Borate type synthetic brake fluid with ultralow low-temperature viscosity and preparation method thereof

A technology of low-temperature viscosity and boric acid ester, applied in lubricating compositions, petroleum industry, etc., can solve problems such as poor compatibility between additives and base fluid, lower high-temperature air resistance of brake fluid, and cumbersome preparation process of base fluid, etc. Achieve the effects of excellent high-temperature gas resistance resistance, strong controllability of raw material purity, and efficient and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

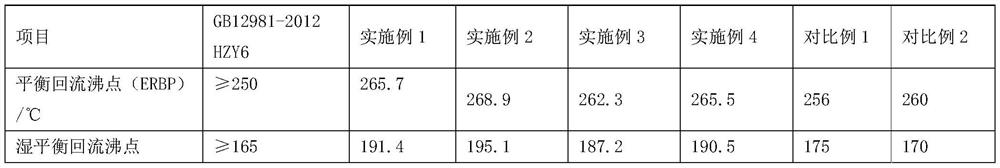

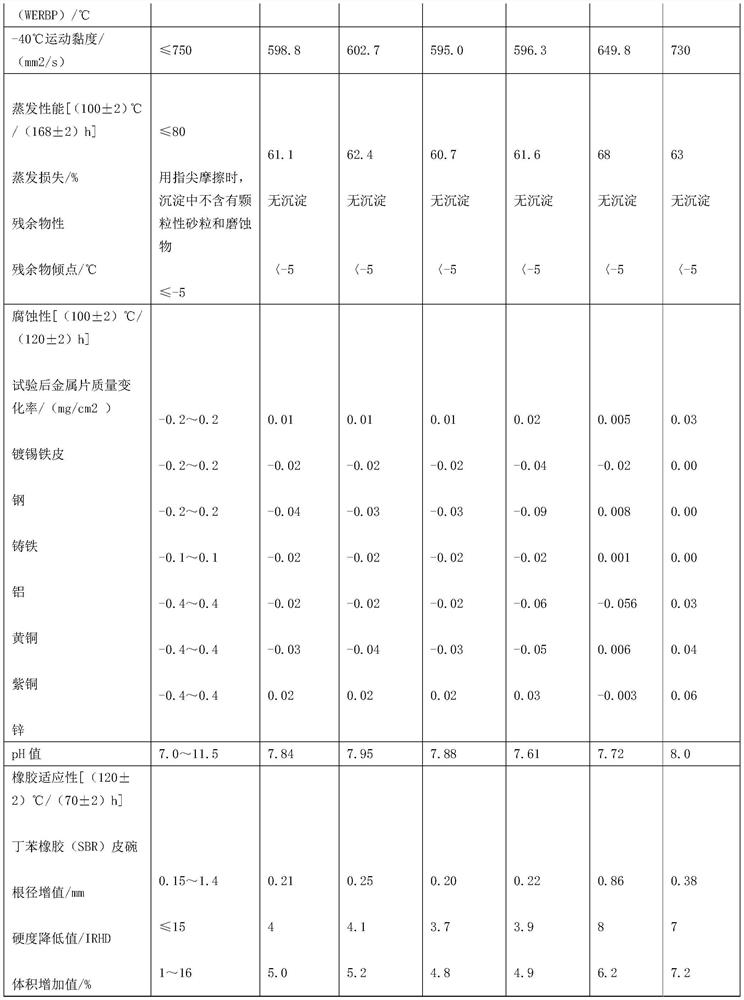

Embodiment 1

[0036] The present invention is an ultra-low temperature viscosity borate type synthetic brake fluid, which is composed of triethylene glycol monomethyl ether borate (MH-510), triethylene glycol monomethyl ether (MTG), triethylene glycol monomethyl ether Composed of butyl ether (TBG), rubber swelling inhibitor, antioxidant, corrosion inhibitor, and pH adjuster. In the ultra-low temperature viscosity borate type synthetic brake fluid, the weight percentage of the triethylene glycol monomethyl ether borate (MH-510) is 65%, and the triethylene glycol The weight percentage of monomethyl ether (MTG) is 15%, the weight percentage of described triethylene glycol monobutyl ether (TBG) is 8%, the weight percentage of described rubber swelling inhibitor is 10%, and described The weight percentage of the antioxidant is 0.6%, the weight percentage of the corrosion inhibitor is 0.4%, and the weight percentage of the pH regulator is 1.0%.

[0037] The preparation method of a kind of ultra-...

Embodiment 2

[0045] The present invention is an ultra-low temperature viscosity borate type synthetic brake fluid, which is composed of triethylene glycol monomethyl ether borate (MH-510), triethylene glycol monomethyl ether (MTG), triethylene glycol monomethyl ether Composed of butyl ether (TBG), rubber swelling inhibitor, antioxidant, corrosion inhibitor, and pH adjuster. In the ultra-low temperature viscosity borate type synthetic brake fluid, the weight percentage of the triethylene glycol monomethyl ether borate (MH-510) is 68%, and the triethylene glycol The weight percentage of monomethyl ether (MTG) is 16%, the weight percentage of described triethylene glycol monobutyl ether (TBG) is 6%, and the weight percentage of described rubber swelling inhibitor is 8%, and described The weight percentage of the antioxidant is 0.5%, the weight percentage of the corrosion inhibitor is 0.5%, and the weight percentage of the pH regulator is 1.0%.

[0046] The preparation method of a kind of ult...

Embodiment 3

[0054] The present invention is an ultra-low temperature viscosity borate type synthetic brake fluid, which is composed of triethylene glycol monomethyl ether borate (MH-510), triethylene glycol monomethyl ether (MTG), triethylene glycol monomethyl ether Composed of butyl ether (TBG), rubber swelling inhibitor, antioxidant, corrosion inhibitor, and pH adjuster. In the ultra-low temperature viscosity borate type synthetic brake fluid, the weight percentage of the triethylene glycol monomethyl ether borate (MH-510) is 62%, and the triethylene glycol The weight percentage of monomethyl ether (MTG) is 17%, the weight percentage of described triethylene glycol monobutyl ether (TBG) is 9%, the weight percentage of described rubber swelling inhibitor is 10%, and described The weight percentage of the antioxidant is 0.5%, the weight percentage of the corrosion inhibitor is 0.5%, and the weight percentage of the pH regulator is 1.0%.

[0055] The preparation method of a kind of ultra-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com