Crushing device for waste concrete regeneration preparation

A waste concrete and crushing device technology, applied in the direction of dry gas arrangement, use of liquid separation agent, lighting and heating equipment, etc., can solve the problems of wasting land resources, polluting the environment, affecting the environment, etc., and achieve the effect of improving the crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

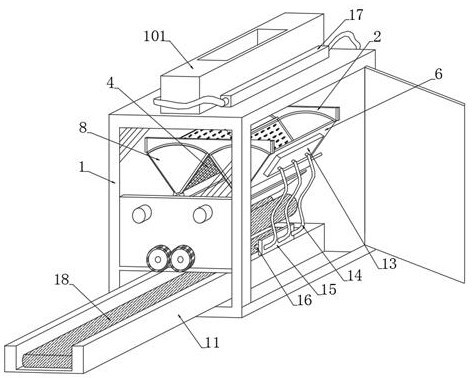

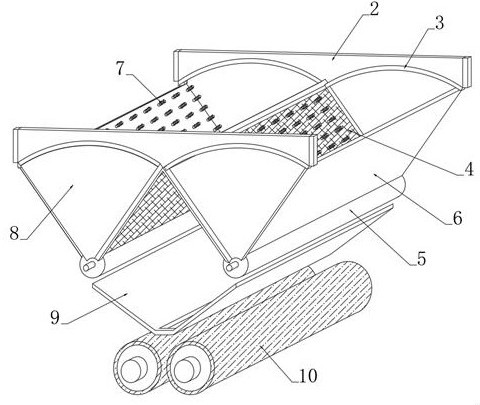

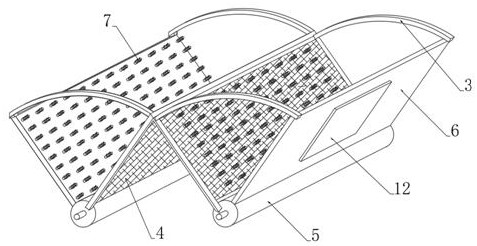

[0034] see Figure 1-2 , a crushing device for waste concrete regeneration preparation, comprising a crushing box 1 and a feed channel 101 arranged in the middle of the top of the crushing box 1, a rolling crushing mechanism is installed at the top of the crushing box 1, and the rolling crushing mechanism includes a crushing and crushing mechanism fixedly connected to The front and rear of the crushing box 1 are opposite to the special-shaped connecting plates 2 on the inner wall, and the middle position of a pair of special-shaped connecting plates 2 is provided with a steel plate passing screen 4 inclined downward, and the front and rear side walls of a pair of steel plate passing the screen 4 are fixedly connected to the In the crushing box 1, crushing crushing plates 6 are arranged on the outer sides of a pair of steel plate passing screens 4, and crushing chambers are formed between the crushing crushing plates 6 and the steel plate passing screens 4, 101 are used for intr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com