parts of potassium titanate whiskers , 5.5 parts of flake graphite, 6 parts of cashew oil friction powder, 6 parts of calcined petroleum coke, 2 parts of boron nitride, 5 parts of flake aluminum powder, 3 parts of nano-titanium dioxide, 0.6 part of silicon carbide, 1 part of tantalum carbide, zirconium silicate 8 parts, 2 parts of nano-zinc oxide, and 2 parts of molybdenum trioxide were poured into a high-speed disperser, stirred to form a uniformly dispersed powder friction material composition, and then the friction material composition was taken out and pu...

Embodiment 2

[0013] Embodiment 2: 5 parts of fused magnesia, 0.25 parts of fused zirconia, 4.5 parts of aramid fiber, 2.0 parts of tire powder, 5 parts of expanded vermiculite, 10 parts of ceramic fiber, 5 parts of magnetite, 2 parts of multi-walled carbon nanotubes, 7.4 parts of boron phenolic resin, 3 parts of benzoxazine resin, 2 parts of aminosilane, 15 parts of calcium sulfate whiskers, 17 parts of potassium titanate whiskers, 6.5 parts of flake graphite, cashew nut oil friction 7.5 parts of powder, 7 parts of calcined petroleum coke, 1.5 parts of boron nitride, 7 parts of flake aluminum powder, 5 parts of nano-titanium dioxide, 0.4 parts of silicon carbide, 2 parts of tantalum carbide, 7 parts of zirconium silicate, 1 part of nano-zinc oxide, Pour 1 part of molybdenum trioxide into a high-speed disperser, stir to form a uniformly dispersed powder friction material composition, then take out the friction material composition and put it into a forming mold for compression molding, then ...

Embodiment 3

[0014] Embodiment 3: 6 parts of fused magnesia, 0.3 part of fused zirconia, 5 parts of aramid fiber, 2.2 parts of tire powder, 5.5 parts of expanded vermiculite, 8.5 parts of ceramic fiber, 4 parts of magnetite, 1.5 parts of multi-walled carbon nanotubes, 7 parts of boron phenolic resin, 4 parts of benzoxazine resin, 3 parts of aminosilane, 17 parts of calcium sulfate whiskers, 18 parts of potassium titanate whiskers, 7 parts of flake graphite, cashew nut oil friction 8 parts of powder, 8 parts of calcined petroleum coke, 1.8 parts of boron nitride, 6 parts of flake aluminum powder, 4.2 parts of nano-titanium dioxide, 0.5 parts of silicon carbide, 1.5 parts of tantalum carbide, 6 parts of zirconium silicate, 1 nanometer of zinc oxide.5 Pour 1.5 parts of molybdenum trioxide into a high-speed disperser, stir to form a uniformly dispersed powder friction material composition, then take out the friction material composition and put it into a forming mold for compression molding, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com