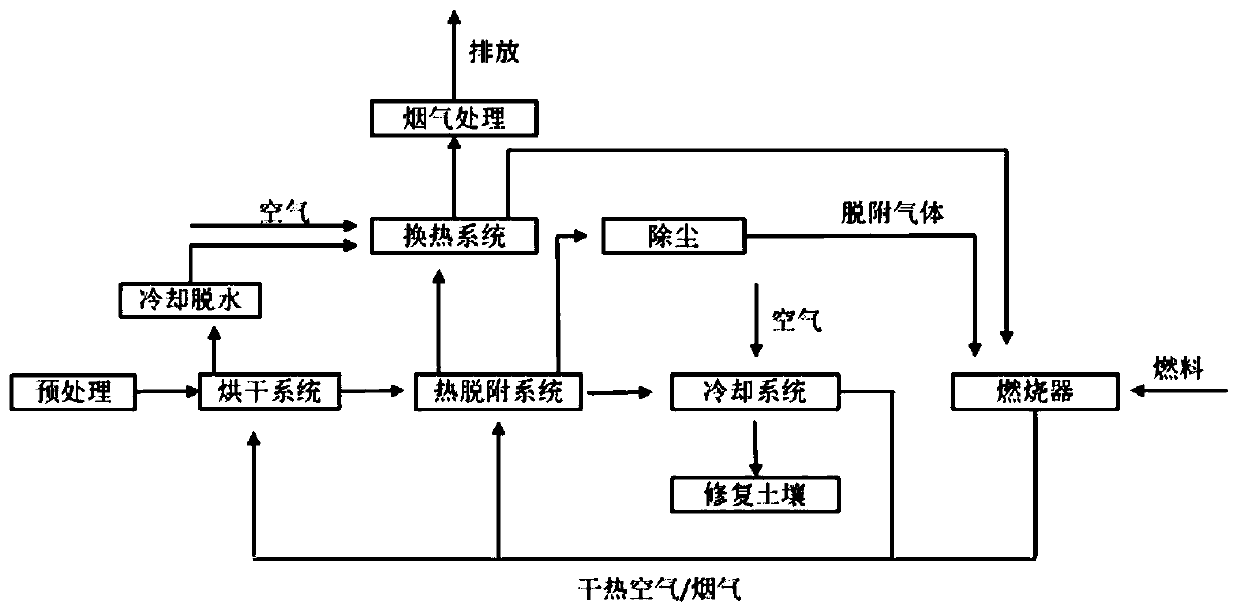

Method for treating organic contaminated soil through thermal desorption

A technology of organic pollution and thermal desorption, which is applied in the field of soil remediation of contaminated sites, can solve the problems that dioxins cannot effectively eliminate energy consumption, and achieve the effects of avoiding heat loss and waste, reducing water content, and efficient energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Select polluted soil containing an average of 785 mg / kg of polycyclic aromatic hydrocarbons. After pretreatment such as crushing and sieving, the thermal desorption temperature is controlled at 500 ° C, and the negative pressure is 1000 Pa. The anaerobic state stays in the thermal desorption furnace for 1 Hours, the flue gas from thermal desorption is burned at a high temperature of 1300°C, the content of polycyclic aromatic hydrocarbons in the treated soil is 2.8mg / kg, the removal and destruction efficiency reaches 99.6%, and the content of benzo(a)pyrene in the flue gas is 0.05μg / kg m 3 , which is less than the limit of 0.3μg / m3 in the "Comprehensive Emission Standard of Air Pollutants" 3 .

Embodiment 2

[0058] The original soil polluted by PCBs was selected. The total content of PCBs in the soil was 4374 μg / g, mainly dichlorobiphenyls, trichlorobiphenyls and tetrachlorobiphenyls, and the three accounted for 94% of the total. After pretreatments such as crushing and sieving, the temperature of thermal desorption is controlled at 550°C. Under the protection of nitrogen, the thermal desorption is carried out at normal pressure, and the residence time in the thermal desorption furnace is 50 minutes. The room temperature is 1300°C, the PCB content in the soil after treatment is 45.6μg / g, and the removal efficiency is 98.9%, which is lower than the minimum disposal standard of 50μg / g required by GB13015-91.

Embodiment 3

[0060] Dichlorvos, omethoate and parathion are the main pollutants in the polluted soil of the pesticide factory, among which the content of dichlorvos is 5.96 μg / g, omethoate 5.45 μg / g and parathion 130 μg / g, after pretreatment such as crushing and sieving , at 350°C operating pressure -500Pa, anaerobic thermal desorption of polluted soil, the flue gas from thermal desorption is burned at a high temperature of 1300°C, the desorption rates are 95.2%, 96.4%, 98.9%, respectively, and the residual dichlorvos in purified soil is 0.28μg / g, omethoate 0.20, parathion 1.43μg / g, non-methane total hydrocarbons in flue gas 32.6mg / m3, benzo(a)pyrene 0.12μg / m 3 , the residual amount of organochlorine pollutants and the emission concentration of flue gas after purification meet the limit requirements of pollutant emission standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com