High-performance friction material composition containing graphene

A friction material and composition technology, which is applied to friction linings, mechanical equipment, gear transmission mechanisms, etc., can solve the problems of high temperature braking instability, low heavy metal content, and great environmental hazards, and achieve no brake squeal. , Good comfort, good resistance to high temperature thermal recession

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

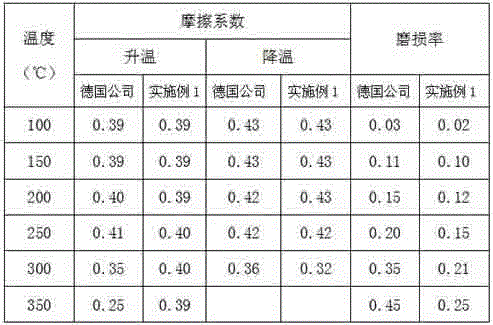

Examples

Embodiment 1

[0012] Embodiment 1: 2.5 parts by weight of aminosilane (1000 grams per part, the same below), 4 parts of calcium silicate hydrate, 5.5 parts of polyacrylonitrile fiber, 0.2 part of fused zirconia, 4 parts of aramid fiber, hemp 2.5 parts of fiber, 6 parts of expanded vermiculite, 9 parts of ceramic fiber, 3.5 parts of magnetite, 5 parts of graphene, 7.5 parts of boron phenolic resin, 5 parts of benzoxazine resin, 16 parts of calcium sulfate whisker, potassium titanate 16 parts of whiskers, 5.5 parts of flake graphite, 6 parts of cashew oil friction powder, 6 parts of calcined petroleum coke, 2 parts of boron nitride, 5 parts of flake aluminum powder, 3 parts of nano-titanium dioxide, 0.6 parts of silicon carbide, and 1 part of tantalum carbide , 2 parts of nano-zinc oxide, and 2 parts of molybdenum trioxide are poured into a high-speed disperser, stirred to form a uniformly dispersed powder friction material composition, and then the friction material composition is taken out a...

Embodiment 2

[0013] Example 2: 2 parts by weight of aminosilane, 4.55 parts of calcium silicate hydrate, 5 parts of polyacrylonitrile fiber, 0.25 part of fused zirconia, 4.5 parts of aramid fiber, 2.0 parts of hemp fiber, and 5 parts of expanded vermiculite , 10 parts of ceramic fiber, 5 parts of magnetite, 8 parts of graphene, 7.4 parts of boron phenolic resin, 3 parts of benzoxazine resin, 15 parts of calcium sulfate whisker, 17 parts of potassium titanate whisker, 6.5 parts of flake graphite , 7.5 parts of cashew nut oil friction powder, 7 parts of calcined petroleum coke, 1.5 parts of boron nitride, 7 parts of flake aluminum powder, 5 parts of nano-titanium dioxide, 0.4 part of silicon carbide, 2 parts of tantalum carbide, 1 part of nano-zinc oxide, trioxide Pour 1 part of molybdenum into a high-speed disperser, stir to form a uniformly dispersed powder friction material composition, then take out the friction material composition and put it into a forming mold for compression molding, ...

Embodiment 3

[0014] Example 3: 3 parts of aminosilane, 5.5 parts of calcium silicate hydrate, 6 parts of polyacrylonitrile fiber, 0.3 part of fused zirconia, 5 parts of aramid fiber, 2.2 parts of hemp fiber, and 5.5 parts of expanded vermiculite by weight , 8.5 parts of ceramic fiber, 4 parts of magnetite, 6 parts of graphene, 7 parts of boron phenolic resin, 4 parts of benzoxazine resin, 17 parts of calcium sulfate whisker, 18 parts of potassium titanate whisker, 7 parts of flake graphite , 8 parts of cashew nut oil friction powder, 8 parts of calcined petroleum coke, 1.8 parts of boron nitride, 6 parts of flake aluminum powder, 4.2 parts of nano-titanium dioxide, 0.5 parts of silicon carbide, 1.5 parts of tantalum carbide, 1.5 parts of nano-zinc oxide, trioxide Pour 1.5 parts of molybdenum into a high-speed disperser, stir to form a uniformly dispersed powder friction material composition, then take out the friction material composition and put it into a forming mold for compression moldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com