Low-temperature heat-insulation gas cylinder vacuumizing system

A vacuum pumping system, low temperature insulation technology, applied in fixed capacity gas storage tanks, gas/liquid distribution and storage, pressure vessels, etc., can solve the problems of long time, large area, small gas cylinder interlayer height, etc. Small, high efficiency, clean displacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

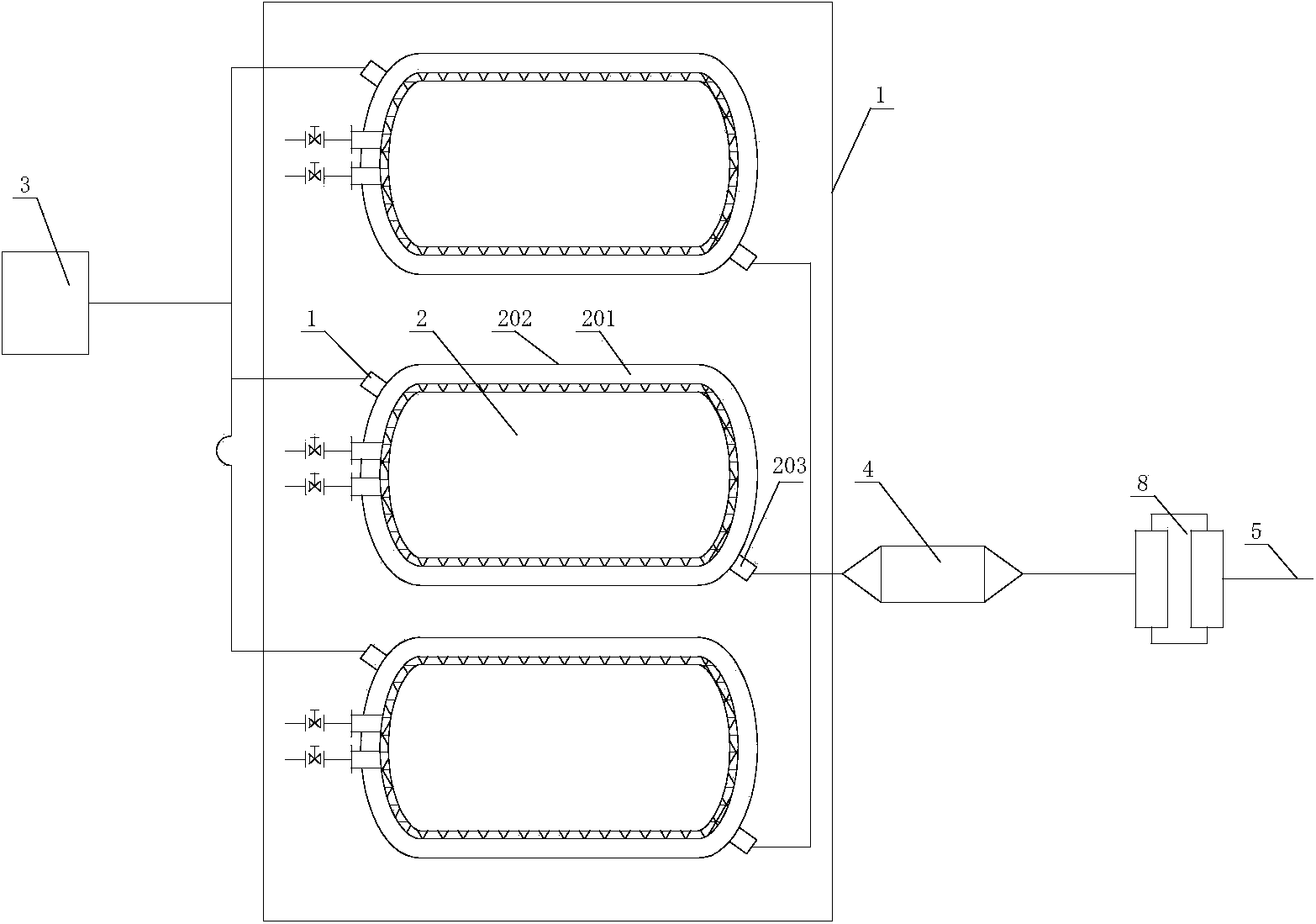

[0015] Example 1 as figure 1 As shown, a low-temperature heat-insulating gas cylinder vacuum system includes several gas cylinders 2 arranged in a vacuum heating room 1, the gas cylinder interlayer 201 communicates with the vacuum device 3, and the gas cylinder outer bladder 202 is provided with an inlet The air joint 203 and the air intake joint 203 communicate with the interlayer heating box 4, the dehumidifier 8, and the compressed air inlet pipe 5 sequentially through pipelines.

[0016] When vacuuming the low-temperature heat-insulating gas cylinder vacuum system as described above, firstly the compressed air enters the interlayer 201 of the gas cylinder from the dehumidifier 8 through the interlayer heating box 4 to heat the interlayer; then, the nitrogen gas is heated from the dehumidifier 8 through the interlayer The box 4 is heated and enters the gas cylinder interlayer 201 until the vacuum degree reaches the set value.

Embodiment 2

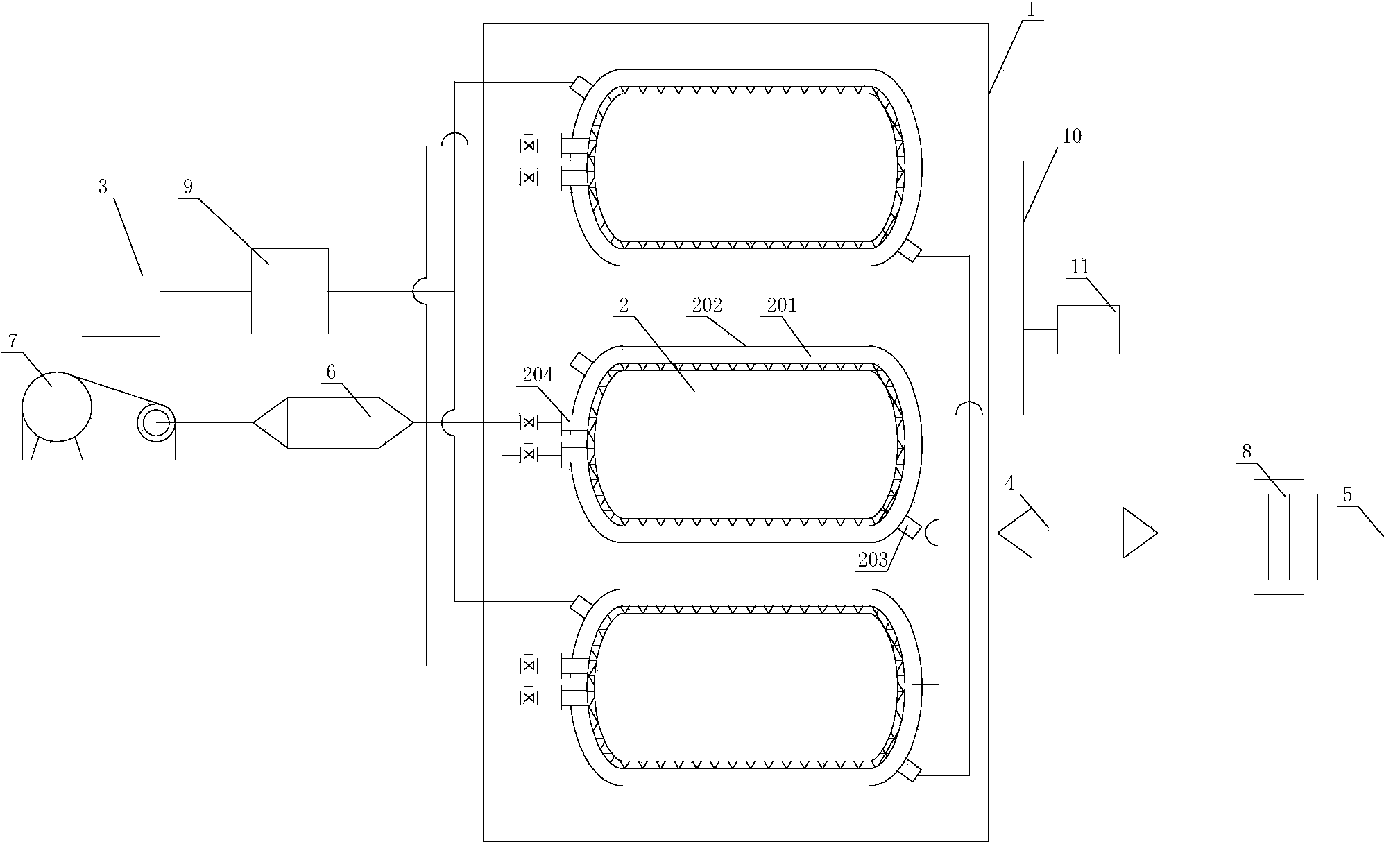

[0017] Example 2 as figure 2 As shown, a low-temperature heat-insulating gas cylinder vacuum system includes several gas cylinders 2 arranged in a vacuum heating room 1, the gas cylinder interlayer 201 communicates with the vacuum device 3, and the gas cylinder outer bladder 202 is provided with an inlet The air joint 203 and the air intake joint 203 communicate with the interlayer heating box 4 and the compressed air inlet pipe 5 sequentially through pipelines. The self-pressurizing port 204 of the gas cylinder liner is connected to the liner heating box 6 and the blower 7 in turn through pipelines. A dehumidifier 8 is provided between the interlayer heating box 4 and the compressed air inlet pipe 5 . A cold well 9 is provided between the gas cylinder interlayer 201 and the vacuum device 3 . The gas cylinders 2 are provided with a pressure-taking pipe 10 connecting the interlayers 201 of each gas cylinder, and a vacuum gauge 11 is provided on the pressure-taking pipe 10 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com