Rapid drying frame for subway door plate

A drying rack and door panel technology, applied in the field of drying racks, can solve problems such as paint deformation, and achieve the effects of fast drying speed and good drying effect.

Inactive Publication Date: 2017-09-15

安徽枫帆轨道装备有限公司

View PDF4 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In view of the shortcomings of the prior art described above, the purpose of the present invention is to provide a quick drying rack for subway door panels, which is used to solve the problem in the prior art that the paint is easily deformed by hot air drying

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach

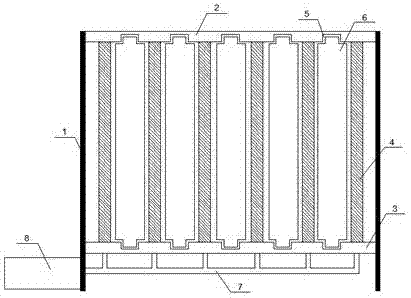

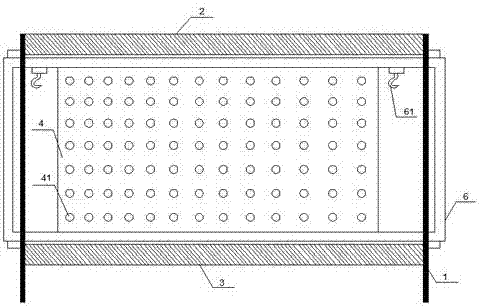

[0018] Specific implementation method: in the process of using, first extract the drying rack 6 out of a part of the chute, then hang the high-speed iron door panel on the hook 61, then return the drying rack 6 to its original position, start the exhaust fan 8, and suck through the air suction hole 41. Air, suck away the paint moisture on the high-speed iron door panel.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a rapid drying frame for a subway door plate. The rapid drying frame comprises a supporting plate, an upper bottom plate, a lower bottom plate, air suction boxes, air suction holes, sliding grooves, airing frames, hooks, an air suction pipe and an exhaust fan. The upper end and the lower end of the supporting plate are fixedly provided with the upper bottom plate and the lower bottom plate correspondingly. The six parallel air suction boxes are fixedly installed between the upper bottom plate and the lower bottom plate. The left planes and the right planes of the air suction boxes are evenly provided with the air suction holes. The corresponding positions, between every two adjacent air suction boxes, of the upper bottom plate and the lower bottom plate are provided with sliding grooves correspondingly. Every two corresponding sliding grooves are internally provided with one airing frame in a sliding mode. Each airing frame is internally provided with two hooks in a rotating mode. The air suction pipe is fixedly installed to the lower plane of the lower bottom plate. The air suction pipe is connected with an air suction opening of the exhaust fan. The rapid drying frame has the advantages of being good in drying effect and high in drying speed, not damaging product quality and the like.

Description

technical field [0001] The invention relates to a drying rack, in particular to a quick drying rack for subway door panels. Background technique [0002] In the manufacturing process of high-speed iron door panels, it is necessary to spray paint on the high-speed iron door panels. After spraying the paint, the door panels need to be dried. The traditional drying method is to stand still on the drying rack directly, but this method requires a long time. Drying time, now many manufacturers have set up a drying room to speed up the drying of the paint through hot air, but the hot air blowing on the freshly painted high-speed iron door panel is easy to deform and move the paint, making the product quality worse. Contents of the invention [0003] In view of the above-mentioned shortcomings of the prior art, the purpose of the present invention is to provide a quick drying rack for subway door panels, which is used to solve the problem in the prior art that the paint is easily ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B05D3/04

CPCB05D3/0406

Inventor 王军

Owner 安徽枫帆轨道装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com