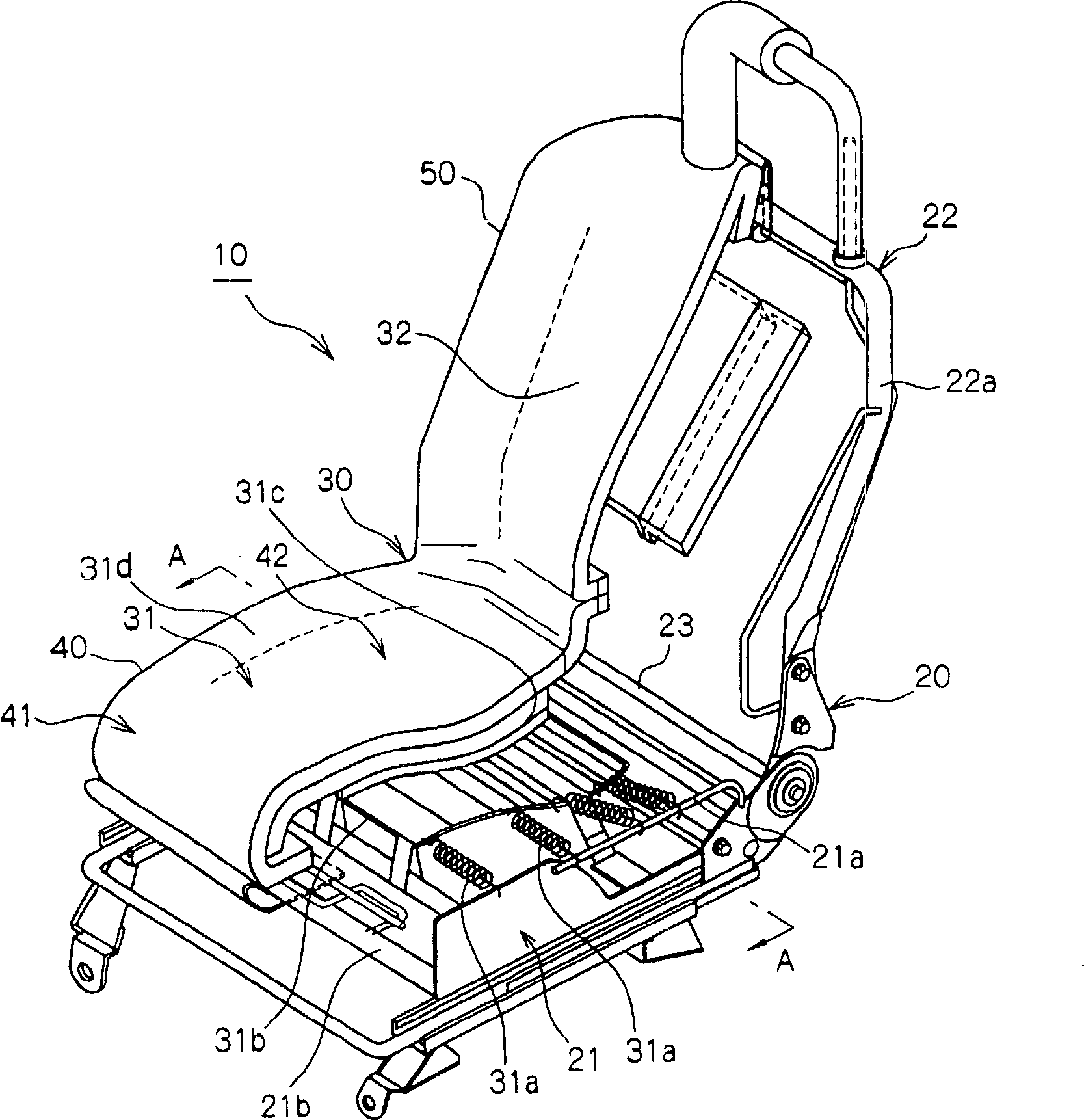

Seat

A technology of seat cushion and seat, applied in the field of seat cushion components, can solve problems such as numbness and poor riding comfort, and achieve the effects of reducing vibration and increasing relative displacement

- Summary

- Abstract

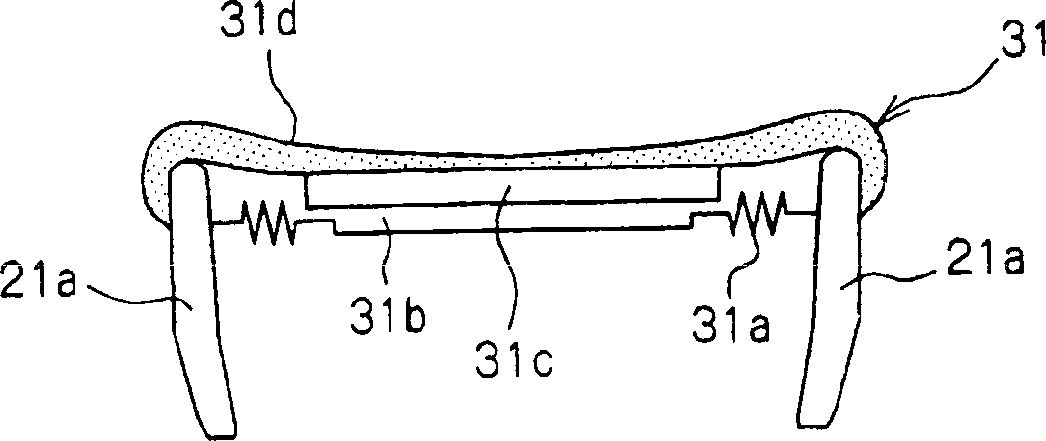

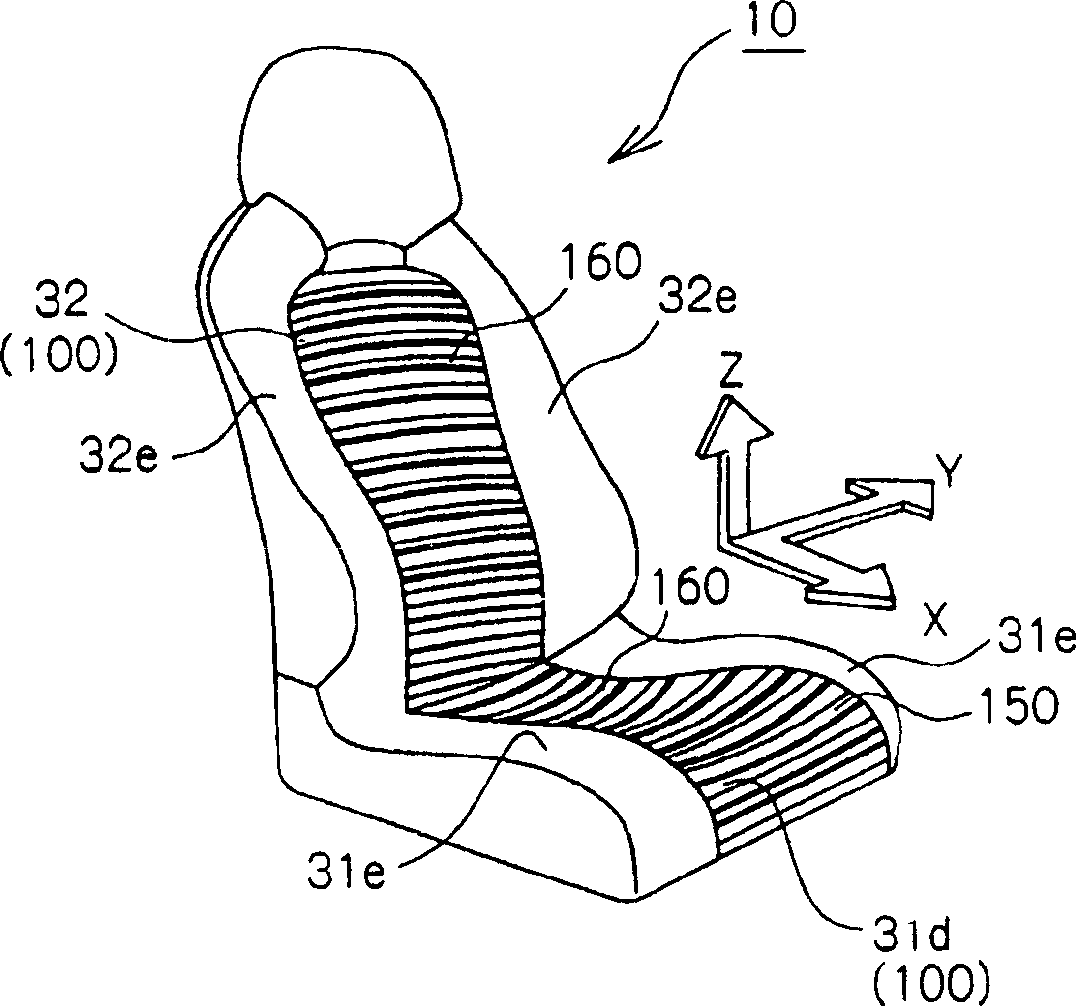

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0194] Knitting machine: Double Raschel knitting machine (Dabururatsucellu knitting machine) (9 gauge / 2.54cm, cylinder pitch 15mm)

[0195] Longitudinal density: 10 pieces / 2.54cm

[0196] Coil row density: 14 / 2.54cm

[0197] Finished thickness (distance between a pair of ground knitted fabric surfaces): 11.5mm

[0198] The ground yarn of one ground knitted fabric: 1170 decitex / 96f polyester BCF multifilament (crimp processing yarn)

[0199] The ground yarn of the other ground knitted fabric: 660 dtex / 192f polyester BCF multifilament (crimp processing yarn)

[0200] Link yarn: 660 decitex / 1f polyester

[0201] The structure of the knit fabric in one place: The change structure of the mesh of 2 courses

[0202] Knitted fabric organization on the other side: fine velvet knitting chain organization

[0203] The total thickness of the loops formed by the ground yarn and the connecting yarn of one ground knitted fabric: 1830 decitex (some are 3000 decitex)

[0204] The total...

manufacture example 2

[0211] Knitting machine: Double Raschel knitting machine (9 gauge / 2.54cm, cylinder spacing 15mm)

[0212] Longitudinal density: 10 pieces / 2.54cm

[0213] Coil row density: 14 / 2.54cm

[0214] Finished thickness (distance between a pair of ground knitted fabric surfaces): 11.5mm

[0215] The ground yarn of one ground knitted fabric: 1170 decitex / 96f polyester BCF multifilament (crimp processing yarn)

[0216] The ground yarn of the other ground knitted fabric: 660 dtex / 192f polyester BCF multifilament (crimp processing yarn)

[0217] Link yarn: 660 decitex / 1f polyester

[0218] The structure of the knitted fabric in one place: the change structure of 2 courses

[0219] Knitted fabric organization on the other side: fine velvet knitting chain organization

[0220] The total thickness of the loops formed by the ground yarn and the connecting yarn of one ground knitted fabric: 1880 decitex (some are 3000 decitex)

[0221] The total thickness of the loops formed by the groun...

manufacture example 3

[0229] Knitting machine: Double Raschel knitting machine (9 gauge / 2.54cm, cylinder spacing 15mm)

[0230] Longitudinal density: 9.8 / 2.54cm

[0231] Coil row density: 12.8 / 2.54cm

[0232] Finished thickness (distance between a pair of ground knitted fabric surfaces): 12.05mm

[0233] The ground yarn of one ground knitted fabric: 1170 decitex / 384f

[0234] The ground yarn of the knitted fabric on the other side: 560 decitex / 70f

[0235] Linking yarn: 560 dtex / 1f

[0236] The organization of one ground knitted fabric: Mesh of 1 pattern cycle (リピ ト ト) 2 courses

[0237] Knitted fabric organization on the other side: fine velvet knitting chain organization

[0238] The total thickness of the loops formed by the ground yarn and the connecting yarn of one ground knitted fabric: 1730 decitex

[0239] The total thickness of the loops formed by the ground yarn and the connecting yarn of the other ground knitted fabric: 1120 decitex

[0240] Compression rate of convex part: 89.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com