Baking oven and baking method

A technology of oven and drying chamber, applied in the field of oven and baking, which can solve the problems of lack of humidity control function and poor drying effect, and achieve the effect of rapid internal air circulation, high drying efficiency, and not easy to deteriorate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

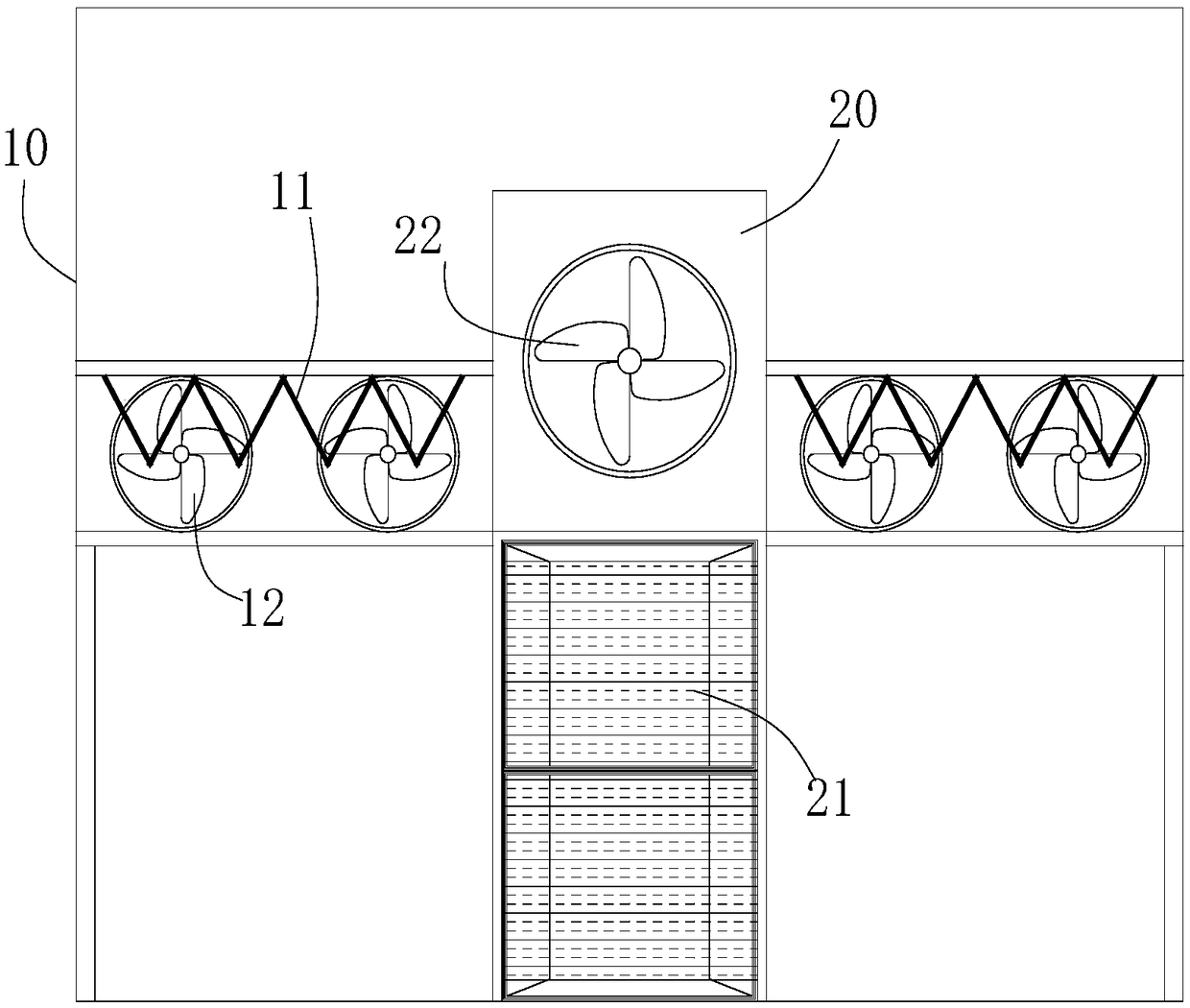

[0030] refer to figure 1 , an oven, comprising an oven shell 10 and a heat pump device;

[0031] The oven housing 10 is provided with a drying chamber with an air inlet and an air outlet; several heaters 11 are installed in the drying chamber, and several heaters 11 are installed on the oven housing 10 to discharge the humidity in the drying chamber. Gas exhaust fan 12;

[0032] The heat pump device includes a heat pump housing 20, and a compressor, an evaporator, a condenser 21, an expansion valve, and a heat pump main fan 22 respectively arranged in the heat pump housing 20; the compressor, evaporator, condenser 21, The expansion valves are connected in sequence to jointly form a refrigerant circulation processing circuit; an air duct is also provided in the heat pump casing 20, and the air inlet of the air duct communicates with the air outlet of the drying chamber, and the air outlet of the air duct communicates with the air outlet of the drying chamber. It communicates ...

Embodiment 2

[0041] A kind of roasting method, comprises the following steps:

[0042] Equipment preparation step: provide the oven as described in Example 1;

[0043] Baking steps: Put the jerky into the drying room, and turn on the heater and heat pump device for rapid heating; during the heating process, when the temperature in the drying room is detected to reach 60°C, stop the heater for heating, and when the temperature in the drying room is detected When the temperature is lower than 60°C, turn on the heater to continue heating; control the roasting time of the jerky in the drying chamber to 600 minutes to complete the roasting process.

[0044]In the baking step, a dehumidification step is also included: when the humidity sensor detects that the humidity in the drying room reaches 60%, the central processing unit controls the exhaust fan to discharge moisture until the humidity in the drying room reaches 20%; When the sensor detects that the humidity in the drying room reaches 60%...

Embodiment 3

[0047] A kind of roasting method, comprises the following steps:

[0048] Equipment preparation step: provide the oven as described in Example 1;

[0049] Baking steps: Put the jerky into the drying room, and turn on the heater and heat pump device for rapid heating; during the heating process, when the temperature in the drying room is detected to reach 60°C, stop the heater for heating, and when the temperature in the drying room is detected When the temperature is lower than 60°C, turn on the heater to continue heating; control the roasting time of the jerky in the drying chamber to 550 minutes to complete the roasting process.

[0050] In the baking step, a dehumidification step is also included: when the humidity sensor detects that the humidity in the drying room reaches 55%, the central processing unit controls the exhaust fan to discharge moisture until the humidity in the drying room reaches 25%; When the sensor detects that the humidity in the drying room reaches 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com