Preparation method and preparation system for garbage and sludge mixed fuel

A mixed fuel and mixed material technology, applied in the field of solid waste resource utilization, can solve the problems of not fundamentally avoiding secondary pollution, reducing the output of secondary pollutants, and poor stability of fuel products, so as to reduce dioxin and The generation of a large amount of fly ash, high calorific value, and the effect of realizing resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

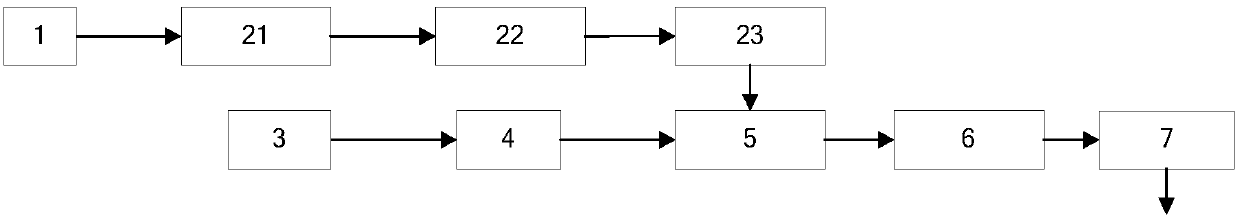

Method used

Image

Examples

Embodiment 1

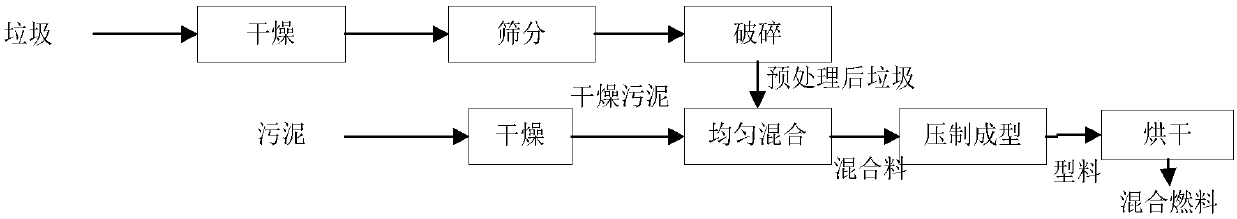

[0079] Domestic garbage and municipal sludge are placed in the garbage storage bin and the sludge storage bin for short-term storage, and then transported to the coarse crushing device and the sludge drying device through the conveyor. Among them, the moisture content of domestic garbage is 45-55 wt%, and the moisture content of municipal sludge is 70-80 wt%.

[0080] The coarse crushing device crushes domestic waste to a particle size of 80-100mm, and then transports it to the screening device through a conveyor belt for further processing. The screening device is a drum type screening machine.

[0081] The screening process screens out inorganic substances such as inorganic slag in the crushed garbage, and the screening efficiency is 80% to 90%. The inorganic slag under the screen is transported outside for treatment, and the waste on the screen is transported to the magnetic separation device for further processing.

[0082] The magnetic separation device selects the ferr...

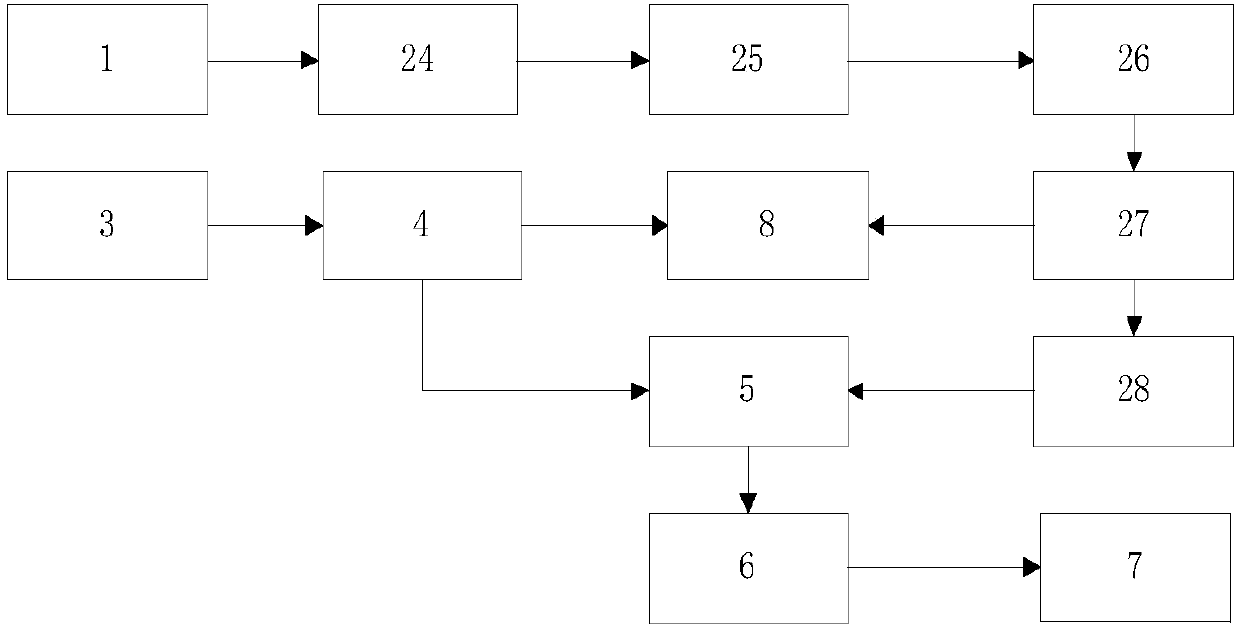

Embodiment 2

[0092] The difference between Example 2 and Example 1 is that in the process of preparing the mixture, the mass ratio of pretreated garbage to dry sludge is 1:3, and the amount of laterite nickel ore dry powder added is the same as that of dry sludge and pretreated 15% of the total mass of garbage, the mixture is extruded in a molding device to obtain a spherical fuel product, after drying, the fuel product has a moisture content of 28wt%, a particle size of 12mm, and a cold strength of 55kg / The ball has a thermal strength of 20kg / ball, and the breakage rate is 5% when dropped naturally for two meters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com