Drying machine and control method thereof

A control method and technology for a drying machine, which are applied in the field of invention in terms of control methods, can solve the problems of laundry damage, drum temperature rise, and the drying process cannot be carried out normally, and achieve the effect of preventing energy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

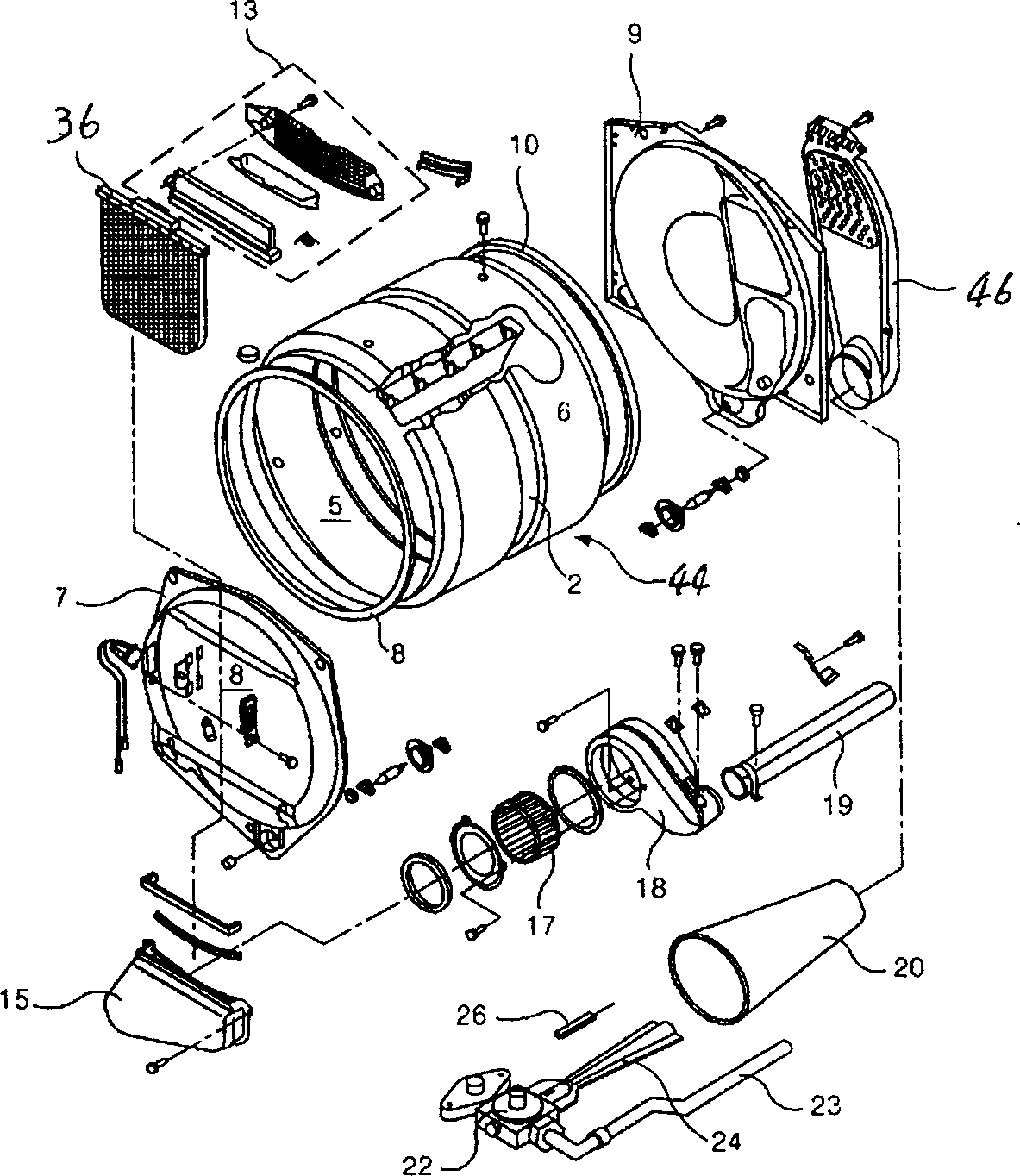

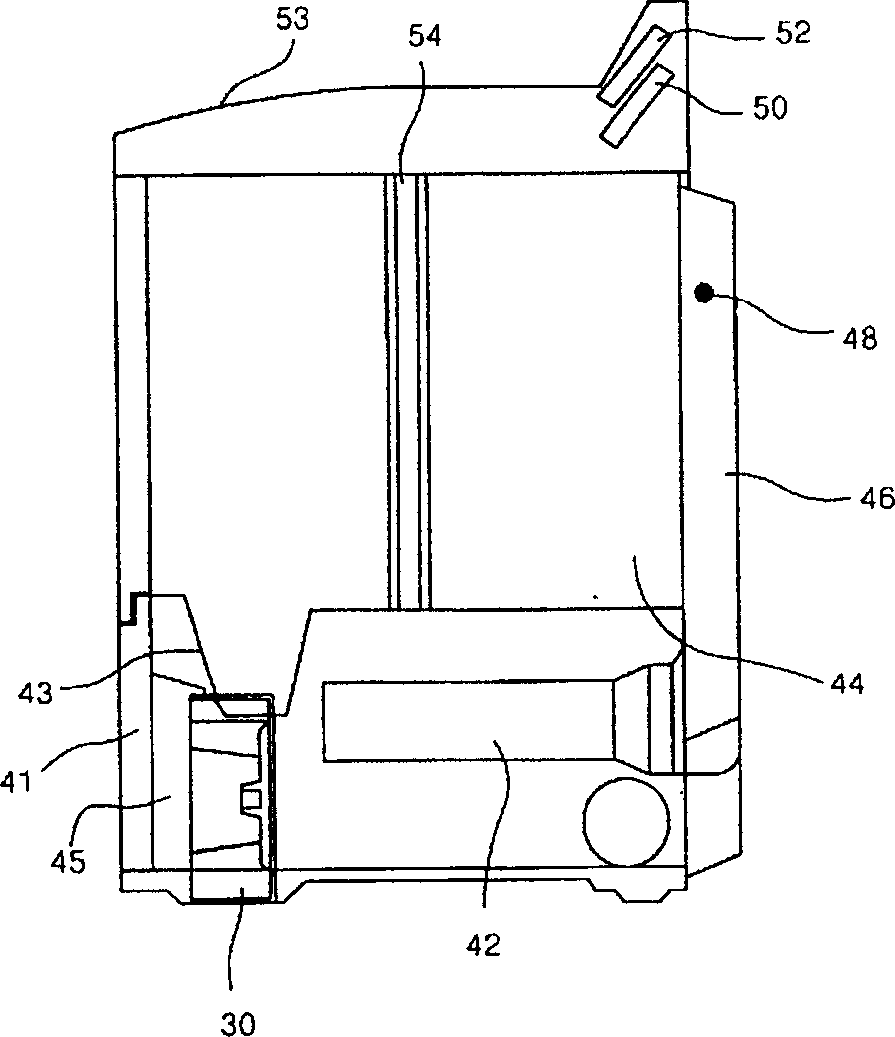

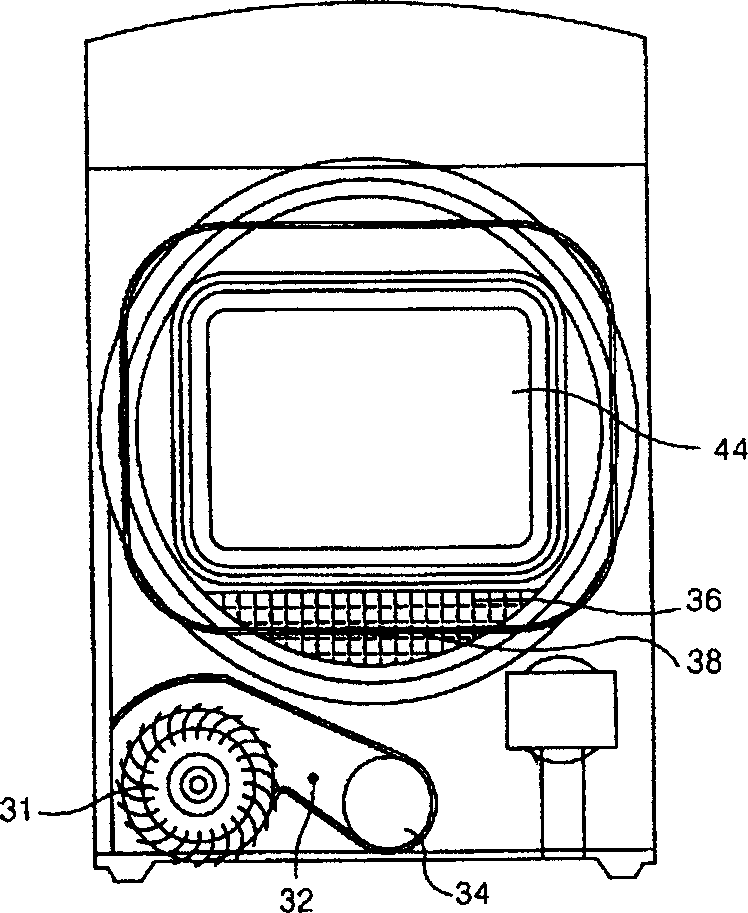

[0029] The present invention is a dryer, its structure is as shown in the figure, and the outer box body 53 is the shell of the dryer. The front panel 41 of the dryer is located at the front end of the outer box 53 . There is a rotatable drum 44 inside the outer box 53 , and the drum 44 dries the laundry put into the drum 44 . The drum 44 is rotated by a drum drive belt 54 which wraps around the outside of the drum 44 .

[0030] An exhaust port 43 is formed on the inner surface of the front panel 41 , and the exhaust port 43 opens to the inside of the drum 44 . The function of the exhaust port 43 is to discharge the air inside the drum 44 to the outside of the drum 44 . A gauze filter 36 is installed at the entrance of the exhaust port 43, and the gauze filter 36 filters foreign matter in the air.

[0031] An electrode sensor 38 is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com