Electric control brake system used for trailer

A technology for electronically controlling brakes and motors, applied in the directions of brakes, brake transmissions, vehicle components, etc., can solve the problems of inability to meet the requirements of reversing use, inability to adjust braking characteristics, insensitive trailer braking, etc. Adjustable characteristics, sensitive braking, and the effect of improving ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

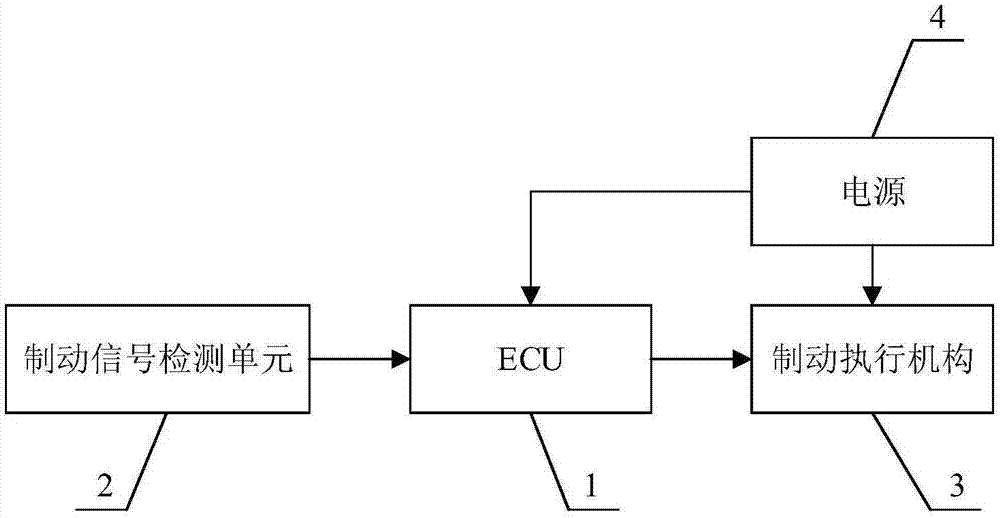

[0025] Such as figure 1 As shown, the present invention is used for the electronically controlled braking system of the trailer, including an electronic control unit 1, a braking signal detection unit 2, a brake actuator 3 and a power supply 4, and the signal input terminal of the electronic control unit 1 is connected to the braking system. The signal output terminal of the signal detection unit 2 is connected, the signal output terminal of the electronic control unit 1 is connected with the signal input terminal of the brake actuator 3, and the power supply 4 is respectively connected with the power input terminals of the electronic control unit 1 and the brake actuator 3 connected.

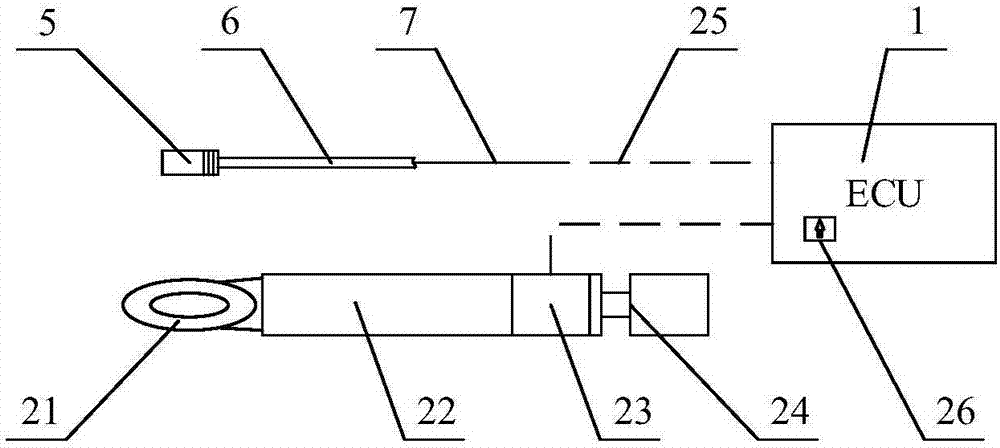

[0026] Such as figure 2 As shown, the brake signal detection unit 2 includes a trailer traction ring 21, a traction connecting rod 22, a force sensor 23 and a buffer 24 connected in series, and also includes a brake signal detection line 25 and a ramp angle detection chip 26;

[0027] The fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com