Method and device for high-capacity entrained flow gasifier

a gasifier and high-capacity technology, applied in the direction of gasifier mechanical details, combustible gas production, combustible gas purification/modification, etc., can solve the problems of high repair cost, rapid wear, and increase in wear process with increasing ash content, so as to achieve reliable and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]FIG. 1 shows a block diagram of the process steps of pneumatic metering of pulverized fuel, gasification in a gasification reactor with cooled reaction chamber structure 2, quench-cooling 3, crude gas scrubbing 4, in which there can be a waste heat boiler 4.1 between the quench-cooling 3 and the crude gas scrubbing 4, and a condensation or partial condensation 5 follows the crude gas scrubber 4.

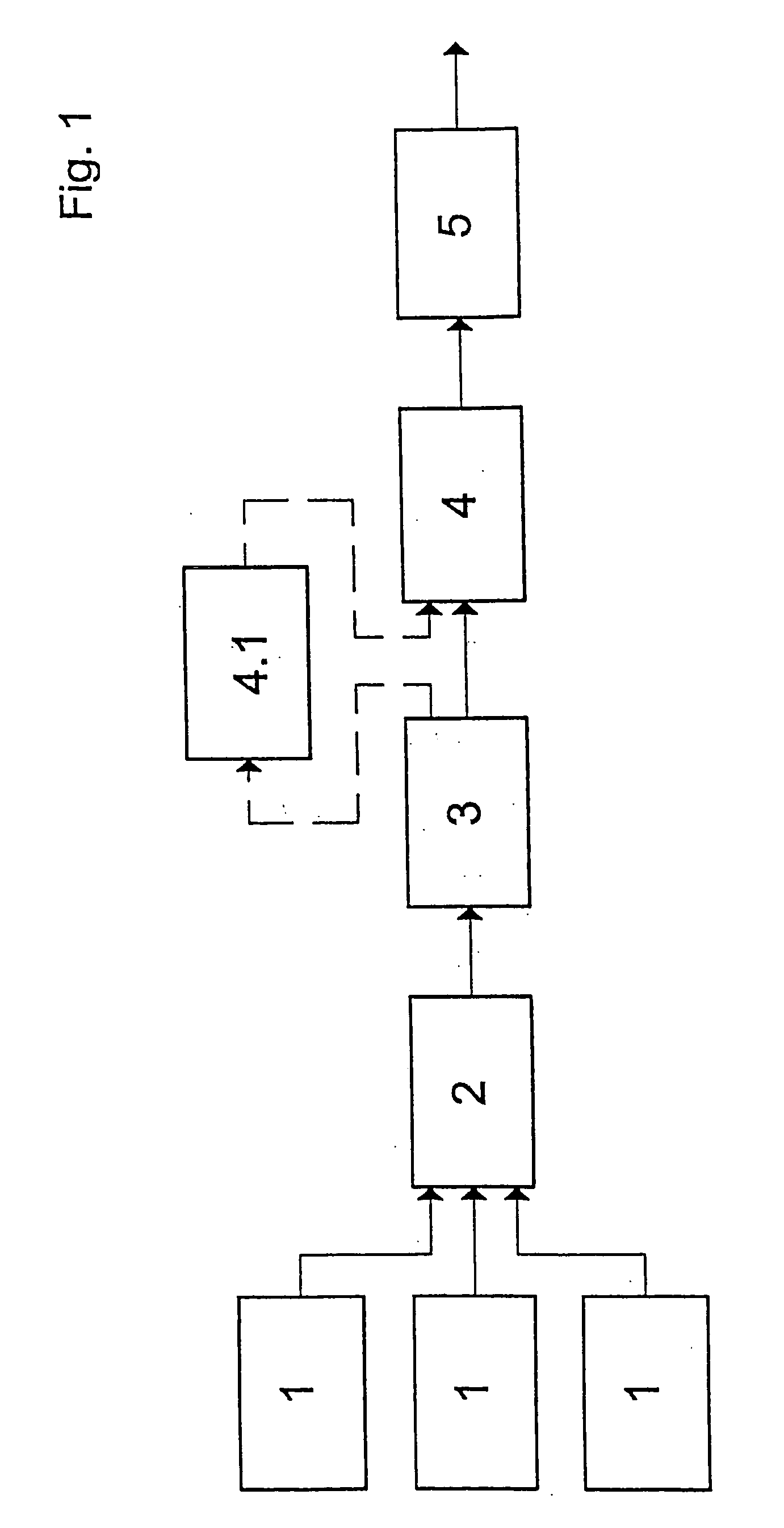

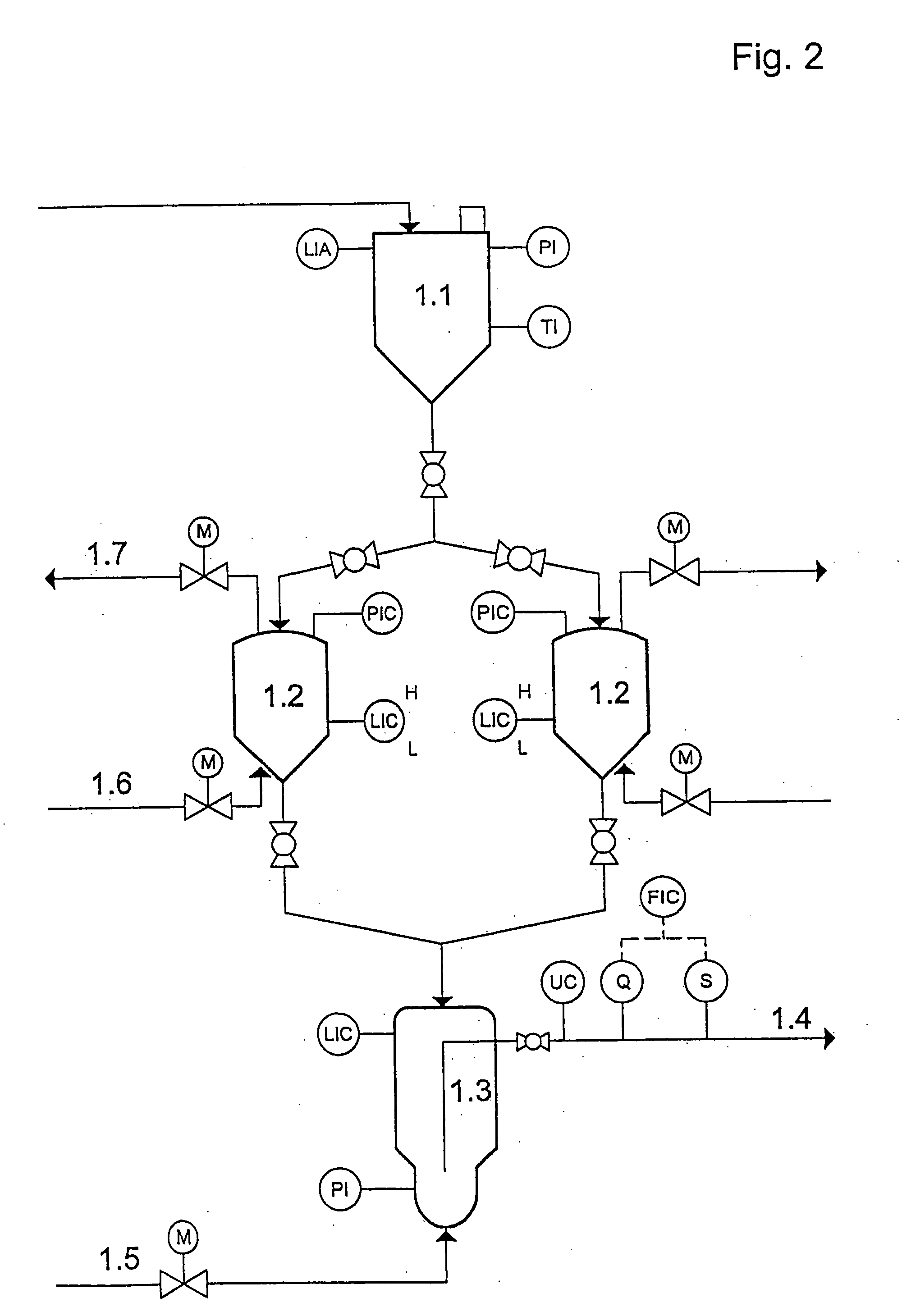

[0025]FIG. 2 shows a metering system for pulverized fuel consisting of a bunker 1.1 followed by two pressurized sluices 1.2, into which lead lines 1.6 for inert gas, and at the top of which depressurization lines 1.7 exit, with lines to the metering tank 1.3 leaving the pressurized sluices 1.2 from the bottom. There are fittings on the pressurized sluices 1.2 for monitoring and regulating. A line 1.5 for fluidizing gas leads into the metering tank from below, which provides for fluidizing the gas, and the fluidized pulverized fuel is fed through the transport line 1.4 to a gasification...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com