auto adjuster

An automatic adjustment, driving shaft technology, applied in the direction of the slack adjuster, etc., can solve the problems of unstable braking clearance and small braking clearance, and achieve the effect of avoiding the accumulation of return error and stabilizing the braking clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

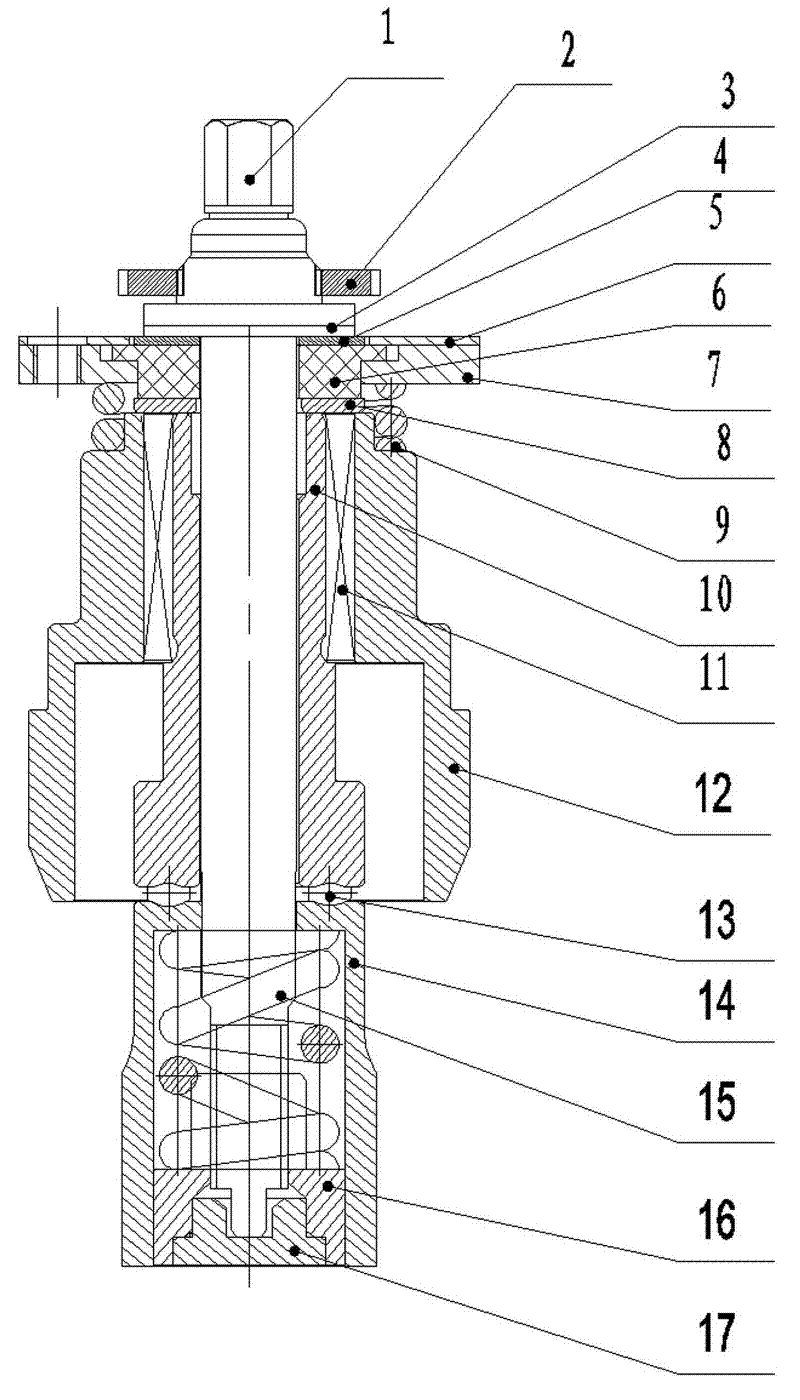

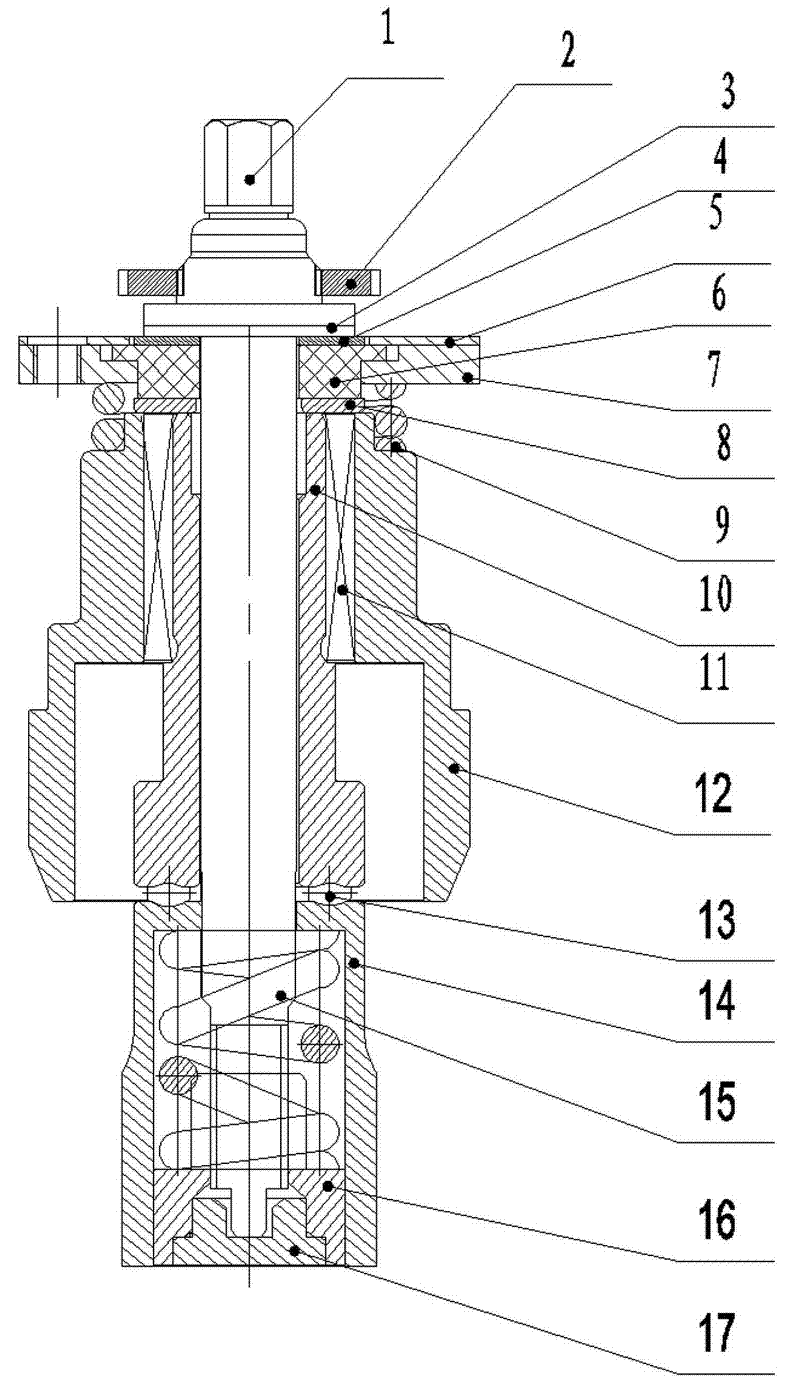

[0007] like figure 1 As shown, the present invention is further described as follows: the connecting block of the automatic adjuster is composed of an inner block 6 and an outer block 7, the friction pad is composed of an inner pad 4 and an outer pad 5, and the inner block 6 and the outer block 7 are in a clearance fit , the inner pad 4 is pressed on the inner block 6, the outer pad 5 is pressed on the outer block 7, the inner pad 4 and the outer pad 5 are radially fixed with a gap, and a gap return device is formed between the inner pad 4 and the outer pad 5 The driving shaft 1 is composed of an outer polygonal / inner polygonal head and a journal, the polygonal head is larger than the journal; the driving shaft 1 passes through the inner block 6, the inner ring 10, and protrudes from the lower end of the inner ring 10, The head is pressed on the inner block 6 through the washer 3 and the inner pad 4 of the friction pad, and the drive shaft 1 is in clearance fit with the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com