Wooden furniture production device and production method thereof

A technology for production equipment and wooden furniture, which is applied in spraying equipment, liquid spraying equipment, and equipment for coating liquid on the surface, etc. It can solve problems such as uneven distribution of board surfaces, uneven paint surfaces, and affecting production quality. Uniform thickness, easy drying and foaming, saving drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

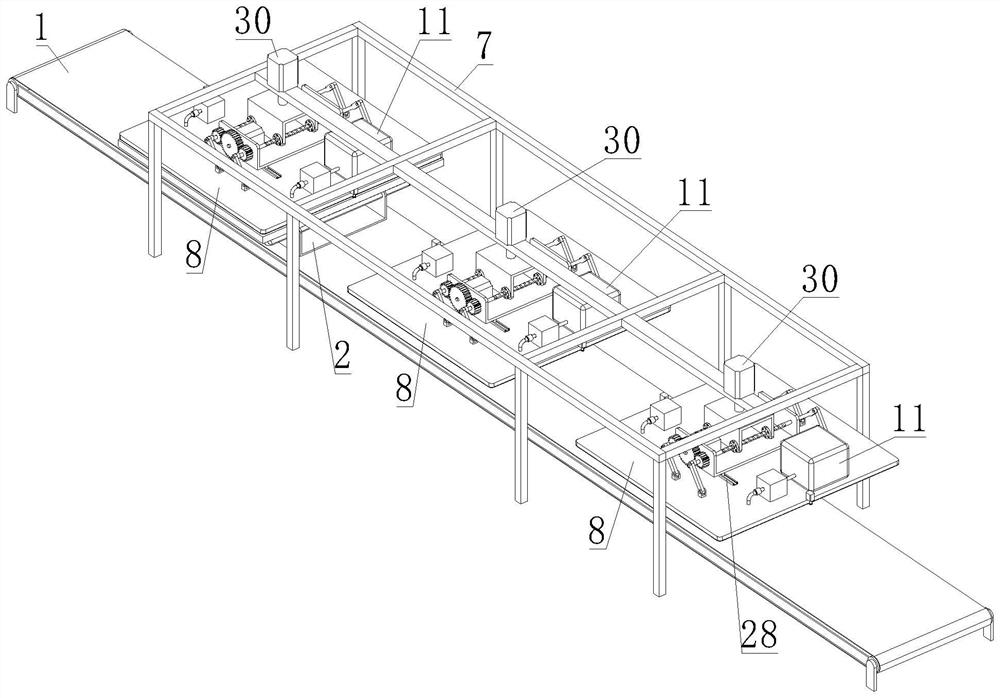

[0040] Such as figure 1 As shown, a kind of wooden furniture production device proposed by the present invention includes a frame 7, a plurality of groups of paint spraying and drying mechanisms arranged on the frame 7 in sequence, a fixing mechanism for fixing the wooden board 100, and a fixing mechanism that can drive the fixing mechanism to move sequentially. Up to the conveying mechanism 1 below the paint drying mechanism of multiple groups.

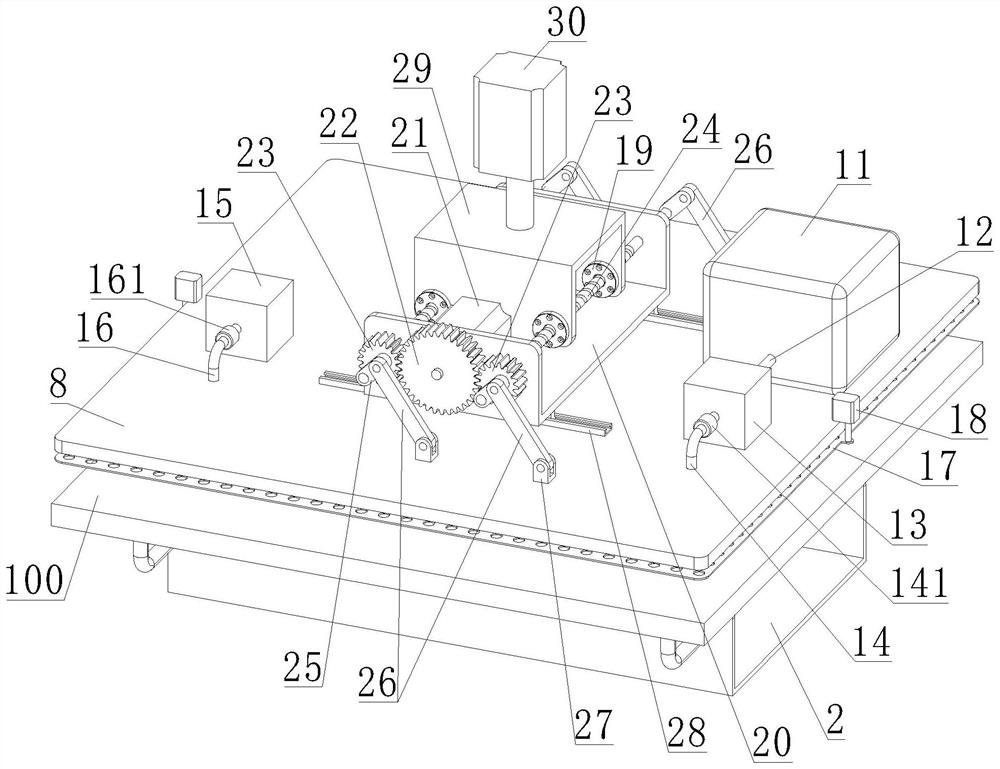

[0041] Such as figure 2 As shown, the paint drying mechanism includes a splitter box 8, an output head 9, a paint tank 11, a connecting pipe b12, a delivery pump 13, a connecting pipe c14, a hot air output device 15, a connecting pipe a16, and is used to drive the splitter box 8 in a plane. A power mechanism that moves in waves to evenly spray paint and hot air through the output head 9 and a lifting mechanism a30 for driving the power mechanism to go up and down.

[0042] Such as Figure 5-7 As shown, the array at the bottom of ...

Embodiment 2

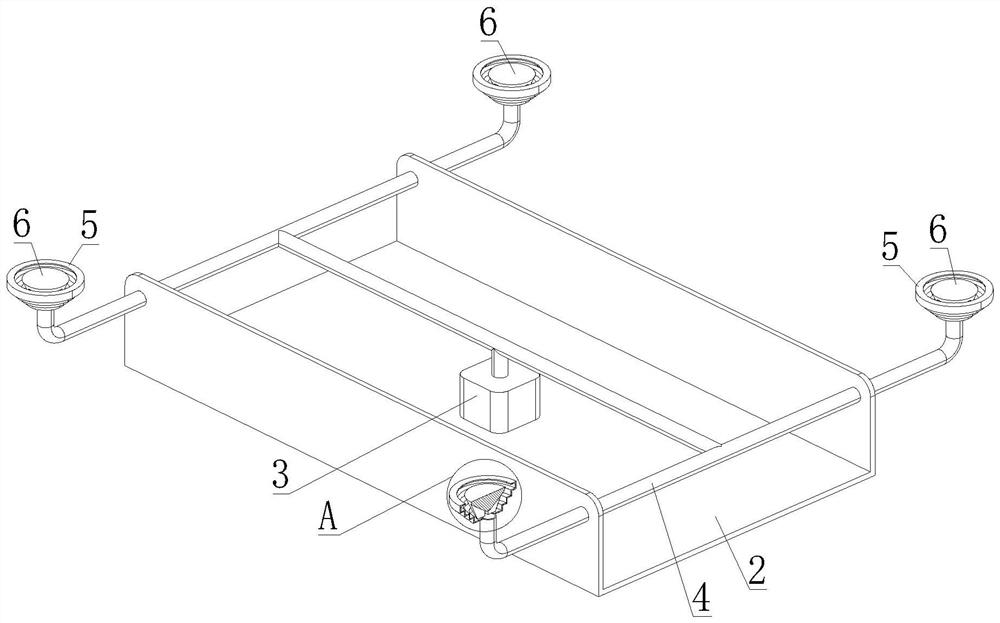

[0055] A kind of wooden furniture production device that the present invention proposes, compared with embodiment one, in this embodiment, if image 3 As shown, the fixing mechanism includes a mobile frame 2, a negative pressure device 3, a trachea 4 and a suction cup 5, the mobile frame 2 is connected with the conveying mechanism 1, the negative pressure device 3 is arranged on the mobile frame 2, the negative pressure device 3, the trachea 4 and the suction cup 5 are connected in turn, the trachea 4 has a plurality of suction ports, and a plurality of suction cups 5 are provided in total, and the suction cups 5 correspond to the suction ports one by one. The suction cup 5 is an inverted elastic tower structure, and the cross section of the suction cup 5 along the horizontal plane is circular , The top of the suction cup 5 has an inwardly folded adsorption ring part, which can increase the contact area with the wood board 100, thereby improving the reliability of adsorption. ...

Embodiment 3

[0058] A kind of wooden furniture production device that the present invention proposes, compared with embodiment one, in this embodiment, if Image 6 As shown, the output head 9 is distributed in a matrix. The output head 9 includes a contact platform and a circular platform integrally formed from top to bottom. The diameter of the bottom surface of the circular platform is smaller than the diameter of the top surface. One, so that the paint and hot air can be sprayed evenly.

[0059] Such as Figure 5 As shown, the splitter box 8 is connected with a positioning platform 10 at the discharge port 801, and the positioning platform 10 has a through hole 1001 communicated with the discharge port 801 and the main discharge channel 901. The bottom of the box 8 has a draw-in slot for the card platform 101 to snap in. The bottom of the positioning platform 10 has a circumferential slope, and the top of the contact platform has a rotating surface 903 matching the circumferential slop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com