Special fertilizer for preparing granular rice from sandy raw materials and preparation method and application of special fertilizer

A special fertilizer and granulation technology, which is applied in the production of granulated rice special fertilizer from sandy raw materials and its manufacturing field. It can solve the problems of calcium magnesium phosphate fertilizer not easy to granulate, inconsistent fertilizer habits, and no granulation process introduced, so as to inhibit nitrification effect, promoting photosynthesis, reducing rice lodging and pest infestation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

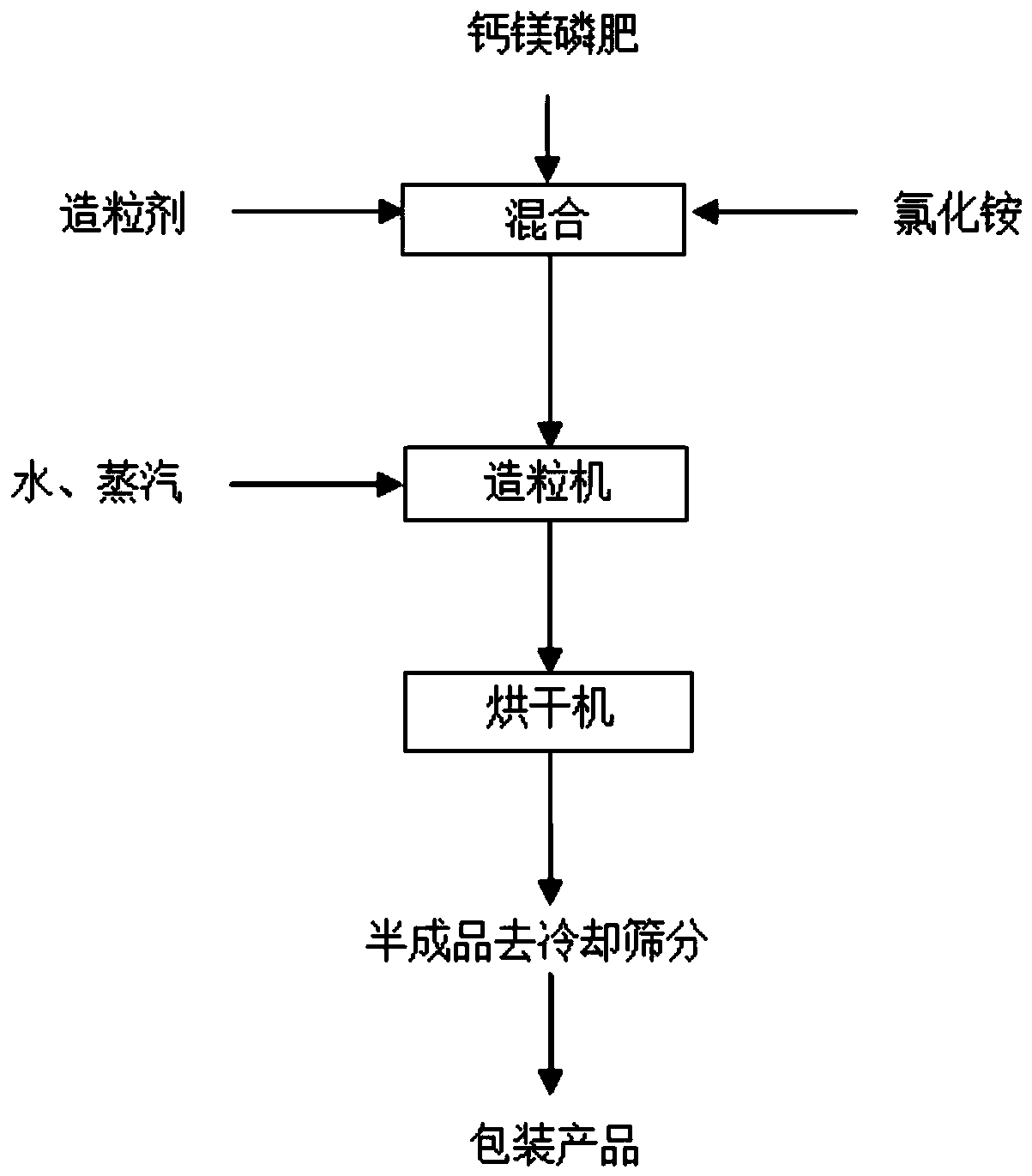

[0027] The specific process flow chart is as figure 1 As shown, take 55 parts of powdered calcium magnesium phosphate fertilizer, add 40 parts of powdered ammonium chloride, add 5 parts of bentonite, mix and add to the disc granulator together. After 10 minutes of granulation, transfer to a tumble dryer with a drying temperature of 160° C. and a drying time of 35 minutes. Then transfer to the cooling and screening machine, the cooling and screening time is 10 minutes, the finished product rate is about 80%, which is much higher than 60% of other processes, and the special fertilizer product for granular rice is obtained after packaging. 0. After applying the soil, the yield of rice increased by 18% per mu.

Embodiment 2

[0029] Take 66 parts of powdered calcium magnesium phosphate fertilizer, add 32 parts of powdered ammonium chloride, add 2 parts of kaolin, mix them and add them to a biaxial granulator. After 3 minutes of granulation, transfer to a belt dryer with a drying temperature of 200°C and a drying time of 25 minutes. Go to the cooling and screening machine again, cooling and screening time is 25 minutes, fine powder returns, the finished product yield is about 85%, higher than 60% of other processes, promptly get the granular rice special fertilizer product after packaging, the specification of this compound fertilizer N-P-K= 8-12-0. After applying the soil, the yield of rice increased by 22% per mu.

Embodiment 3

[0031] Take 30 parts of powdered calcium magnesium phosphate fertilizer, add 60 parts of powdered ammonium chloride, add 10 parts of attapulgite, mix them and add them to the drum granulator. After 5 minutes of granulation, transfer to a tumble dryer with a drying temperature of 300°C and a drying time of 20 minutes. Then transfer to the cooling and screening machine, cooling and screening time is 30 minutes, fine powder returns, the yield of finished product is about 75%, higher than 60% of other processes, and the special fertilizer product for granular rice is obtained after packaging, and the specification of this compound fertilizer is N-P-K= 15-5-0. After applying the soil, the yield of rice increased by 20% per mu.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com