Actuating expanding device for automobile drum brake and drum brake

A drum brake and brake shoe technology, applied in the direction of brake parts, brake actuators, gear shifting mechanisms, etc., can solve the problem of small lift, small lift of the central drive shaft, and the brake shoes cannot be braked synchronously, etc. problems, to achieve the effect of reducing thermal recession, short braking distance, and conducive to heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

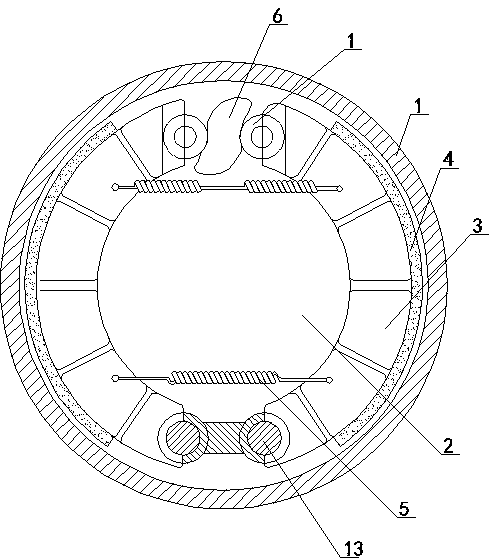

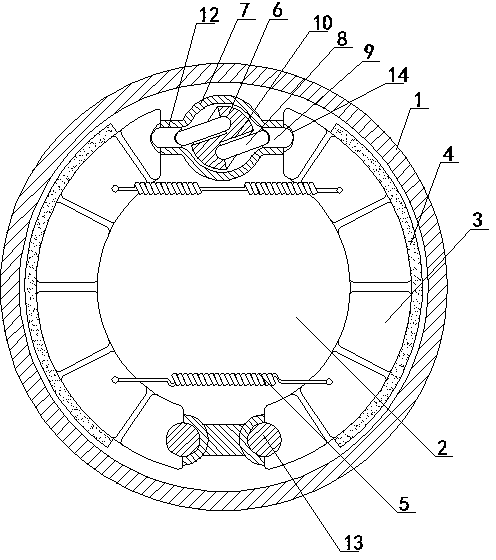

[0029] The drum brake of the present invention is mainly composed of a brake drum 1, a brake base plate 2, a brake shoe 3, a friction plate 4, a return spring 5 and an actuating opening device.

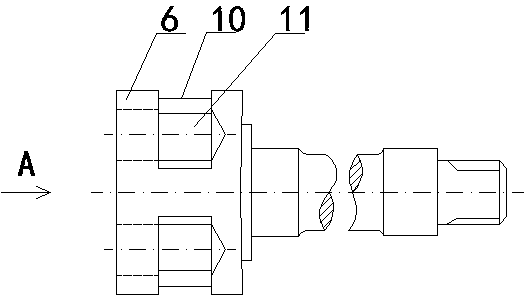

[0030] The brake drum 1 is slidingly connected with the axle of the automobile by means of rolling bearings, and the brake base plate 2 is fixedly connected with the axle of the automobile by means of connecting pieces. The lower ends of the two brake shoes 3 are respectively hinged with the brake bottom plate 2 through support pins 13 . Force-bearing arcuate surfaces 14 are respectively processed on the opposite surfaces of the top ends of the two brake shoes 3 . The axes of the two stressed arcuate surfaces 14 are on the same horizontal plane. Two friction discs 4 are respectively fixed on the outer arc surfaces of the two brake shoes 3 . The return spring 5 is fixedly connected between the two brake shoes 3 . The actuation and expansion device is arranged between the top ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com