Drying device for pesticide preparation and pesticide production device

A technology for drying equipment and pesticide preparations, which is applied in drying, drying machines, lighting and heating equipment, etc., which can solve the problems of poor drying effect and insufficient mixing and stirring of raw materials, so as to prevent poor drying effect , Simple structure, easy to manufacture and assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

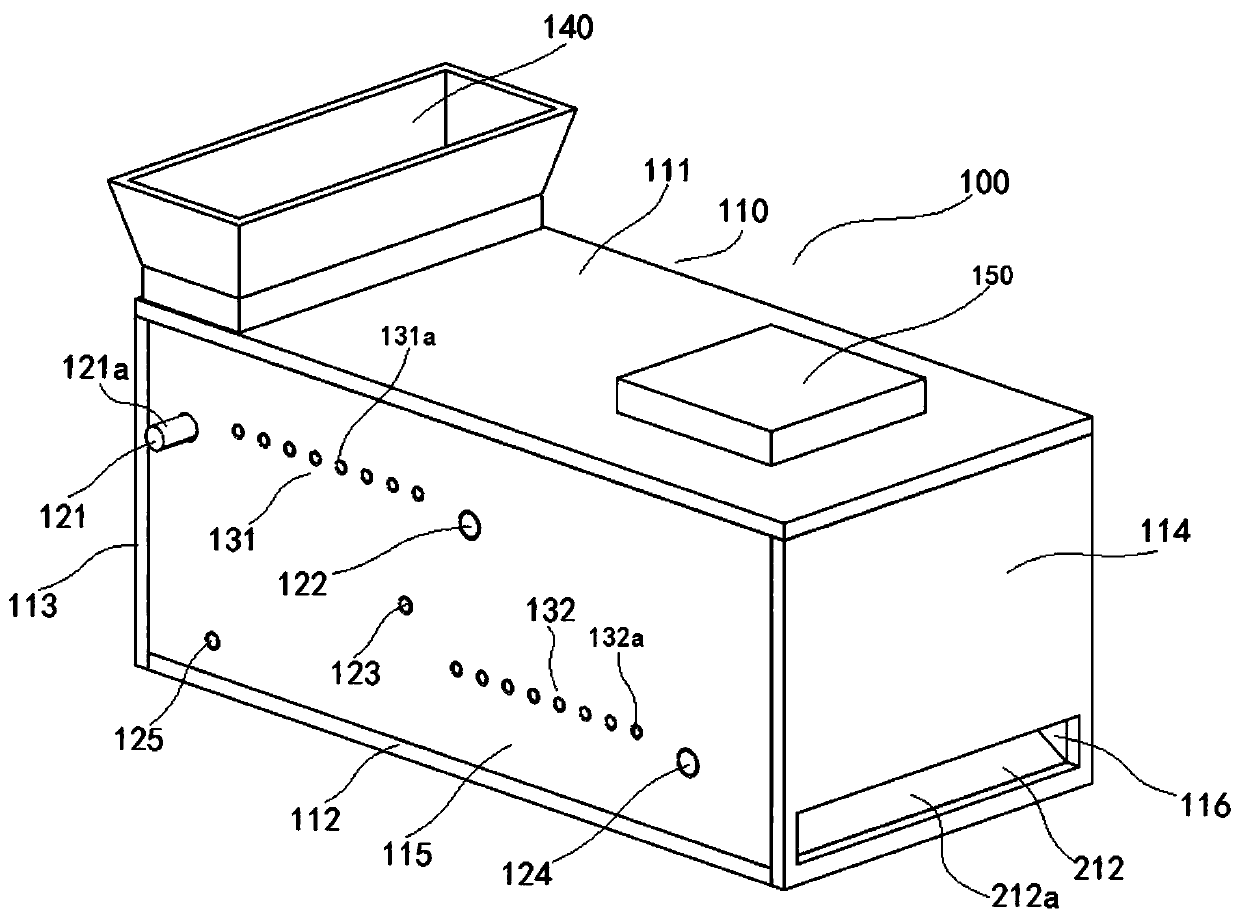

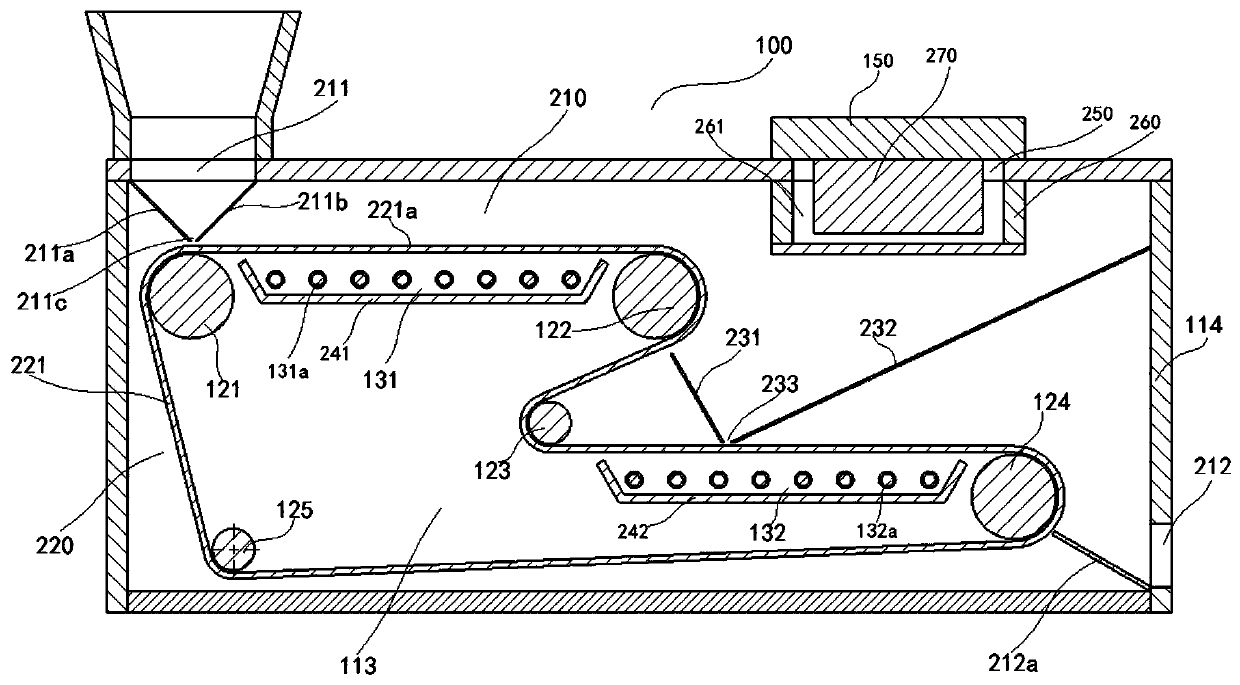

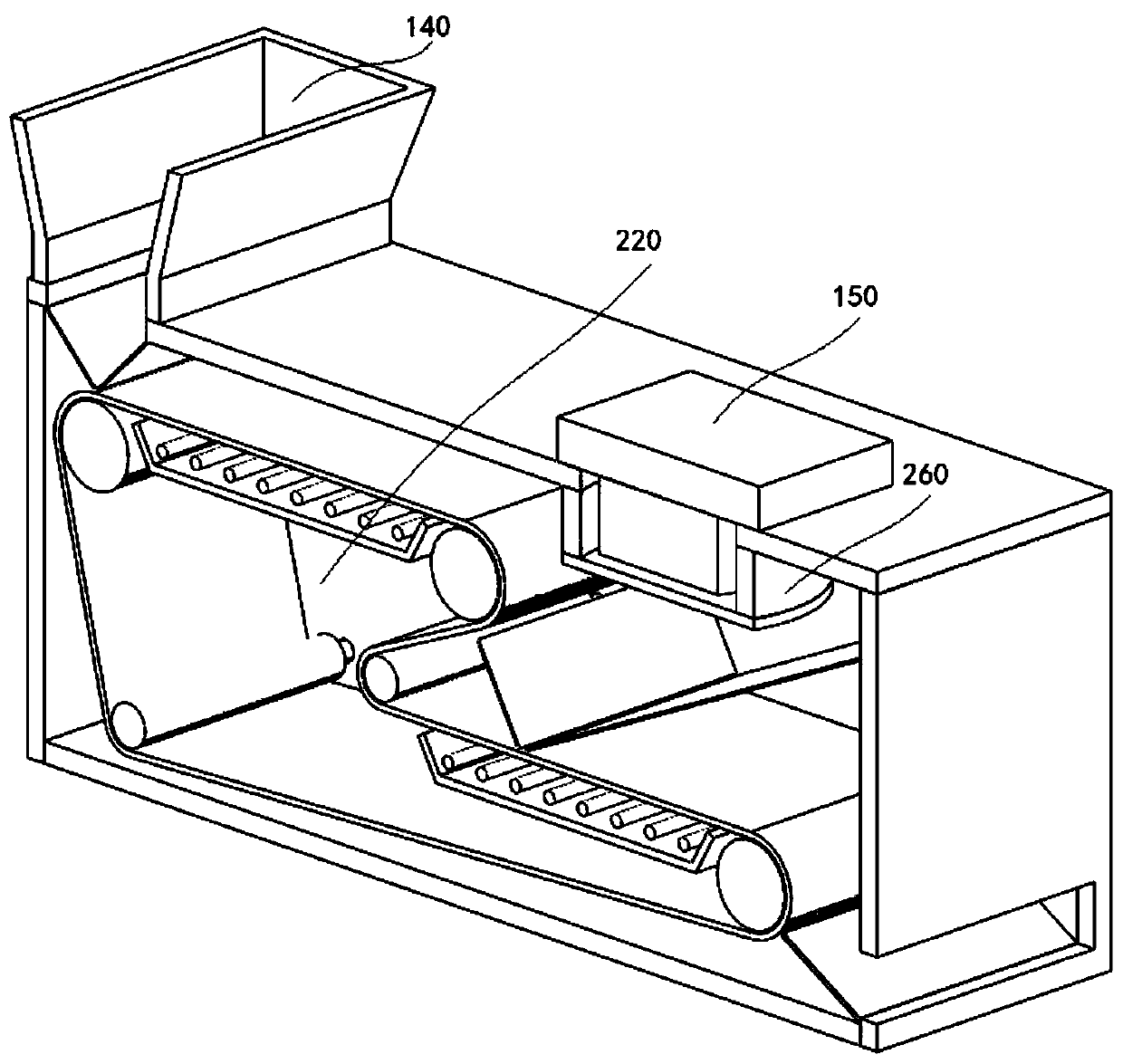

[0043] like Figure 1-3 As shown, this embodiment provides a drying device for pesticide formulations. It includes a drying device body 100, the drying device body 100 includes a cuboid-shaped drying box 110, and a drying cavity 210 is arranged in the drying box 110; The feeding port 211 and the discharging port 212, and the drying chamber 210 is provided with a drying device 220 between the feeding port 211 and the discharging port 212;

[0044] The drying device 220 includes a transmission mechanism and a conveyor belt 221. The transmission mechanism is used to drive the conveyor belt 221 to rotate cyclically. The conveyor belt 221 is used to transport the materials to be dried entering from the feeding port 211 to the discharging port 212; The drive roller 121, the first driven roller 122, the first tension roller 123, the second driven roller 124 and the second tension roller 125 are arranged in sequence in the running direction of the conveyor belt 221. The drive roller ...

Embodiment 2

[0076] A stirring device for pesticide production, such as Figure 8-Figure 14 As shown, it includes a cylindrical outer casing 1, the outer casing 1 includes an upper top plate 2, an annular side plate 3 and a funnel-shaped lower bottom plate 4, and the outer surface of the lower bottom plate 4 is provided with a downwardly extending cylindrical The discharge pipe 5 is fixed on the inner surface of the lower bottom plate 4 with a cylindrical feeding pipe 6 extending upward. There is a sealing valve 7 whose upper end surface can be inserted into the lower end surface of the feeding pipe 6. The side walls of the upper and lower ends of the feeding pipe 6 are respectively provided with a plurality of feeding pipe outlets 42 and feeding pipe inlets 41 that are evenly arranged around the axis of the feeding pipe 6. ;

[0077] The upper top plate 2 is provided with a rotating shaft 8 that extends into the feeding pipe 6 and is coaxially arranged with the feeding pipe 6 , and a sle...

Embodiment 3

[0094] like Figure 15 As shown, this embodiment provides a pesticide production equipment, which includes a stirring device, a drying device and a filling device. Wherein, the stirring device adopts the stirring device in Example 2, and the drying device adopts the drying device in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com