Preparation method of asphalt liquid phase coated modified artificial graphite lithium battery cathode material

A technology of artificial graphite and negative electrode material, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low initial efficiency and specific capacity of artificial graphite, rough surface of artificial graphite, large specific surface, etc., and is suitable for industrial scale production. , the effect of improving specific capacity and cycle stability, and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

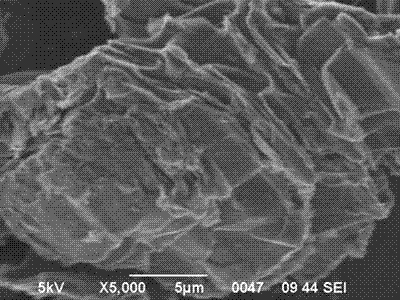

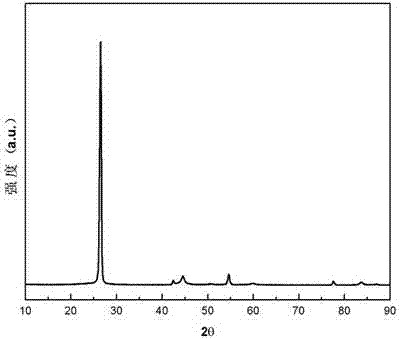

Image

Examples

Embodiment 1

[0036] (1) Preparation of lithium battery anode material of modified artificial graphite coated with asphalt liquid phase:

[0037] (1) Mechanically pulverize petroleum coke, then perform mechanical ball milling on the powder to obtain fine powder, and carry out fine powder classification;

[0038] (2) Mix the classified fine powder with an appropriate amount (5%) of asphalt powder, and then put the evenly mixed powder into a medium-temperature reactor for reaction (the temperature in the reactor is 500°C, and the stirring speed in the kettle is 40r / min, the reaction time is 8h), and finally discharged.

[0039] (3) Pass the discharged powder through the shaping and classifying machine for shaping and grading again;

[0040] (4) Carry out high-temperature graphitization treatment (2500°C for 36h) of the product obtained above, and then undergo classification treatment to obtain artificial graphite material A (D 50 =10um).

[0041] (5) Add A prepared in step 1 into ...

Embodiment 2

[0050] (1) Preparation of lithium battery anode material of modified artificial graphite coated with asphalt liquid phase:

[0051] (1) Mechanically pulverize petroleum coke, then perform mechanical ball milling on the powder to obtain fine powder, and carry out fine powder classification;

[0052] (2) Mix the classified fine powder with an appropriate amount (5%) of asphalt powder, and then put the evenly mixed powder into a medium-temperature reactor for reaction (the temperature in the reactor is 500°C, and the stirring speed in the kettle is 40r / min, the reaction time is 8h), and finally discharged.

[0053] (3) Pass the discharged powder through the shaping and classifying machine for shaping and grading again;

[0054] (4) Carry out high-temperature graphitization treatment (2500°C for 36h) of the product obtained above, and then undergo classification treatment to obtain artificial graphite material A (D 50 =10um).

[0055] (5) Add A prepared in step 1 into ...

Embodiment 3

[0063] (1) Preparation of lithium battery anode material of modified artificial graphite coated with asphalt liquid phase:

[0064] (1) Mechanically pulverize petroleum coke, then perform mechanical ball milling on the powder to obtain fine powder, and carry out fine powder classification;

[0065] (2) Mix the classified fine powder with an appropriate amount (5%) of asphalt powder, and then put the evenly mixed powder into a medium-temperature reactor for reaction (the temperature in the reactor is 500°C, and the stirring speed in the kettle is 40r / min, the reaction time is 8h), and finally discharged.

[0066] (3) Pass the discharged powder through the shaping and classifying machine for shaping and grading again;

[0067] (4) Carry out high-temperature graphitization treatment (2500°C for 36h) of the product obtained above, and then undergo classification treatment to obtain artificial graphite material A (D 50 =10um).

[0068] (5) Add A prepared in step 1 into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com