Cool breathable latex product and preparation method thereof

A latex product, cool feeling technology, applied in other seating furniture, coatings, bedspreads, etc., can solve the problems of affecting the use effect of the sponge, poor air permeability of the sponge, and stuffy sponge, etc., to achieve excellent cooling effect, easy to dry , the effect of loose structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. A kind of coating adhesive is prepared, wherein the phase-change microcapsule emulsion accounts for 50% and the water-based polyurethane resin accounts for 50% by weight. Add 0.5% thickener and 0.15% green water-based color paste as color toning, run a high-speed dispersing mixer at 1000r / min for 10min, mix evenly, and make a coating glue;

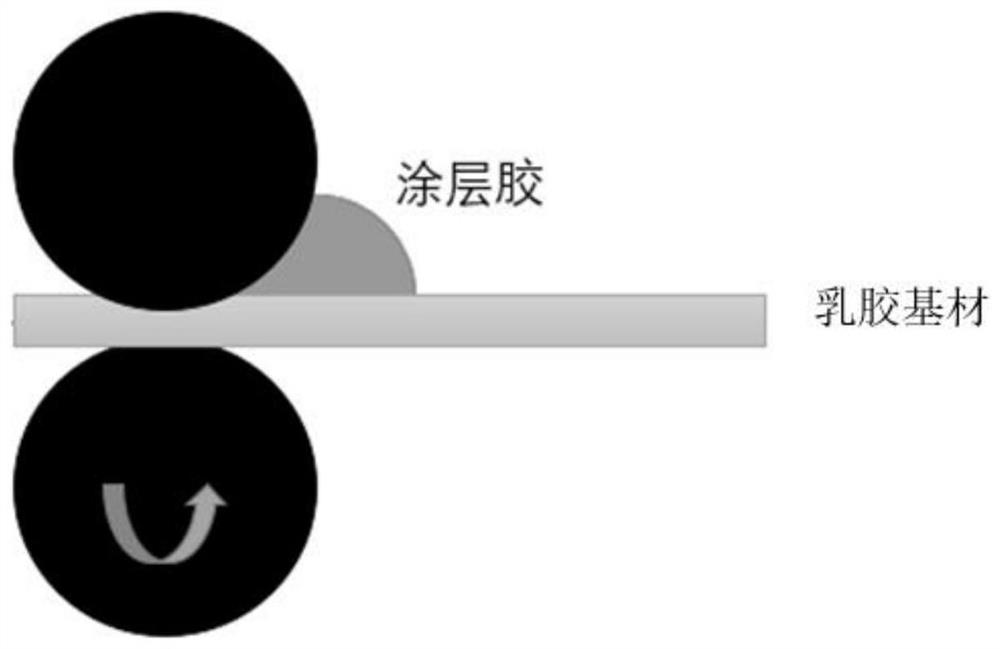

[0029] 2. Use a roller coater to evenly coat the above-mentioned coating glue on the surface of the latex pillow at a constant speed. The specific process is as follows: figure 1 ;

[0030] 3. Quickly place the coated latex pillow in a blast oven at 90°C for about 20 minutes;

[0031] 4. Take out the coated latex pillow from the oven to obtain a cool and breathable latex pillow.

Embodiment 2

[0033] 1. A kind of coating adhesive is prepared, wherein the phase-change microcapsule emulsion accounts for 50% and the water-based polyurethane resin accounts for 50% by weight. Then add 1% thickener and 0.2% green water-based color paste as color toning, run a high-speed dispersing mixer at 800r / min for 10min, mix evenly, and make a coating glue;

[0034] 2. Add 3% foaming agent and 3% foam stabilizer by weight to the above coating glue, and foam 3 times;

[0035] 3. After the coating glue foam is stable and uniform, use a roller coater to evenly coat the foamed coating glue on the surface of the latex pad at a constant speed. The specific process is as follows: figure 1 ;

[0036] 4. Quickly place the coated latex pad in a blast oven at 110°C to dry for about 10 minutes;

[0037] 5. Take out the coated latex pad from the oven to obtain a cool and breathable latex pad.

Embodiment 3

[0039] 1. A kind of coating adhesive is prepared, wherein the phase-change microcapsule emulsion accounts for 75% and the water-based polyurethane resin accounts for 25% by weight. Then add 0.5% thickener and 0.15% green water-based color paste as color toning, run a high-speed dispersing mixer at 2000r / min for 10 minutes, mix evenly, and make a coating glue;

[0040] 2. Add 0.5% foaming agent and 3% foam stabilizer by weight to the above coating glue, and foam twice;

[0041] 3. After the coating glue foam is stable and uniform, use a roller coater to evenly coat the foamed coating glue on the surface of the latex pad at a constant speed. The specific process is as follows: figure 1 ;

[0042] 4. Quickly place the coated latex pad in a blast oven at 120°C to dry for about 5 minutes;

[0043] 5. Take out the coated latex pad from the oven to obtain a cool and breathable latex pad.

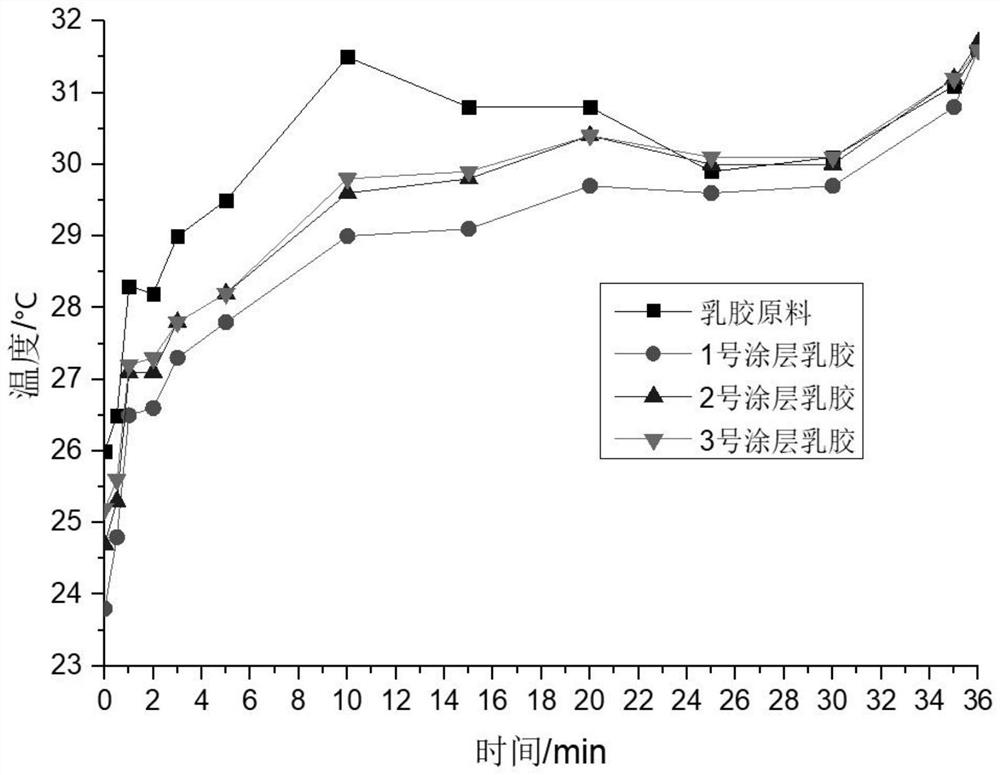

[0044]The finished product prepared by above-mentioned embodiment 1-3 has been carried out a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com