Belt-type fermented material sheeting and loading all-in-one machine

A fermented material and integrated machine technology, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., to achieve the effects of fast heating, fast water evaporation, and clean and environmentally friendly production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

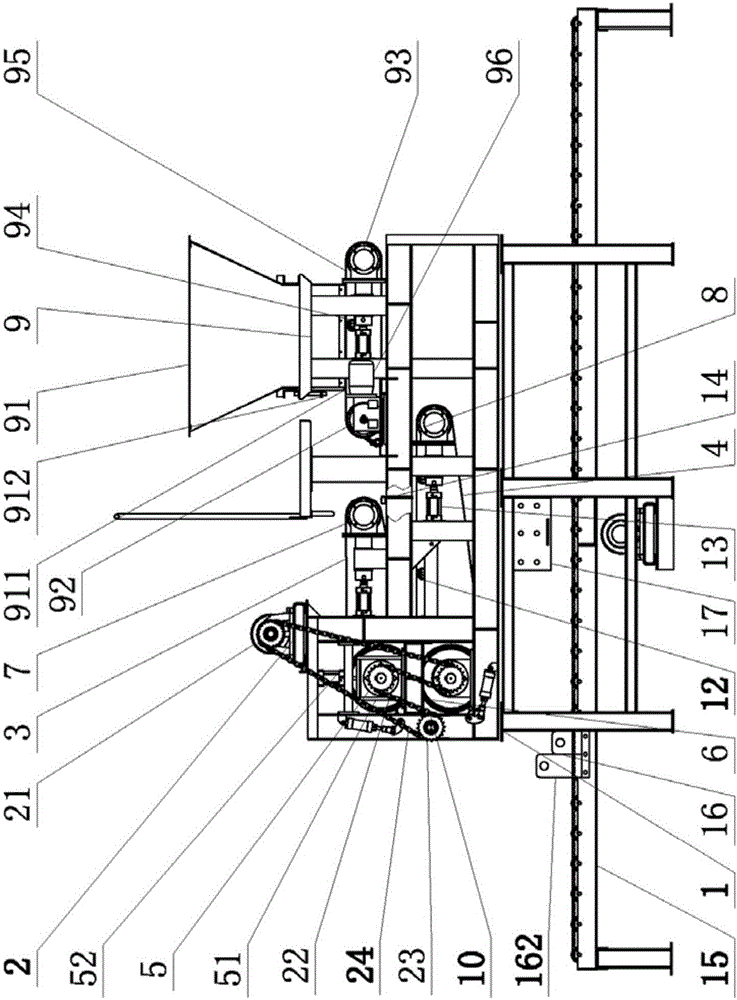

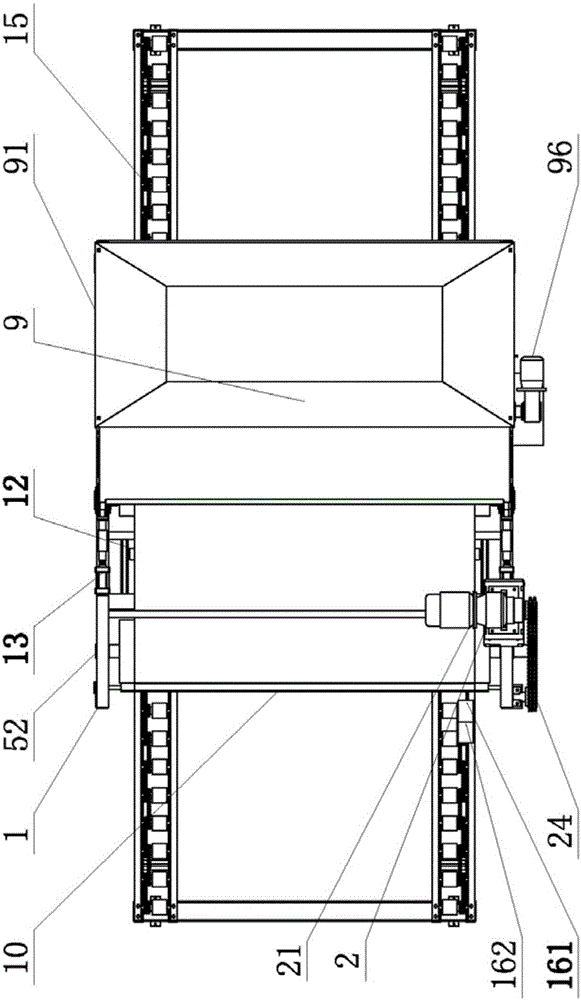

[0054] Such as Figure 1 to Figure 4 As shown, the belt-type fermented material tableting and loading integrated machine of Embodiment 1 of the present invention is mainly composed of a frame 1, a driving device 2, an upper pressing belt 3, a lower pressing belt 4, an upper pressing belt driving roller 5, and a lower pressing belt. Binder belt drive roller 6, upper binder belt reversing roller 7, lower binder belt reversing roller 8, material distributing device 9, discharge scraper 10, dish delivery device 15, sensor 16 and controller 17 constitute. Driving device 2, upper pressing belt driving roller 5, lower pressing belt driving roller 6, upper pressing belt redirecting roller 7, lower pressing belt redirecting roller 8, material distribution device 9, unloading scraper 10, feeding tray The device 15 , the sensor 16 and the controller 17 are all mounted on the frame 1 . The driving device 2 is in transmission connection with the upper pressing belt driving roller 5 and th...

Embodiment 2

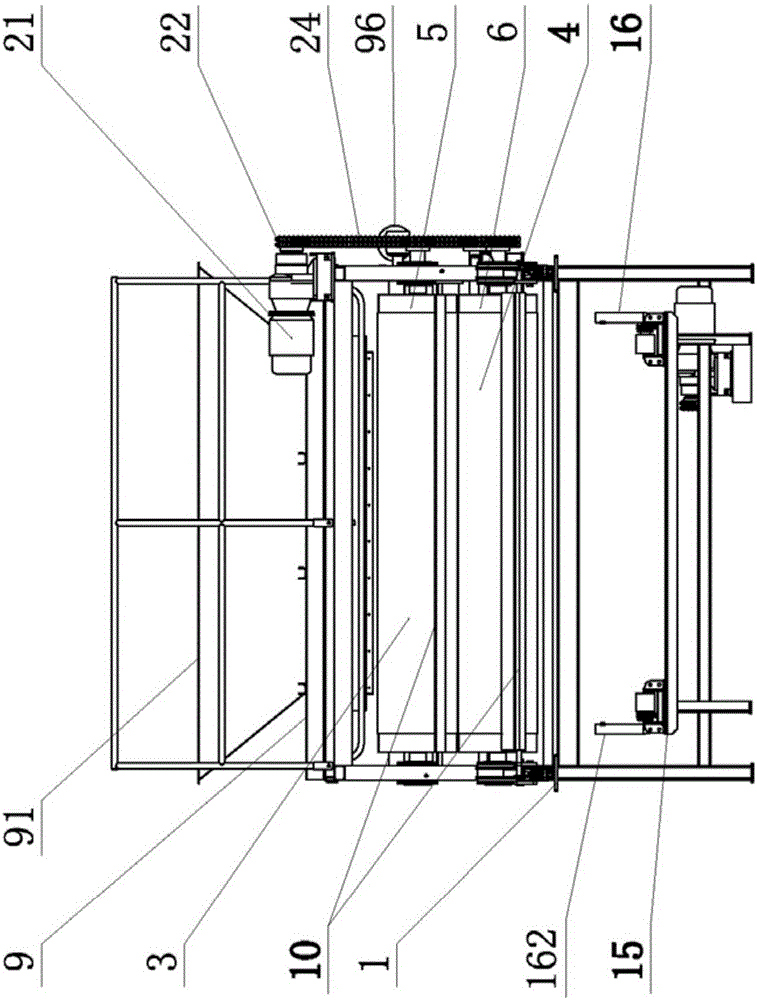

[0070] Such as Figure 5 to Figure 8 As shown, Embodiment 2 of the present invention is similar to Embodiment 1. On the basis of Embodiment 1, the lower pressing belt driving roller 6 is designed to be on the same vertical line as the upper pressing belt driving roller 5. The outer side is translated, and the positions of other rollers remain unchanged, and the length of the lower pressing belt 4 is lengthened, and then a lower pressing belt power idler 18 with the same diameter as its diameter is installed at the position of the original lower pressing belt drive roller 6. A transmission sprocket 22 is connected and installed on the mandrel of the binder belt power idler 18. The transmission sprocket 22 is a double row sprocket. The transmission sprocket 22 is connected to the transmission sprocket 22 on the drive motor 21 through a transmission chain 24. Carry out meshing transmission, carry out meshing transmission by another transmission chain 24 and the transmission sproc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com